An Intelligent Image Analysis System for Railway Cargo Inspection Robot

A technology of robot intelligence and image analysis, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of incomplete inspection process records, high work intensity, single inspection methods, etc., and achieve stable and reliable wireless communication and high protection level. , the effect of long transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

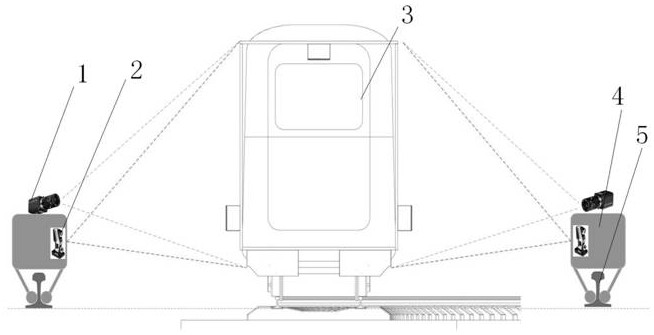

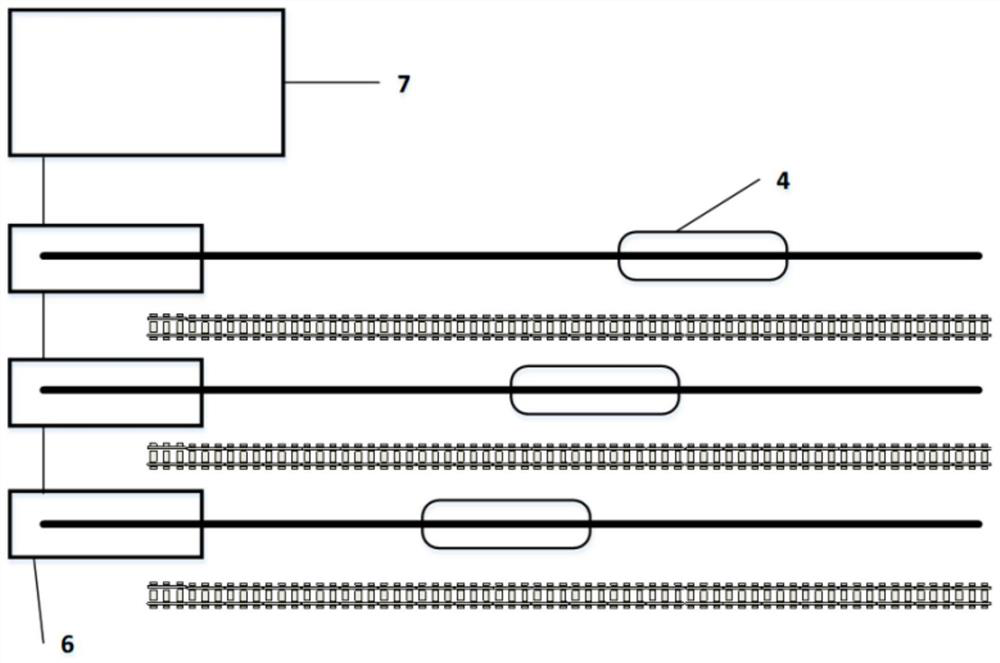

[0025] Combine below Figure 1-4 The present invention will be further described with specific embodiments.

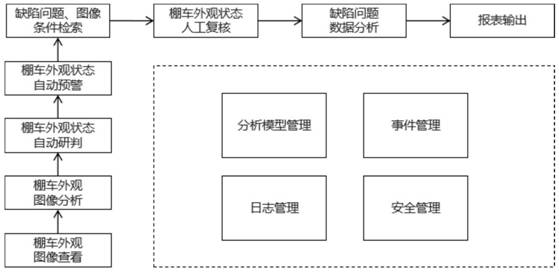

[0026] An intelligent image analysis system for a railway cargo inspection robot, including a front-end intelligent video image acquisition subsystem, a back-end artificial intelligence image analysis and processing subsystem, a network communication and a power supply subsystem; wherein, the intelligent video image acquisition subsystem collects The video image data of the appearance state of the freight boxcar and the loading state of the cargo are transmitted to the artificial intelligence image analysis and processing subsystem through the station communication system; the artificial intelligence image analysis and processing subsystem processes the acquired video image data into a recognizable data format and Carry out information matching, image intelligent analysis, information labeling and information release. According to different vehicle models, after obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com