A kind of copper alloy and its preparation method and antenna material

A copper alloy and antenna technology, applied in the field of alloys, can solve the problems of affecting antenna performance, high cost, expensive Ag, etc., and achieve the effects of improved service life, low cost, good mechanical properties and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

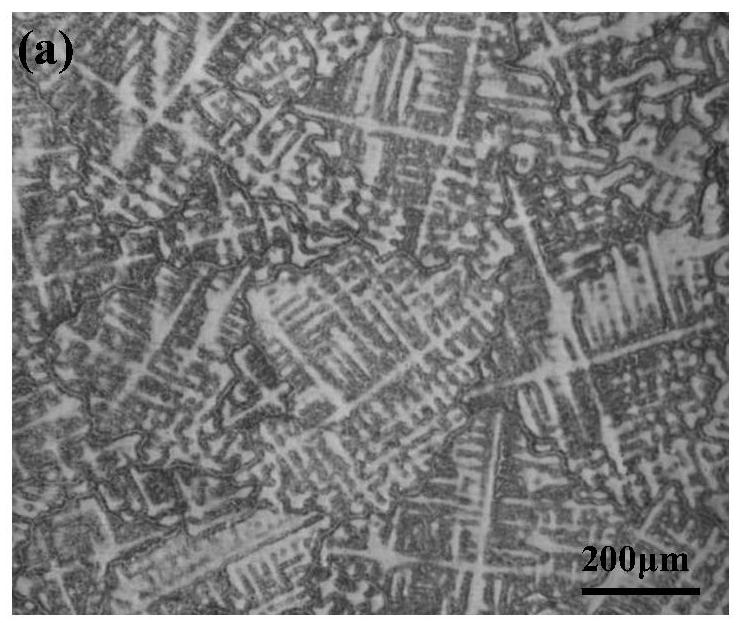

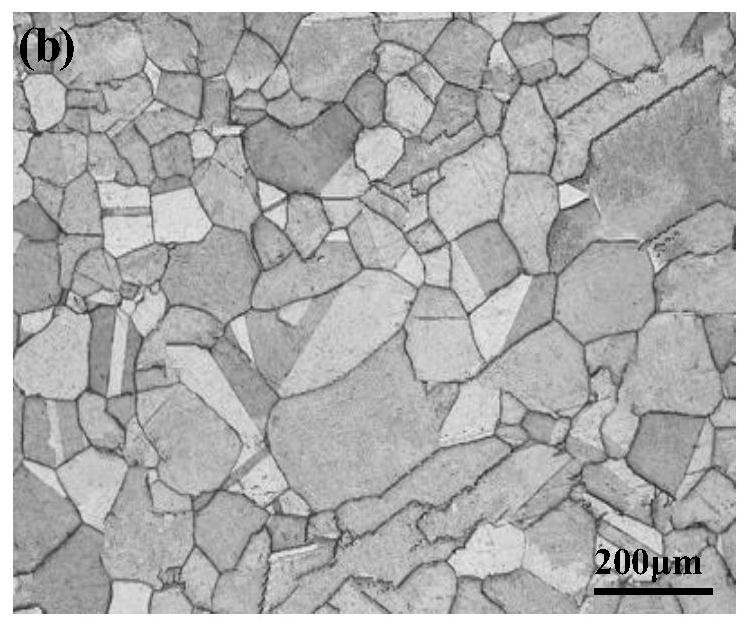

Image

Examples

Embodiment 1

[0044] Carry out batching according to following target composition, prepare copper alloy:

[0045] Mg 0.2wt%, Fe 0.4wt%, Sn 0.4wt%, Y 0.06wt%, balance Cu.

[0046] The magnesium source, iron source, tin source, yttrium source and copper source are smelted in a vacuum melting furnace, and the magnesium source and tin source are respectively wrapped with copper sheets and put into the vacuum melting furnace at a melting temperature of 1230°C. Stir continuously for 7 minutes after melting, and the stirring speed is 20 rpm.

[0047] Cast the smelted alloy liquid into a cylindrical quartz sand mold ingot mold. Before casting, use a brush to brush the mixture of alcohol and kerosene on the inner surface of the ingot mold as a release agent, then ignite it with fire, and repeat it twice. Utilize demoulding and improve the surface quality of the ingot obtained; the temperature of casting is 1230°C.

[0048] After the casting is completed, water cooling and demoulding are carried ou...

Embodiment 2

[0057] Carry out batching according to following target composition, prepare copper alloy:

[0058] Mg 0.2wt%, Fe 0.2wt%, Sn 0.2wt%, Y 0.1wt%, the balance is Cu.

[0059] The magnesium source, iron source, tin source, yttrium source and copper source are smelted in a vacuum melting furnace, and the magnesium source and tin source are respectively wrapped with copper sheets and put into the vacuum melting furnace at a melting temperature of 1220°C. Stir continuously for 7 minutes after melting, and the stirring speed is 20 rpm.

[0060] Cast the smelted alloy liquid into a cylindrical quartz sand mold ingot mold. Before casting, use a brush to brush the mixture of alcohol and kerosene on the inner surface of the ingot mold as a release agent, then ignite it with fire, and repeat it twice. Utilize demoulding and improve the surface quality of the ingot obtained; the temperature of casting is 1220°C.

[0061] After the casting is completed, water cooling and demoulding are carr...

Embodiment 3

[0068] Carry out batching according to following target composition, prepare copper alloy:

[0069] Mg 0.2wt%, Fe 0.2wt%, Sn 0.2wt%, Y 0.04wt%, balance Cu.

[0070] The magnesium source, iron source, tin source, yttrium source and copper source are smelted in a vacuum melting furnace, and the magnesium source and tin source are respectively wrapped with copper sheets and put into the vacuum melting furnace at a melting temperature of 1240°C. Stir continuously for 9 minutes after melting, and the stirring speed is 20 rpm.

[0071] Cast the smelted alloy liquid into a cylindrical quartz sand mold ingot mold. Before casting, use a brush to brush the mixture of alcohol and kerosene on the inner surface of the ingot mold as a release agent, then ignite it with fire, and repeat it twice. Utilize demoulding and improve the surface quality of the ingot obtained; the temperature of casting is 1240°C.

[0072] After the casting is completed, water cooling and demoulding are carried ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com