High-energy-density explosive compound and preparation method thereof

A technology with high energy density and composites, which is applied in explosives processing equipment, explosives, offensive equipment, etc., can solve problems that cannot meet the needs of advanced warheads, and achieve the effect of improving reaction completeness, increasing concentration, and increasing energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

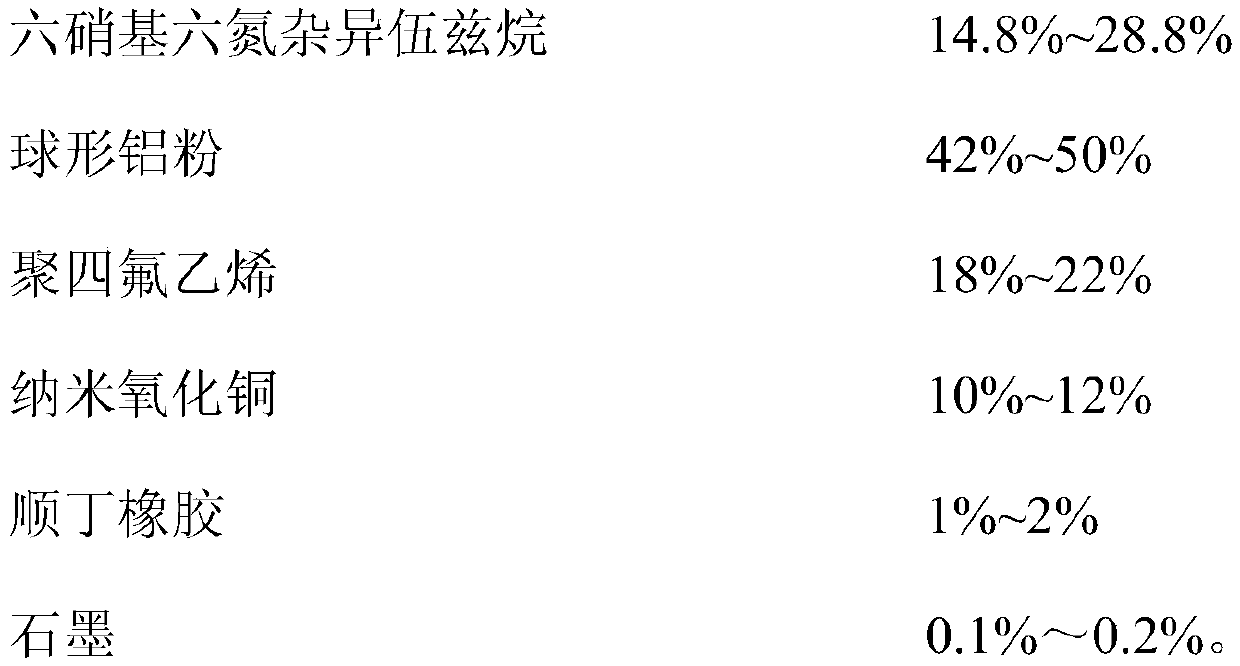

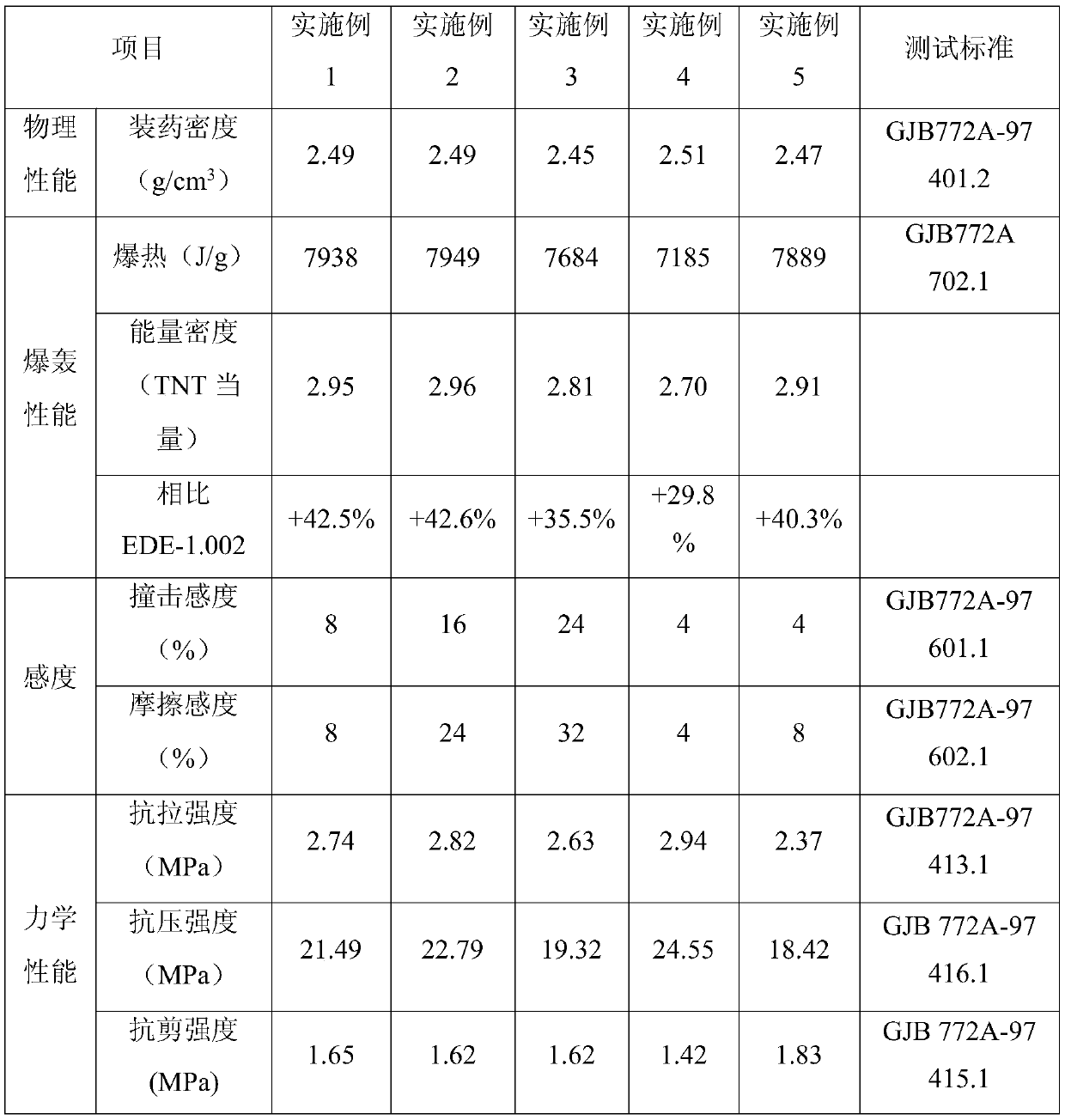

Embodiment 1

[0015] This embodiment is carried out according to the following mass percentage composition: 19.8% hexanitrohexaazaisowurtzitane; 47% aluminum powder; 20% polytetrafluoroethylene; 12% nano-copper oxide; 1% butadiene rubber; 0.2% graphite.

[0016] Preparation of this example

[0017] (1) Preparation of ternary mechanically activated particles: Add 470g of spherical aluminum powder, 200g of polytetrafluoroethylene, and 120g of nano-copper oxide into a high-energy ball mill, add 1600mL of ethanol as a ball milling aid, control the operating speed to 875 times / min, and ball mill for 60min. Discharge and dry at 40°C.

[0018] (2) Explosives and composite particles are evenly dispersed: 790g ball milled aluminum powder, polytetrafluoroethylene, nano copper oxide composite material and 198g hexanitrohexaazaisopentazane are added to the colloid mill, and the colloid mill is set The gap is 0.2mm, add 1500mL of ethanol, and cut for 30min to obtain a sample uniformly mixed with alumin...

Embodiment 2

[0023] This embodiment is carried out according to the following composition by mass percentage: 20% hexanitrohexaazaisowurtzitane; 47% aluminum powder; 20% polytetrafluoroethylene; 12% nano-copper oxide; 1% butadiene rubber; 0.1% graphite. The preparation steps refer to Example 1.

[0024] The performance test data shows that the charge density of this implementation is 2.49g / cm 3 , detonation heat 7949J / g, energy density increased by 42.6% compared with EDE-1.002, reaching 2.96 times TNT equivalent, moderate sensitivity, good mechanical properties.

Embodiment 3

[0026] This embodiment is implemented according to the following mass percentage composition: 28.8% Octogen; 42% aluminum powder; 18% polytetrafluoroethylene; 10% nano-copper oxide; 1% vinylidene fluoride, perfluoropropylene copolymer; 0.2% graphite. The preparation steps refer to Example 1.

[0027] The performance test data shows: this embodiment this implementation charge density 2.45g / cm 3 , detonation heat 7684J / g, energy density increased by 35.5% compared with EDE-1.002, reaching 2.81 times TNT equivalent, moderate sensitivity, good mechanical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Hot | aaaaa | aaaaa |

| Hot | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com