Synthesis method of silicon disulfide powder

A synthesis method and technology of silicon sulfide, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of low efficiency, high cost, and difficulty in realizing industrialized production, and achieve environmental friendliness, low cost, and easy industrialization implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

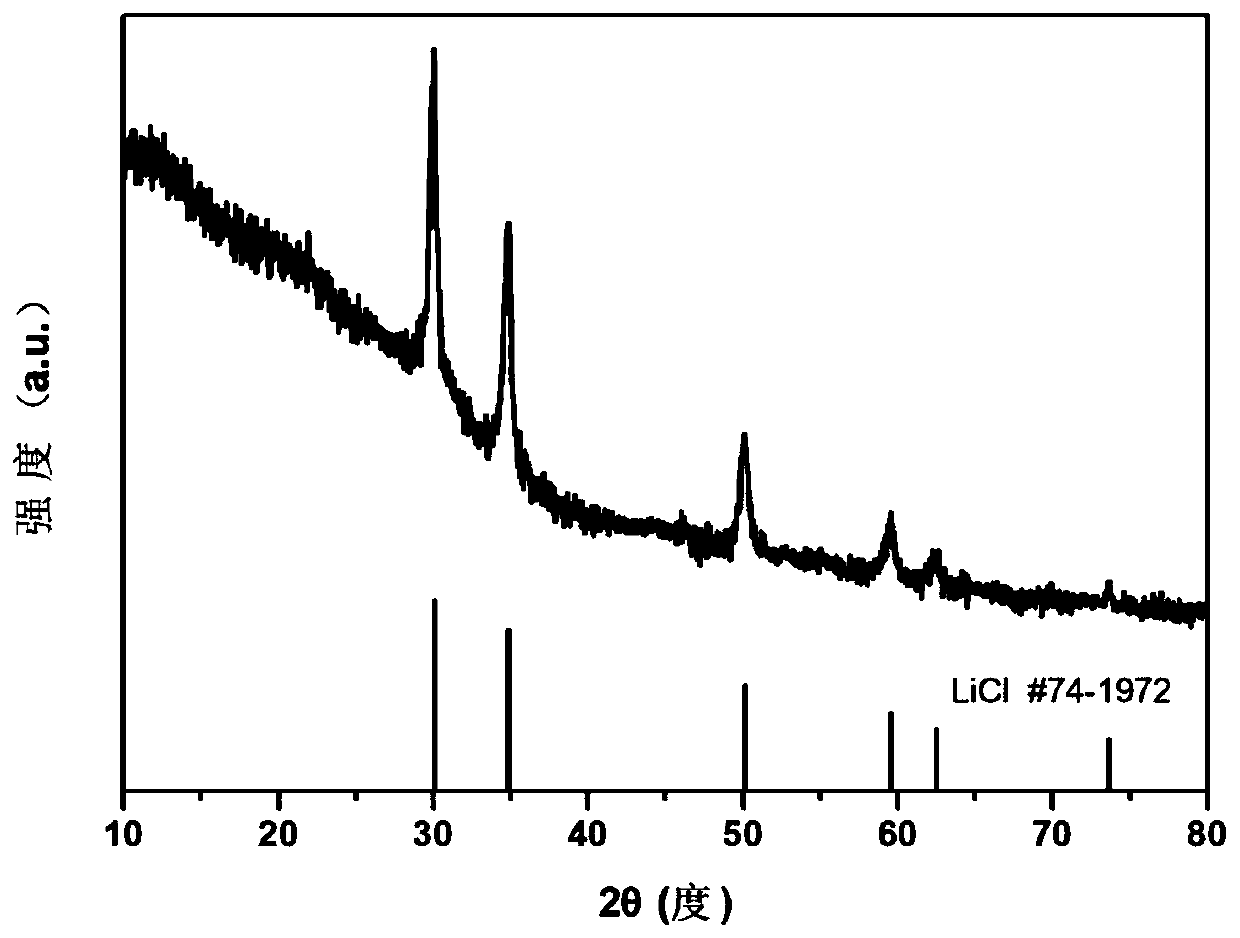

[0025] Under the protection of a nitrogen atmosphere, lithium sulfide and silicon tetrachloride were uniformly mixed at a molar ratio of 2:1, transferred to a reactor and sealed. Heat to 140°C at a heating rate of 2°C / min, and keep the temperature for 5h. After the reaction was completed, the temperature was lowered to room temperature, and excess silicon tetrachloride was recovered by distillation at 100°C. Add the solid product in the reactor to benzene, through solid-liquid separation, obtain a benzene solution containing silicon sulfide, recover benzene by distillation at 120°C, and dry the solid in it at 100°C to obtain silicon sulfide powder . figure 1 The X-ray diffraction pattern of its product can only characterize the X-ray pattern of lithium chloride. According to the law of conservation of materials, there must be silicon sulfide in the product.

Embodiment 2

[0027] Under the protection of an argon atmosphere, lithium sulfide and silicon tetrachloride were evenly mixed at a molar ratio of 1:1, transferred to a reactor and sealed. Heat to 100°C at a heating rate of 0.5°C / min, and hold for 100h. After the reaction was completed, the temperature was lowered to room temperature, and excess silicon tetrachloride was recovered by distillation at 60°C. Add the solid product in the reactor to benzene, through solid-liquid separation, obtain a benzene solution containing silicon sulfide, recover benzene by distillation at 85°C, and dry the solid in it at 100°C to obtain silicon sulfide powder .

Embodiment 3

[0029] Under the protection of a nitrogen atmosphere, lithium sulfide and silicon tetrachloride were uniformly mixed at a molar ratio of 2:3, transferred to a reactor and sealed. Heat to 300°C at a heating rate of 20°C / min, and hold for 1h. After the reaction was completed, the temperature was lowered to room temperature, and excess silicon tetrachloride was recovered by distillation at 80°C. Add the solid product in the reactor to benzene, through solid-liquid separation, obtain a benzene solution containing silicon sulfide, recover benzene by distillation at 90°C, and dry the solid in it at 100°C to obtain silicon sulfide powder .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com