Method for measuring oil level of transformer oil conservator based on ultrasonic detection

A technology for ultrasonic detection and transformer oil, applied in measuring devices, liquid/fluid solid measurement, instruments, etc., can solve problems such as alarms, direct contact of lead wires or iron cores with air, and lower insulation levels of transformers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

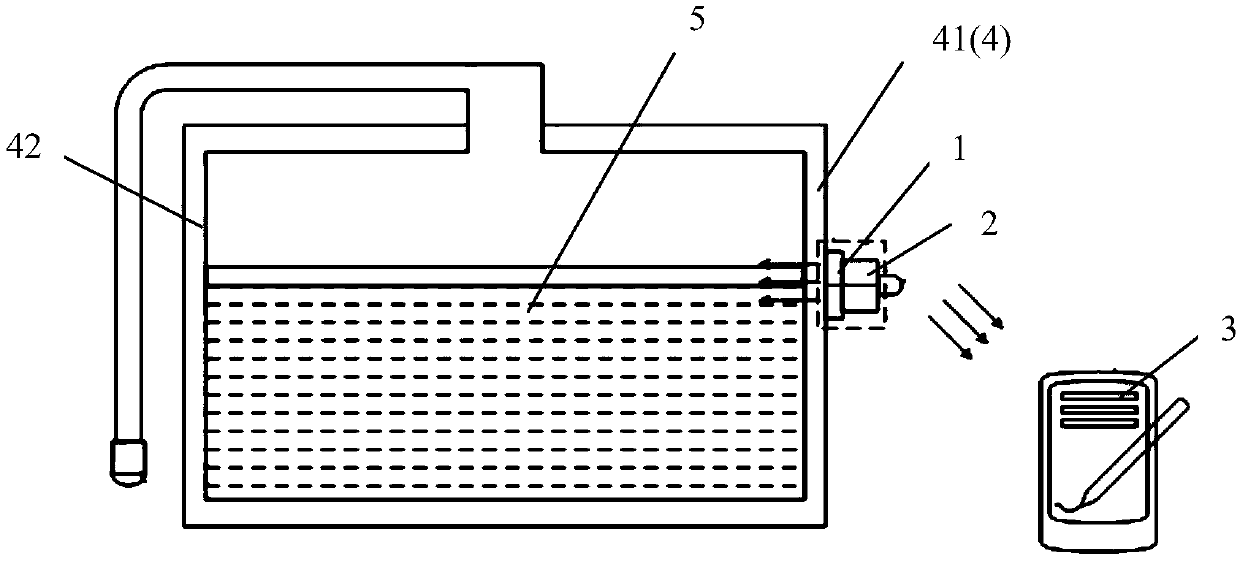

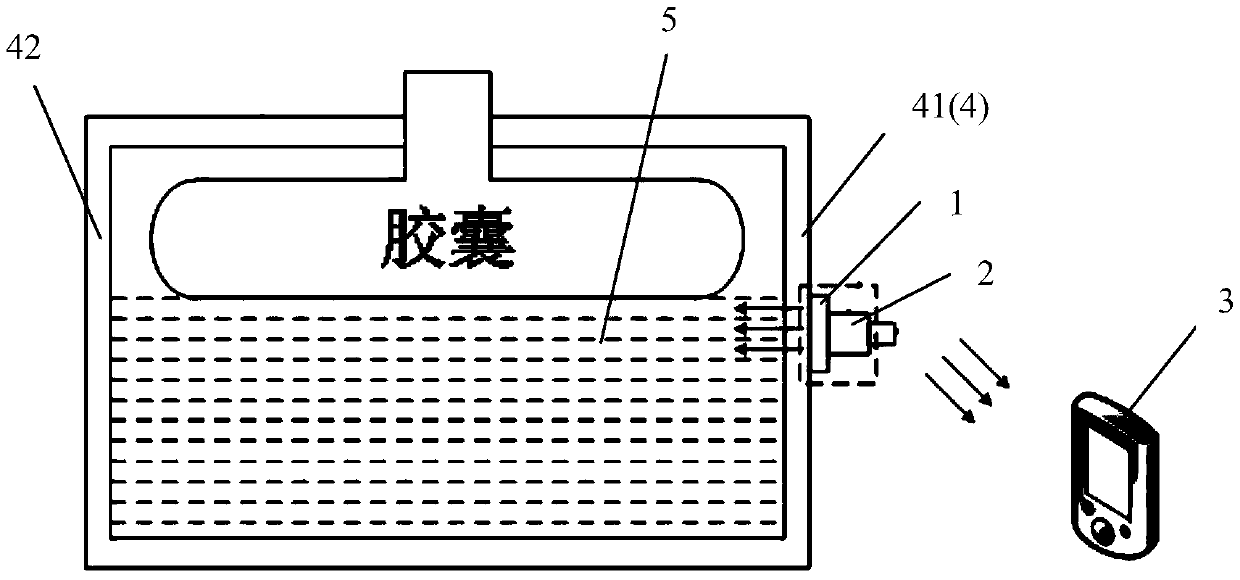

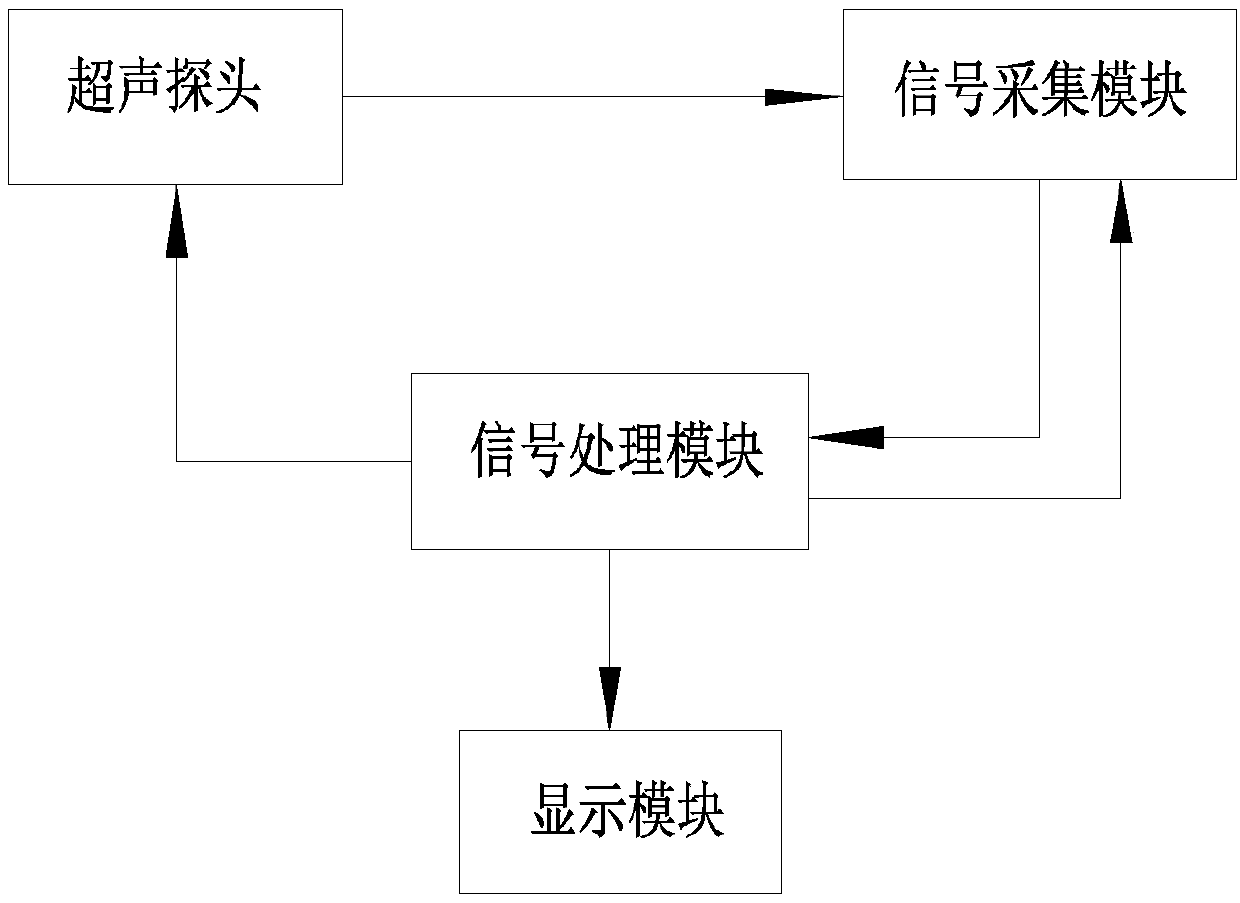

[0026] Please check Figure 1 to Figure 4 , the method for measuring the oil level of a transformer oil conservator based on ultrasonic detection is provided with an ultrasonic probe 1, a signal acquisition module 2, a signal processing module 3 with a microcontroller connected to the signal acquisition module 2 and a signal processing module 3 connected to the signal acquisition module 2 connected display module.

[0027] In this embodiment, the signal acquisition module 2 is installed together with the ultrasonic probe 1 so as to receive the reflected signal of the ultrasonic longitudinal wave emitted by the ultrasonic probe 1 .

[0028] In the present embodiment, the signal acquisition module 2 is provided with a microcontroller and communicated with the signal processing module 3, and the microcontroller of the signal processing module 3 adopts an ATmega128 single-chip microcomputer.

[0029] In addition, the signal acquisition module 2 can also be without a microcontroll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com