Polyester film photovoltaic backboard with high hydrolysis resistance

A technology of polyester film and photovoltaic backsheet, applied in the field of composite materials, can solve the problems of high unidirectional shrinkage rate, can not meet the thermal shrinkage rate of solar cell backsheet, etc., achieve low thermal shrinkage rate, meet performance requirements, and be environmentally friendly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

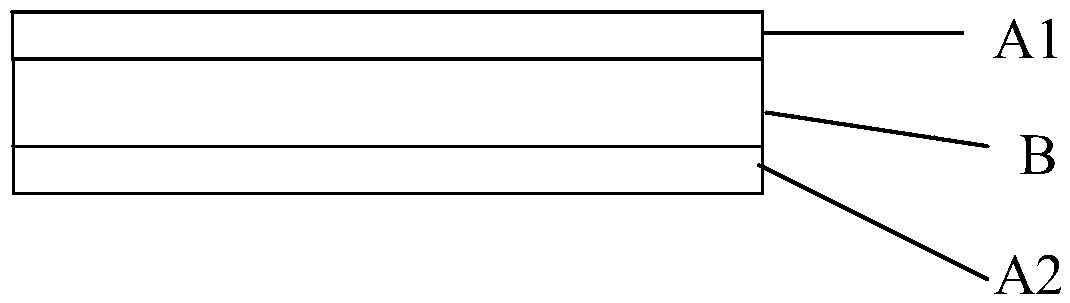

Image

Examples

Embodiment 1

[0049] In this embodiment, the polyethylene terephthalate-1,4-cyclohexanedimethanol ester used in the upper surface layer A1 or the lower surface layer A2 is 1,4-cyclohexanedimethanol (CHDM) with a molar content of 50% of the total molar content of ethylene glycol and 1,4-cyclohexanedimethanol (CHDM), the specific component content of the upper surface layer A1 or the lower surface layer A2 is as follows:

[0050] The polyethylene terephthalate-1,4-cyclohexanedimethanol is 97wt.%, and the total amount of various additives is 3wt.%.

[0051] The substrate layer B is prepared from titanium dioxide white pigment and polyethylene terephthalate. In this embodiment, the specific component content of the substrate layer B is as follows:

[0052] The polyethylene terephthalate is 94wt.%, the total amount of various additives is 3wt.%, and the titanium dioxide white pigment is 3wt.%.

[0053] The preparation method of the highly hydrolysis-resistant polyester film photovoltaic backpla...

Embodiment 2

[0059] Used in this example, polyethylene terephthalate-1,4-cyclohexanedimethanol is 1,4-cyclohexanedimethanol (CHDM) with a molar content of ethylene glycol and 1,4 -80% of the total molar content of cyclohexanedimethanol (CHDM), the preparation method of other raw materials, substrate layer B and highly hydrolysis-resistant polyester film photovoltaic backplane is the same as that of Example 1.

Embodiment 3

[0061] The polyethylene terephthalate-1,4-cyclohexanedimethanol used in this example is 1,4-cyclohexanedimethanol (CHDM) with a molar content of ethylene glycol and 1,4- The total molar content of cyclohexanedimethanol (CHDM) is 100%, the preparation method of other raw materials, substrate layer B and highly hydrolysis-resistant polyester film photovoltaic backboard is the same as that of Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap