Hemostatic composite material and preparation method thereof

A composite material and hydrophilic polymer technology, which is applied in the field of hemostatic composite materials grafted with lithium magnesium silicate and hydrophilic polymers and its preparation, can solve the problems of poor dispersibility of lithium magnesium silicate, poor dispersibility of composite hemostatic materials, Inconvenient clinical operation for doctors and other problems, to achieve good hemostasis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

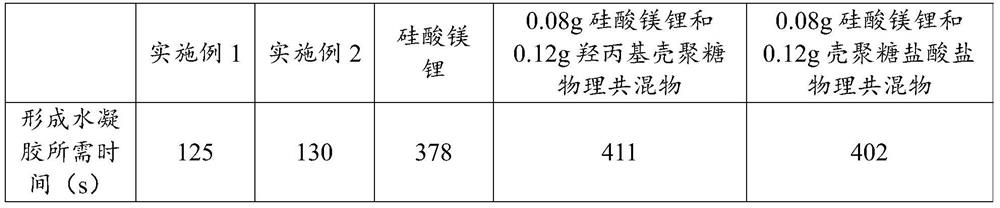

Examples

preparation example Construction

[0030] The preparation method of the hemostatic composite material of the present invention comprises the following steps: (1) mixing lithium magnesium silicate, a hydrophilic polymer, and a solvent to form a mixed suspension; (2) drying the mixed suspension to remove part Solvent; react the dried suspension under heating conditions, then cool and pulverize to obtain large particles of magnesium silicate grafted hydrophilic polymer; (3) graft lithium magnesium silicate with hydrophilic polymer The large particles are mixed with water, swollen and dispersed to obtain a lithium magnesium silicate grafted hydrophilic polymer hydrogel; (4) pre-freezing the lithium magnesium silicate grafted hydrophilic polymer hydrogel, and then freeze-drying, The magnesium lithium silicate grafted hydrophilic polymer with a porous structure is obtained; and then the porous magnesium lithium silicate grafted hydrophilic polymer is pulverized to obtain a hemostatic composite material.

[0031] The ...

Embodiment 1

[0049] The solvent (volume ratio of ethanol, acetone and water is 1:3:7) that 1.5g hydroxypropyl chitosan is formed with 28ml ethanol, acetone and water is mixed to form a mixed solution; 0.6g lithium magnesium silicate (silicon Lithium magnesium oxide is a flaky crystal with a diameter of 20nm and a thickness of 0.8nm) added to the mixed solution, and ultrasonicated at 150kHz for 60min to form a mixed suspension.

[0050] Dry the mixed suspension at 70°C for 4 hours to remove ethanol and acetone in the solvent; react the dried suspension at 120°C for 4 hours, then cool to room temperature and pulverize to obtain magnesium silicate with an average particle size of 300 μm Lithium-grafted hydrophilic polymer large particles.

[0051] Add 2 g of the prepared large particles of lithium magnesium silicate grafted hydrophilic polymer to 30 ml of deionized water, and stir for 4 minutes at 50° C. to swell and disperse the large particles of lithium magnesium silicate grafted hydrophil...

Embodiment 2

[0054] 1.6g chitosan hydrochloride is mixed with the solvent (the volume ratio of isopropanol, acetone and water is 1:3:7) that 28ml isopropanol, acetone and water are formed to form a mixed solution; 0.8g silicic acid Magnesium lithium (lithium magnesium silicate is a plate-like crystal with a diameter of 25nm and a thickness of 1.1nm) was added to the mixed solution, and ultrasonic was applied at 150kHz for 60min to form a mixed suspension.

[0055] Dry the mixed suspension at 70°C for 5 hours to remove isopropanol and acetone in the solvent; react the dried suspension at 120°C for 4 hours, then cool to room temperature and pulverize to obtain silicic acid with an average particle size of 300 μm Magnesium lithium grafted hydrophilic polymer large particles.

[0056] Add 2 g of the prepared large particles of lithium magnesium silicate grafted hydrophilic polymer to 30 ml of deionized water, and stir for 4 minutes at 50° C. to swell and disperse the large particles of lithium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com