Low-power-consumption EMCCD high-voltage sine driving signal generation circuit

A driving signal generation and low power consumption technology, applied in the electronic field, can solve the problems of complex adjustment of frequency, phase and peak-to-peak value, miniaturization of cameras that cannot meet high readout rates, and limitation of circuit reliability and service life. Simplified production method, low power consumption, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

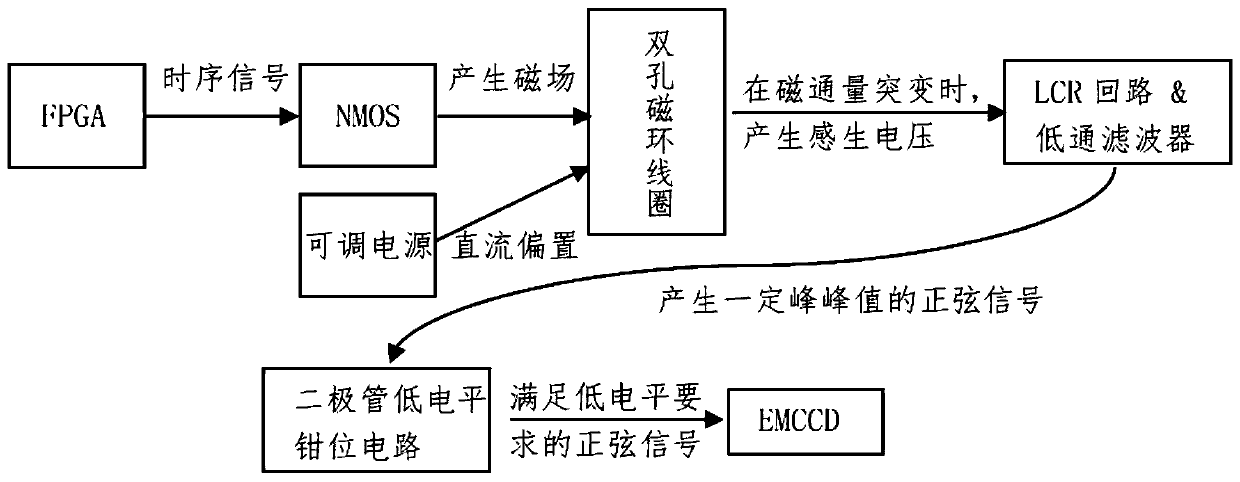

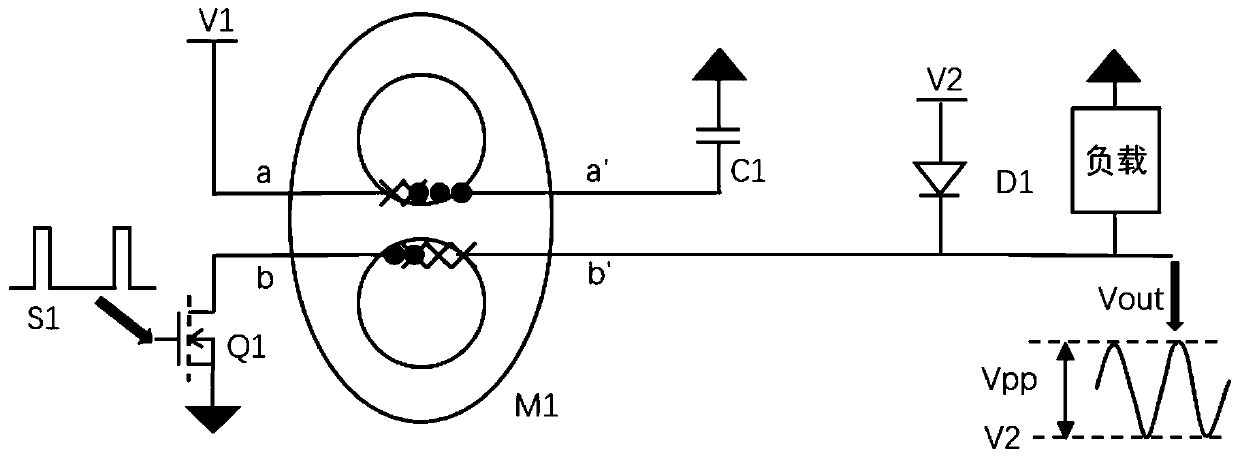

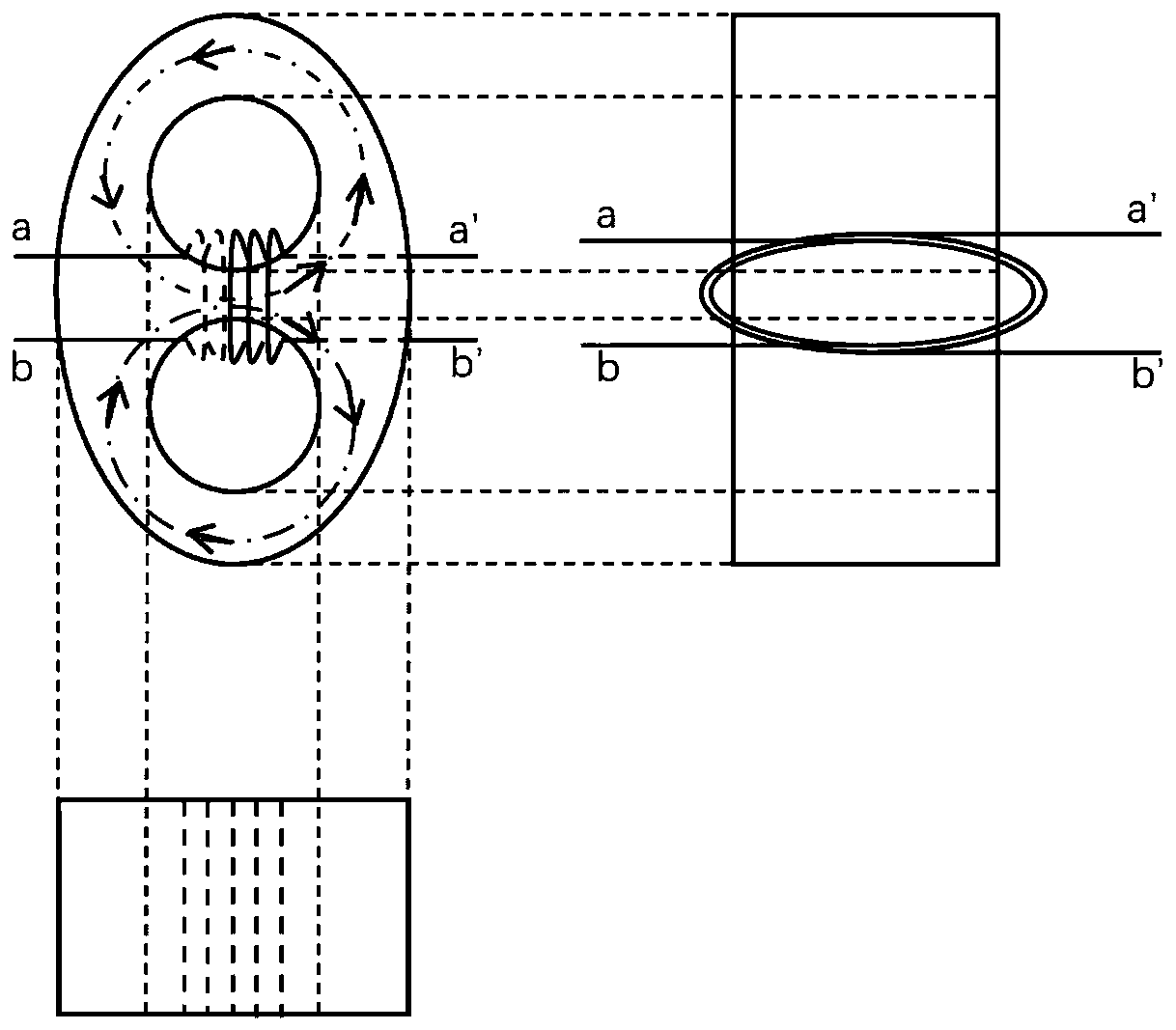

[0027] The invention is a low-power high-voltage sinusoidal drive signal generation circuit, including an enhanced NMOS tube, a double-hole magnetic ring coil, an LCR oscillating circuit and a diode level clamping circuit, such as figure 1 , figure 2 with image 3 shown. The square wave generated by the FPGA unit is connected to the gate of the NMOS tube, the drain of the NMOS tube is connected to the primary coil, and the source of the NMOS tube is grounded; the frequency and phase of the wave signal above the NMOS tube gate are controlled to adjust the frequency and phase of the sine wave. Frequency and phase; the duty cycle of the gate signal of the NMOS and the capacitance C in the LCR c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com