A Calculation Method of Infrared Fitting Calculation of Chitosan Deacetylation Degree

A calculation method and technology of deacetylation degree, which are used in instruments, measuring devices, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

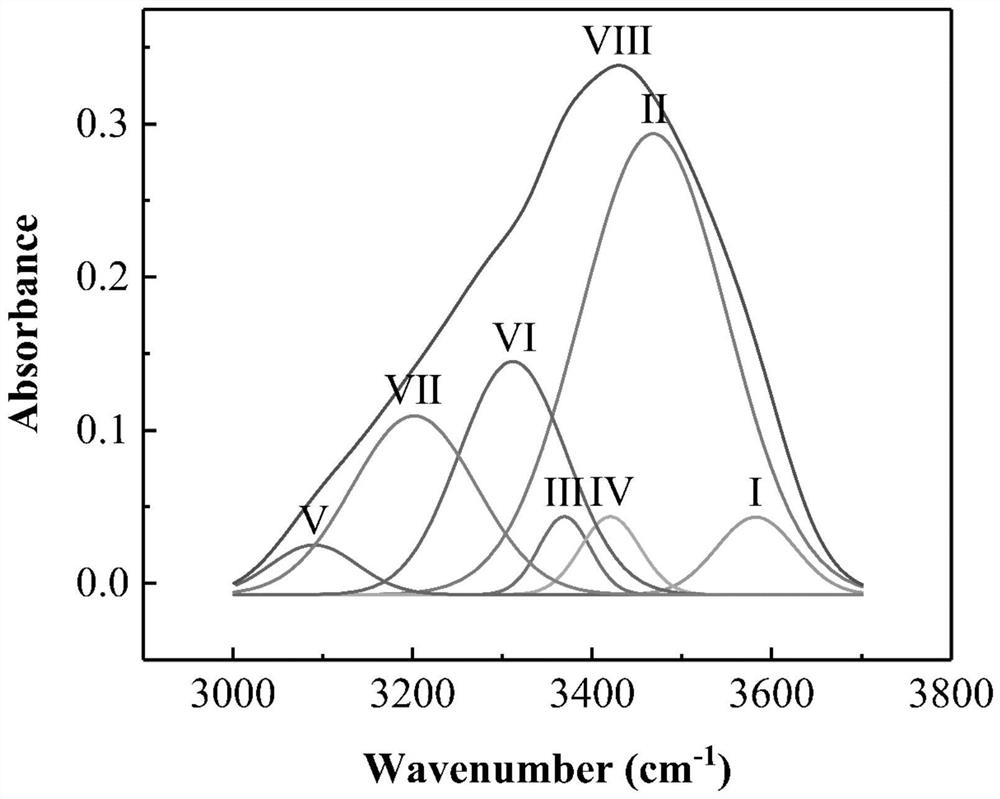

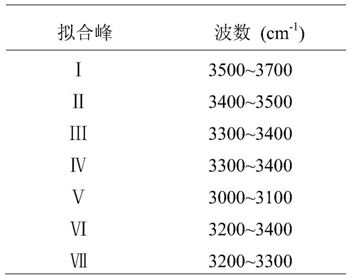

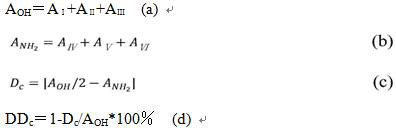

[0037] Infrared fitting calculation method to calculate the degree of deacetylation of chitosan:

[0038] (1) Take by weighing 0.0011g of chitosan to be measured (degree of deacetylation, DD 93.8%) and 0.1100g of potassium bromide powder in an amber mortar, both are ground to fine;

[0039] (2) Send the mixed powder obtained through grinding in step (1) to a tablet machine for tableting, and press for 5 minutes under a pressure of 50 MPa;

[0040] (3) Utilize the Fourier transform infrared instrument to the tablet that obtains in step (2) at 400-4000cm -1 Carry out scanning test in the range of wave number, obtain absorbance spectrogram, promptly obtain the chitosan infrared spectrogram to be tested;

[0041] (4) carry out baseline correction and smoothing processing in the infrared spectrogram data that obtains in step (3) in OMNIC software; Wherein, baseline correction can adopt automatic baseline correction, and the smoothing point number of smoothing processing is 25 poin...

Embodiment 2

[0060] According to the infrared fitting calculation method described in the steps (1)~(6) of embodiment 1, calculate the degree of deacetylation of chitosan to be measured, wherein the steps different from the present embodiment in embodiment 1 are:

[0061] In step (1), weigh 0.0013g of chitosan to be tested (degree of deacetylation, DD 86.4%) and 0.1300g of potassium bromide powder in an amber mortar, and grind the two until fine.

[0062] The fitting peak I-VI obtained in step (5), the peak area percentage A of the fitting peak I-VI Ⅰ -A Ⅵ followed by A Ⅰ =5.3, A Ⅱ = 44.1, A Ⅲ =0.7,A Ⅳ =16.0,A Ⅴ =1.0,A Ⅵ = 0.8.

[0063] As a verification example of the results obtained with the infrared fitting calculation method of the present embodiment, the existing ultraviolet spectrometry and potentiometric titration are used to measure the deacetylation degree of the same chitosan (deacetylation degree, DD 86.4%) , the specific assay method is the same as in Example 1.

[00...

Embodiment 3

[0066] According to the infrared fitting calculation method described in the steps (1)-(6) of embodiment 1, calculate the degree of deacetylation of chitosan to be measured, wherein the steps that embodiment 1 is different from the present embodiment are:

[0067] In step (1), weigh 0.0014g of chitosan (degree of deacetylation, DD 75.9%) and 0.1400g of potassium bromide powder in an amber mortar, and grind the two until fine.

[0068] The fitting peaks I~VI obtained in step (5), the peak area percentage A of the fitting peaks I~VI Ⅰ -A Ⅵ followed by A Ⅰ =9.6,A Ⅱ = 41.1, A Ⅲ =0.3,A Ⅳ = 0, A Ⅴ =1.1,A Ⅵ = 12.5.

[0069] As a verification example of the results obtained with the infrared fitting calculation method of the present embodiment, the existing ultraviolet spectrometry and potentiometric titration are used to measure the deacetylation degree of the same chitosan (deacetylation degree, DD 86.4%) , the specific assay method is the same as in Example 1.

[0070] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com