Chicory polysaccharide as well as extraction process and application thereof

An extraction process, the technology of chicory polysaccharides, which is applied in the direction of medical preparations containing active ingredients, organic active ingredients, bone diseases, etc., can solve problems such as imperfections, and achieve the effect of simple extraction and high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

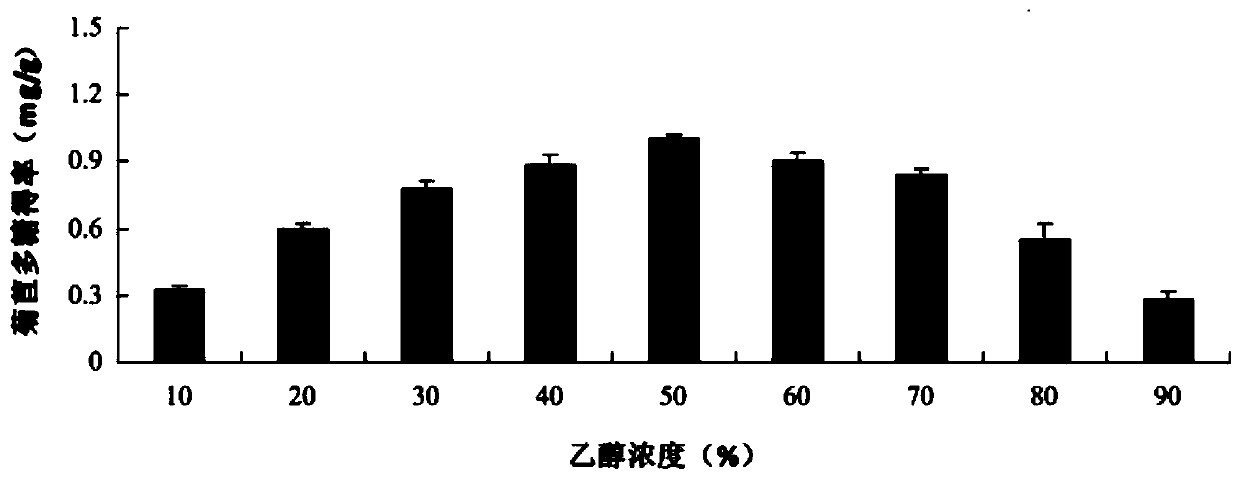

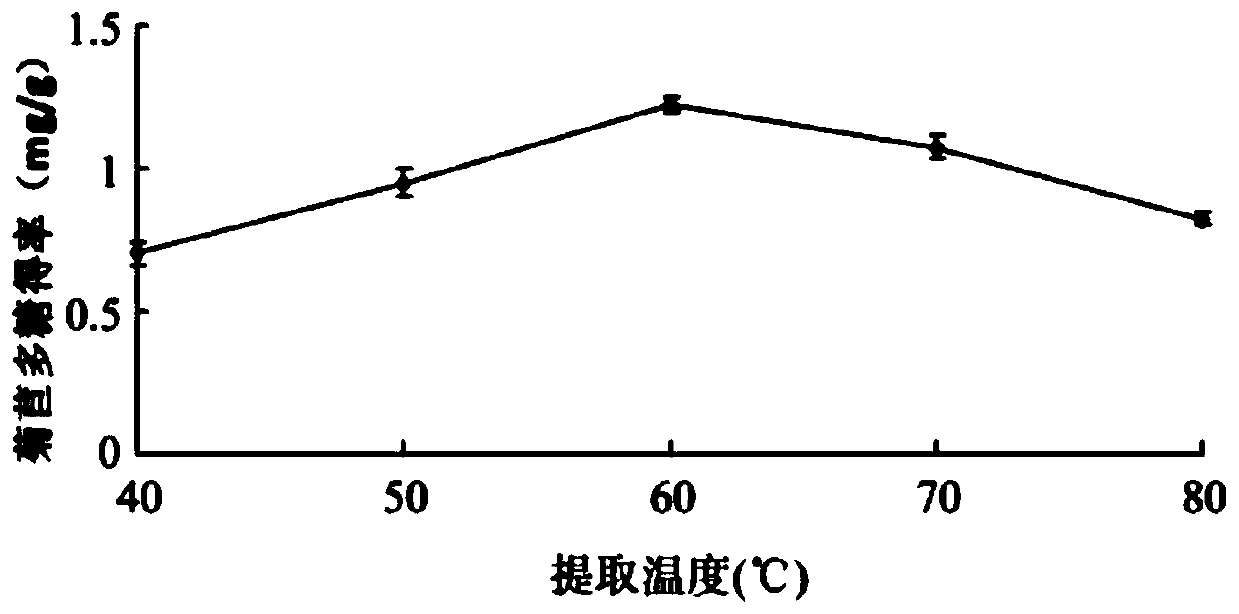

[0034] This embodiment provides an extraction process of chicory polysaccharide. Proceed as follows:

[0035] Step 1: Select chicory roots, use 55% ethanol solution as extraction solvent, temperature 62°C, and material-liquid ratio 1:20.

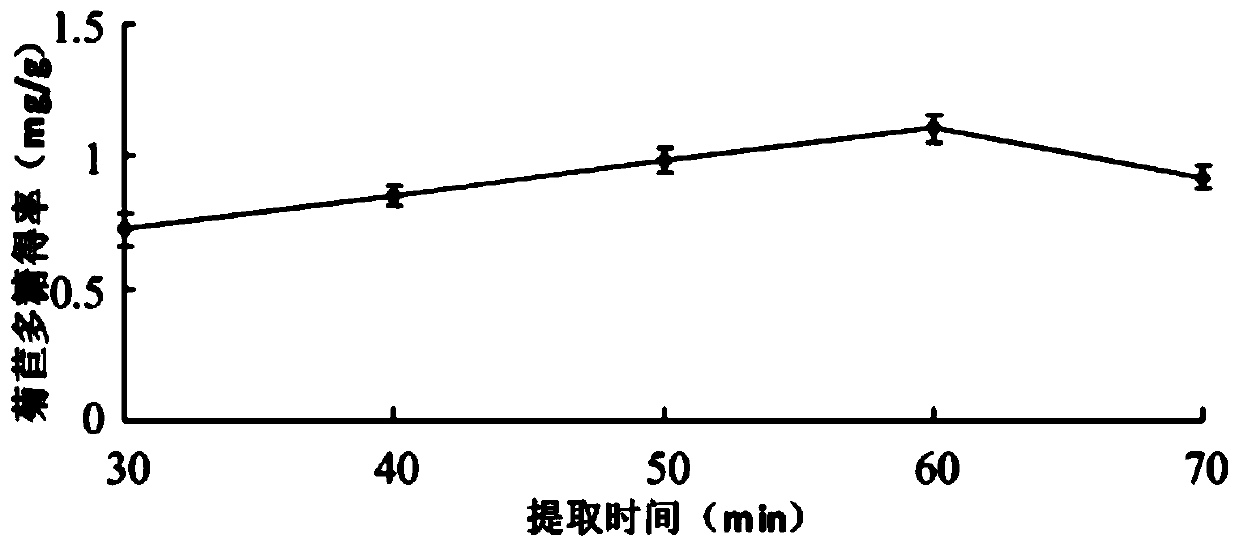

[0036] Step 2: The alcohol extract in step 1 is extracted with ultrasonic assistance, the ultrasonic power is 160W, the extraction times are 2 times, and each time is 0.5h minutes.

[0037] Step 3: Perform ultrafiltration of the extract in step 2. The ultrafiltration membrane used for ultrafiltration is polycarbonate to obtain chicory polysaccharide; the ultrafiltration temperature is 46-55°C, the time is 8-15 minutes, and the flow rate is 40-60ml / min, the pressure is 130-160KPa.

Embodiment 2

[0039] This embodiment provides an extraction process of chicory polysaccharide. Proceed as follows:

[0040] Step 1: Select chicory root, use 60% ethanol solution as extraction solvent, temperature 68°C, and material-liquid ratio 1:10.

[0041] Step 2: The alcohol extract in step 1 is extracted with ultrasonic assistance, the ultrasonic power is 175W, the extraction times are 3 times, and each time is 1 h minutes.

[0042] Step 3: Perform ultrafiltration of the extract in step 2, and the ultrafiltration membrane used for ultrafiltration is polyvinylidene fluoride to obtain chicory polysaccharide; the ultrafiltration temperature is 49° C., time is 12 minutes, flow rate is 50 ml / min, and pressure is 130 KPa.

Embodiment 3

[0044] This embodiment provides an extraction process of chicory polysaccharide. The process steps are as follows:

[0045] Step 1: Choose chicory root, use 80% ethanol solution as extraction solvent, temperature 70°C, and material-liquid ratio 1:25.

[0046] Step 2: The alcohol extract in step 1 is extracted with ultrasonic assistance, the ultrasonic power is 200W, the extraction times are 5 times, and each time is 1.5h minutes.

[0047] Step 3: Perform ultrafiltration of the extract in step 2, and the ultrafiltration membrane used for ultrafiltration is cellulose acetate to obtain chicory polysaccharide; the ultrafiltration temperature is 55° C., time is 15 minutes, flow rate is 60 ml / min, and pressure is 160 KPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com