Coarse slime separation method and equipment thereof

A coarse coal slime and sorting technology, which is applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of coarse water running under the sieve, poor concentration efficiency, high investment cost, etc., and achieves convenient production management and low power consumption. The effect of lowering and angle adjustment is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

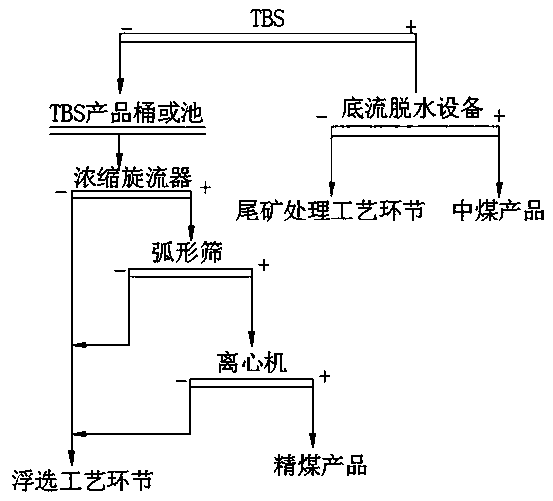

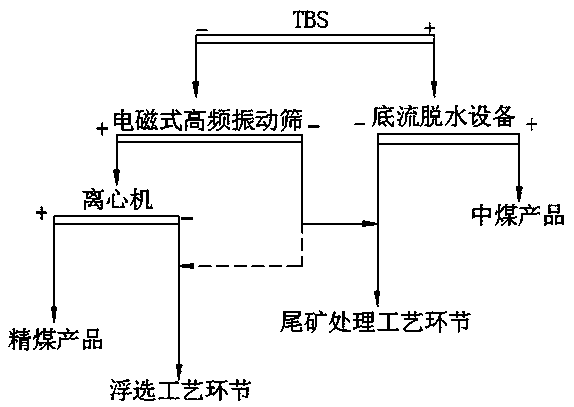

[0012] The coarse coal slime separation method is realized by the following steps: 1) The coarse coal slime is sorted by TBS; 2) The TBS overflow is sent to the electromagnetic high-frequency vibrating screen for pre-dehydration; 3) The electromagnetic high-frequency vibrating screen The screened material is finally dehydrated by a coal slime centrifuge to obtain clean coal products; the screened material (according to the ash content index) of the electromagnetic high-frequency vibrating screen enters the flotation process or tailings treatment process for subsequent treatment.

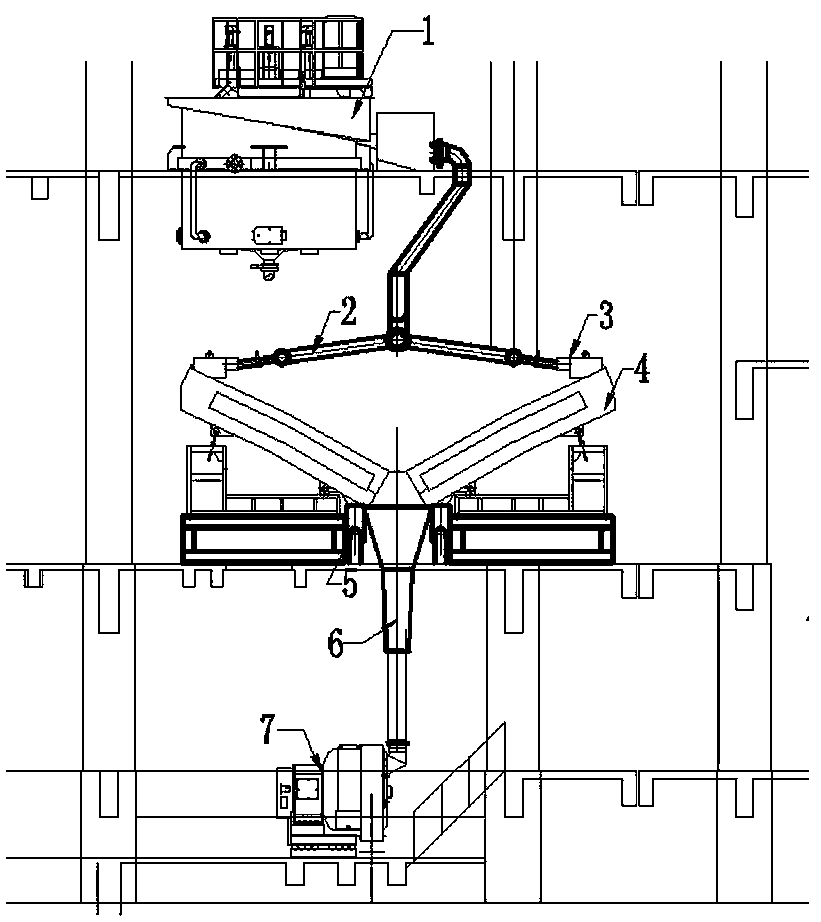

[0013] Coarse slime sorting equipment, including TBS1, the overflow port of TBS1 is connected to the feeder 2 through the pipeline, the feeder 2 is connected to the feeding box 3 of the electromagnetic high-frequency vibrating screen 4, and the electromagnetic high-frequency vibrating screen 4 The oversize discharge position of the sieve accepts a blanking chute 6, the outlet of the blanking chute 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com