Non-contact online monitoring method for electrode ablation of arc heating equipment

An arc heating and non-contact technology, which is applied in measuring devices, color/spectral characteristic measurement, and material analysis through optical means, can solve the problem of unclear specific mechanism, unclear main influencing factors, and lack of real-time electrode ablation. Monitoring and other issues to achieve fast response and real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

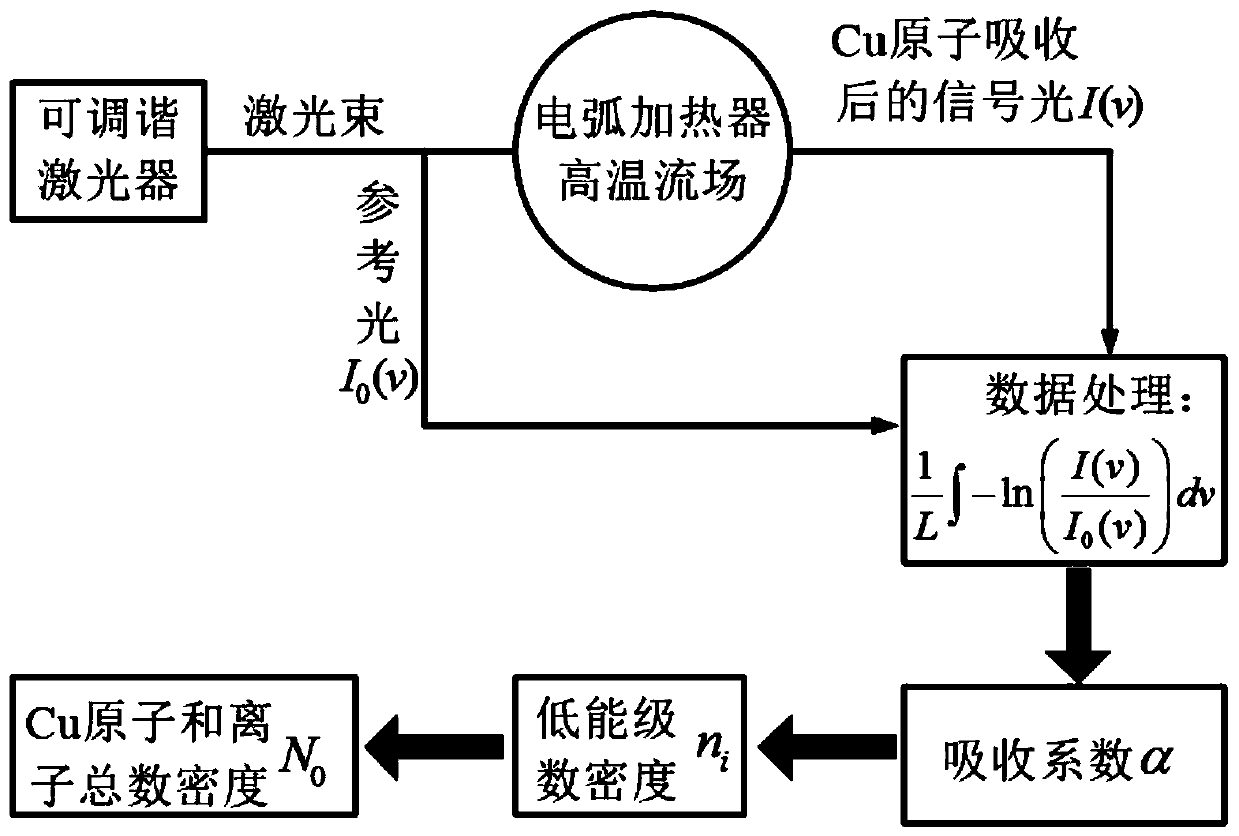

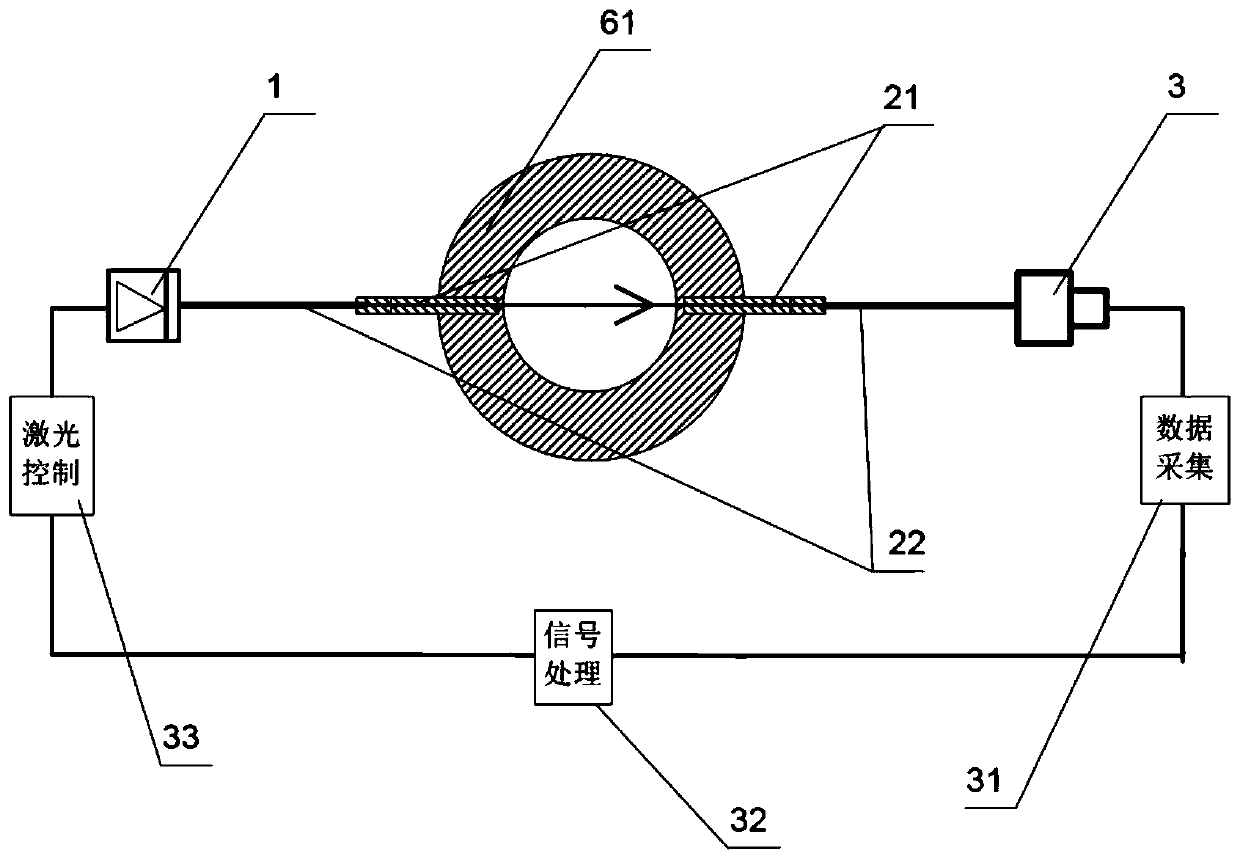

[0049] A non-contact online monitoring method for electrode ablation of arc heating equipment, comprising the following steps:

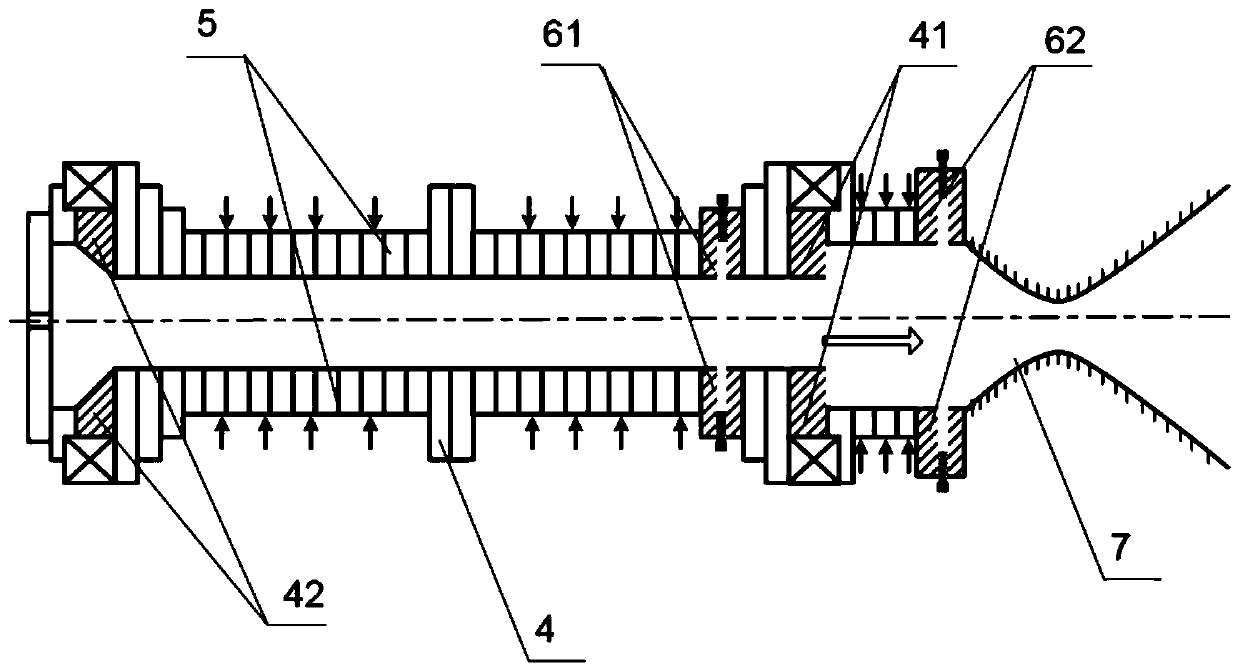

[0050] Step 1. The arc heating equipment chooses a sheet-type arc heating equipment. The copper front electrode and copper rear electrode in the arc heating equipment are discharged to heat the gas passing through it. The heated gas forms a high-temperature flow field, and the high-temperature flow field passes through the nozzle. An ultra-high-speed airflow field is formed. At this time, there are copper atoms or copper ions formed after the electrodes are burned in the high-temperature flow field;

[0051] Step 2. The laser uses a distributed feedback diode laser (DFB) with a center wavelength of 793.3nm. The laser beam is output through fiber coupling. At this time, the laser wavelength matches the spectral line of the copper atomic absorption spectrum, and the laser emits a laser beam. The laser beam It emits from one end of the flange of the las...

Embodiment 2

[0065] This embodiment is basically the same as the embodiment 1, the main difference is that the laser used is a distributed feedback diode laser (DFB) with a center wavelength of 809.3 nm. The temperature of the high-temperature flow field can be obtained from the state parameters of the arc heater. Under the condition of thermodynamic equilibrium, the number density of low energy levels n i and the total atomic number density N A Satisfy the Boltzmann relationship between them, through the spectral database, use the normalization condition of the linear function to calculate the area of the absorption curve, and the number density n of Cu atoms can be obtained i , using the Boltzmann relationship to obtain the Cu atomic number density, and considering the number of Cu ion particles formed by the ionization of Cu atoms at high temperature, after data processing, the following can be obtained: Figure 4 When the shown copper atoms have laser wavelengths of 793.3nm and 809....

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com