A kind of air-activated composite material and its application

A composite material and air activation technology, which is applied in the direction of combustion air/combustion-air treatment, charging system, internal combustion piston engine, etc., can solve the problems that the energy saving and emission reduction effect of the air activator is not significant enough, and the emission reduction effect is limited. Good for activation, good energy saving and emission reduction, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] An air-activated composite material, comprising the following components by weight percentage: 40wt% of rare earth composite anion far-infrared functional material, 50wt% of carrier, 5wt% of medical stone with a particle size of 5-10μm, and warp stone with a particle size of 5-10μm Silane coupling agent mica powder 5wt%;

[0027] Wherein, the rare earth composite negative ion far-infrared functional material includes the following components by weight percentage: 10 wt% of lanthanide rare earth oxide, 82 wt% of tourmaline powder with a particle size of 800-12500 mesh and 8 wt% of graphene; the carrier is rubber.

[0028] Combining lanthanide rare earth oxides, tourmaline powder and graphene can promote the release of negative oxygen ions and infrared rays in the air and activate the air efficiently.

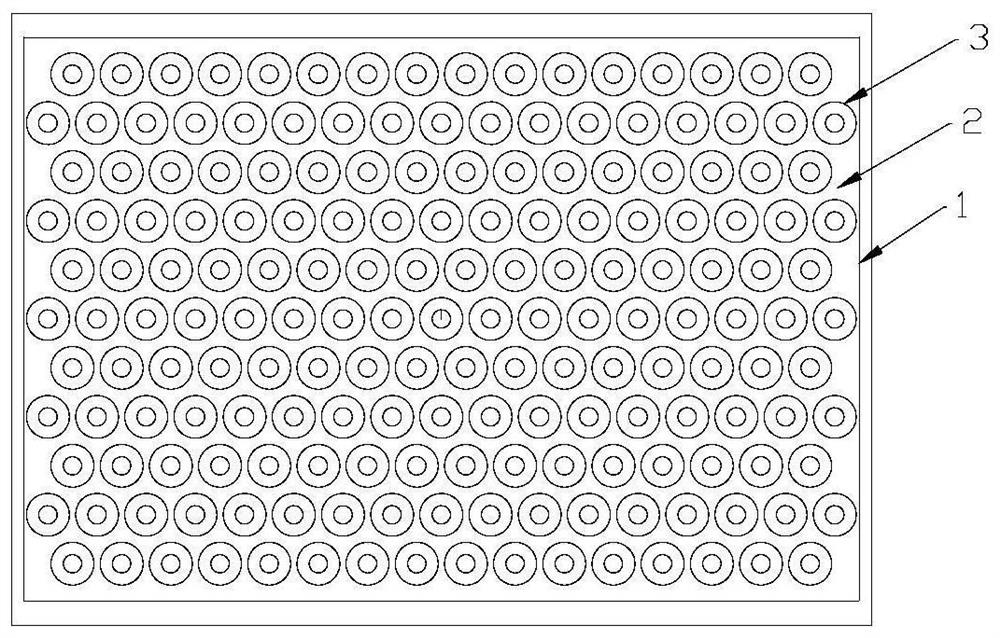

[0029] The air-activated composite material of the present embodiment is processed into a rectangular plate body with a thickness of 10 mm, which is used as a pre-treatmen...

Embodiment 2

[0032] An air-activated composite material, comprising the following components by weight percentage: 40wt% of rare earth composite anion far-infrared functional material, 50wt% of carrier, 5wt% of medical stone with a particle size of 5-10μm, and warp stone with a particle size of 5-10μm Silane coupling agent mica powder 5wt%;

[0033] Wherein, the rare earth composite negative ion far-infrared functional material includes the following components by weight percentage: 15 wt% of lanthanide rare earth oxide, 73 wt% of tourmaline powder with a particle size of 800-12500 mesh and 12 wt% of graphene; the carrier is rubber.

[0034] The air-activated composite material of the present embodiment is processed into a rectangular plate body with a thickness of 10 mm, which is used as a pre-treatment device for energy saving and emission reduction of automobiles (such as figure 1 Shown), installed between the car air intake pipe and the engine combustion chamber. The air enters from t...

Embodiment 3

[0037] An air-activated composite material, comprising the following components by weight percentage: 40wt% of rare earth composite anion far-infrared functional material, 50wt% of carrier, 5wt% of medical stone with a particle size of 5-10μm, and warp stone with a particle size of 5-10μm Silane coupling agent mica powder 5wt%;

[0038] Wherein, the rare earth composite negative ion far-infrared functional material includes the following components by weight percentage: 2 wt% of lanthanide rare earth oxide, 82 wt% of tourmaline powder with a particle size of 800-12500 mesh and 8 wt% of graphene; the carrier is rubber.

[0039] The air-activated composite material of the present embodiment is processed into a rectangular plate body with a 10mm thick band vent, as a pre-treatment device for automobile energy saving and emission reduction (such as figure 1Shown), installed between the car air intake pipe and the engine combustion chamber. The air enters from the air intake surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com