Alloy material for hot stamping die and preparation method thereof

A technology of hot stamping dies and alloy materials, applied in the direction of electrolytic coating, anodic oxidation, surface reaction electrolytic coating, etc., can solve the problems of insufficient high-temperature friction and wear performance, poor toughness, easy cracking and failure of molds, etc., and achieve good thermal stability , good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

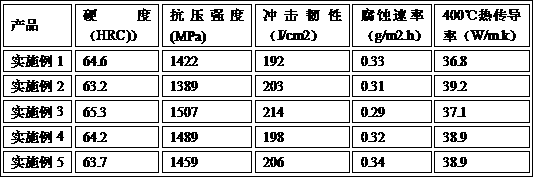

Examples

Embodiment 1

[0025] An alloy material for a hot stamping die, the chemical composition of the die material is: C: 0.46%; Si: 0.31%; Mn: 0.97%; Mo: 1.8%; V: 1.2% ; Ni: 1.36%; W 0.12%; Er: 0.20%; Y: 0.10%;

[0026] The present invention also describes the preparation method of the alloy material for the hot stamping die, comprising the steps of:

[0027] (1) According to the above ratio, put the raw materials into the electric arc furnace for smelting, and then pour the steel ingot under vacuum condition after refining. After the steel ingot is cooled, it will be annealed at 825°C to relieve stress, and the electrode billet will be obtained;

[0028] (2) Place the electrode blank in electroslag remelting and place it in an electroslag remelting furnace under the protection of an inert gas for electroslag remelting treatment to obtain an electroslag ingot; then anneal the electroslag ingot at 850°C;

[0029] (3) Put the electroslag ingot into a high-frequency induction melting furnace, heat ...

Embodiment 2

[0034] An alloy material for a hot stamping die, the chemical composition of the die material is: C: 0.50%; Si: 0.29%; Mn: 1.12%; Mo: 1.6%; V: 1.35%; Ni : 1.2%; W 0.15%; Er: 0.15%; Y: 0.08%; the balance Fe.

[0035] The present invention also describes the preparation method of the alloy material for the hot stamping die, comprising the steps of:

[0036] (1) According to the above ratio, the raw materials are put into the electric arc furnace for smelting, and then the steel ingot is poured under vacuum conditions after refining, and the steel ingot is cooled and annealed at 850 ° C to relieve stress, and the electrode billet is obtained;

[0037] (2) Place the electrode blank in electroslag remelting and place it in an electroslag remelting furnace under the protection of an inert gas for electroslag remelting treatment to obtain an electroslag ingot; then anneal the electroslag ingot at 850°C;

[0038] (3) Put the electroslag ingot into a high-frequency induction melting f...

Embodiment 3

[0043] An alloy material for a hot stamping die, the chemical composition of the die material is: C: 0.42%; Si: 0.32%; Mn: 0.95%; Mo: 1.73%; V: 1.15%; Ni : 1.38%; W 0.15%; Er: 0.18%; Y: 0.15%; the balance Fe.

[0044] The present invention also describes the preparation method of the alloy material for the hot stamping die, comprising the steps of:

[0045] (1) According to the above ratio, the raw materials are put into the electric arc furnace for smelting, and then the steel ingot is poured under vacuum condition after refining, and the steel ingot is cooled and annealed at 820°C to relieve stress, and the electrode billet is obtained;

[0046] (2) Place the electrode blank in electroslag remelting and place it in an electroslag remelting furnace under the protection of an inert gas for electroslag remelting treatment to obtain an electroslag ingot; then anneal the electroslag ingot at 850°C;

[0047] (3) Put the electroslag ingot into a high-frequency induction melting furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com