Automatic superposition pulse single-pass welding system and method for stainless steel pipe abutting connection

A technology of superimposing pulses and stainless steel pipes, applied in welding equipment, welding accessories, metal processing, etc., can solve the problems of inability to meet welding penetration requirements, low S content of stainless steel pipes, etc., to achieve good weld formation and welding quality, good welding Seam forming and welding seam fusion, the effect of small welding operation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

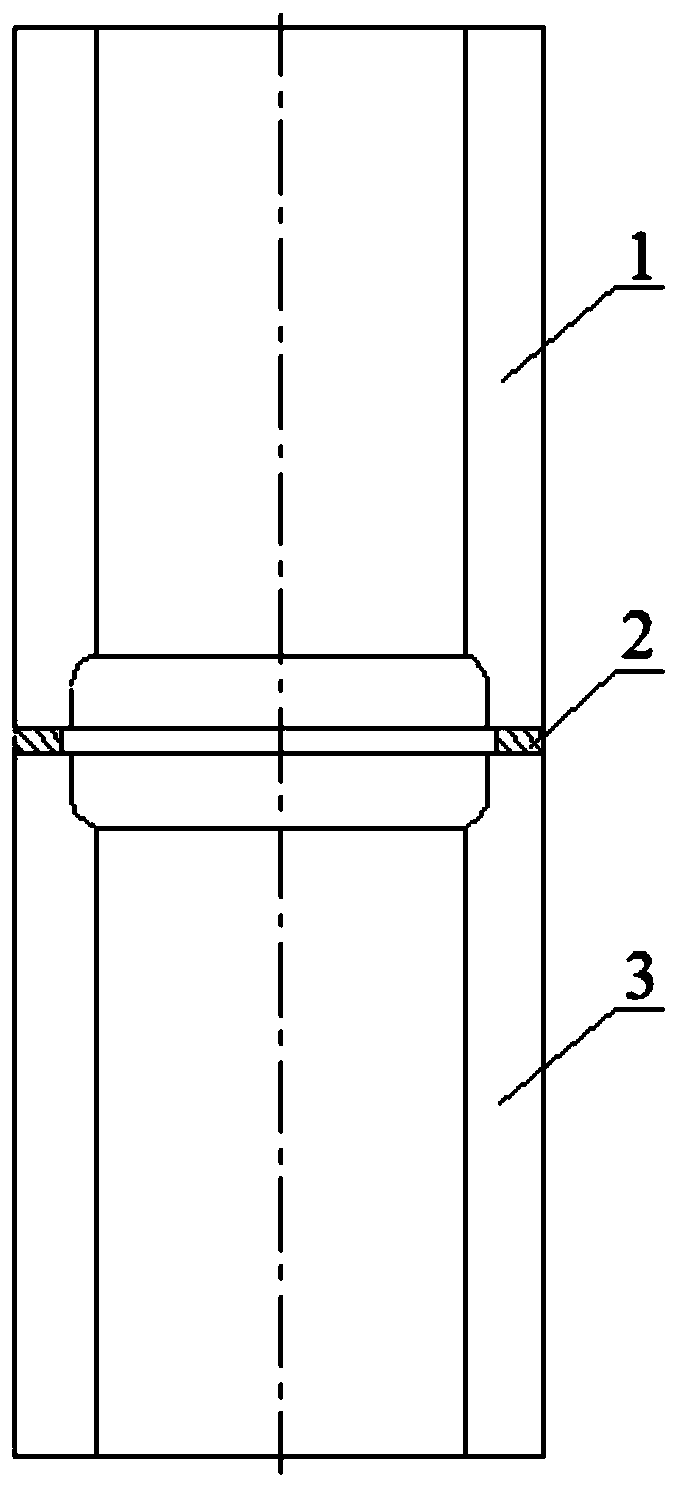

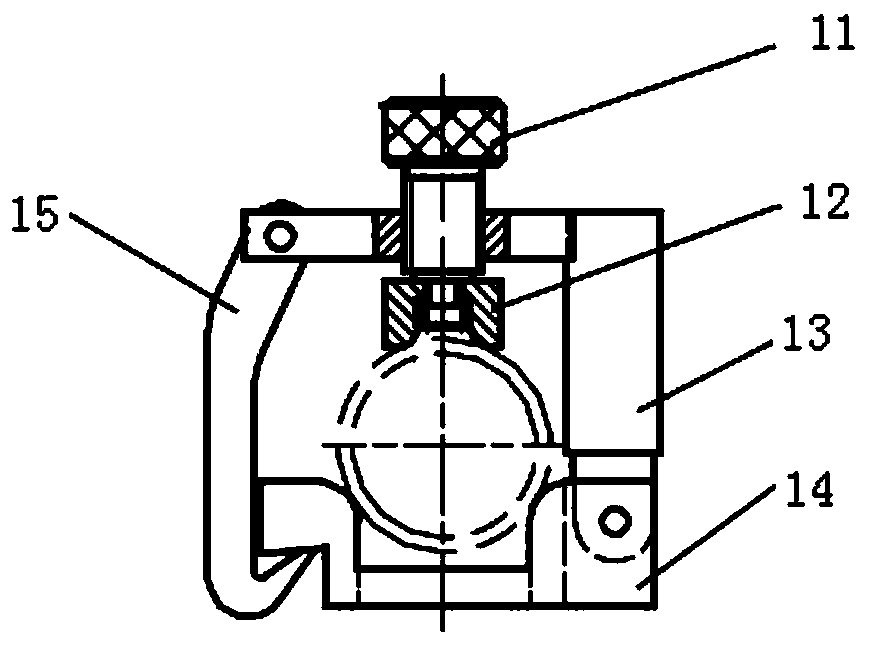

[0167] The inner diameter of the casing and connecting piece made of Z2CND18-12NS steel is 26mm, and the inner diameter of Z01CD26-01 steel is 28mm, and the melting ring is 0.5mm thick. After the butt joint, use image 3 and Figure 4 Positioning fixtures shown in are fixed and spot welded.

[0168] The positioning tool comprises a base 14 with a U-shaped structure with a flange, and the flange on one side is hinged with two legs of the support 13; The flange on the other side of the base 14 is hooked and connected. On the opposite side of the bracket 13 and the base 14, the locking screw 11 is connected with the pressing plate 12 in a U-shaped groove to fix the casing, the connecting piece and the melting ring.

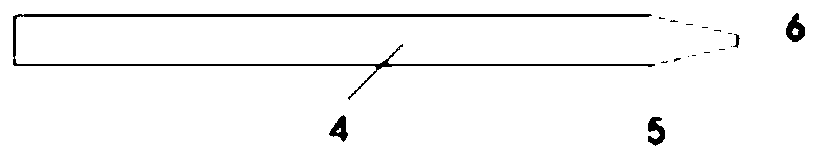

[0169] After spot welding, the positioning tool is removed, and the TIG welding machine performs automatic welding. Wherein, the diameter of the tungsten rod 4 is 2.4mm; the cone angle of the cone 5 at the tip of the tungsten pole is 33°; the diameter of the tip p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com