Halogen-free thermoplastic elastomer insulating material and preparation method thereof

A thermoplastic elastomer and insulating material technology, which is applied in the field of cable materials, can solve the problems of low temperature resistance, poor oil resistance, and non-environmental protection, and achieve good flame retardant effect, improved mechanical properties, and good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] Embodiments 1-6 disclose a preparation method of a halogen-free thermoplastic elastomer cable material, comprising the following steps:

[0049] (1) Fill the styrene-based thermoplastic elastomer with filler oil and let it stand for 15-20 minutes;

[0050] (2) Combine the styrene-based thermoplastic elastomer filled with oil in step (1) with polypropylene resin, compatibilizer, extender oil, toughening agent, ethylene-propylene rubber, halogen-free flame retardant, antioxidant, anti-oxidant Add the copper agent and lubricant into the high-speed mixer for mixing;

[0051] (3) adding the mixture obtained in step (2) to a banbury mixer;

[0052] (4) Feed the mixture mixed in the step (3) into a twin-screw extruder and cut it into pellets at 160-200° C. to obtain the halogen-free thermoplastic elastomer insulating material.

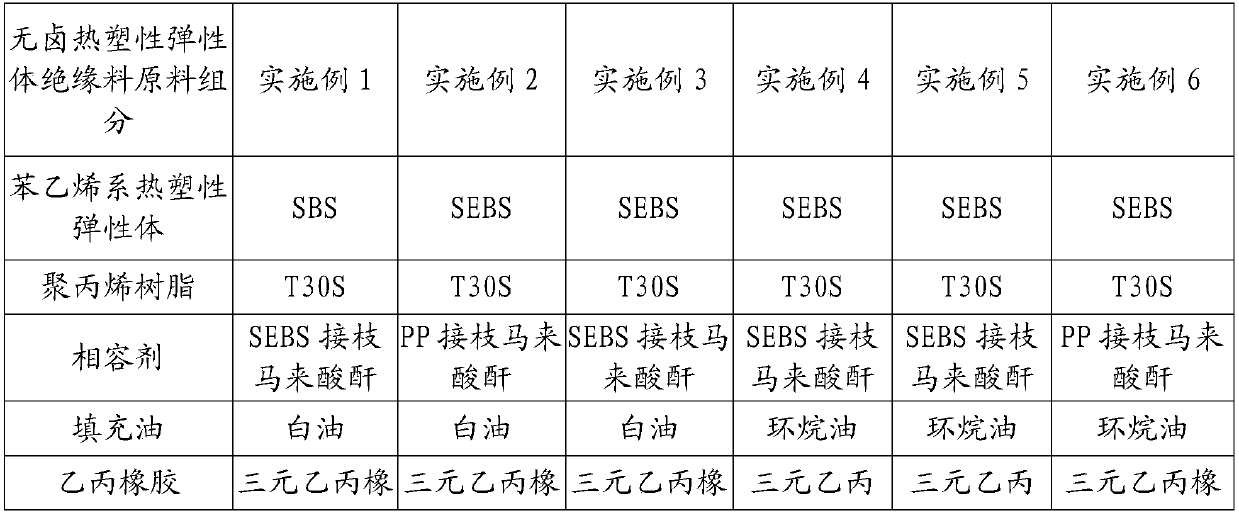

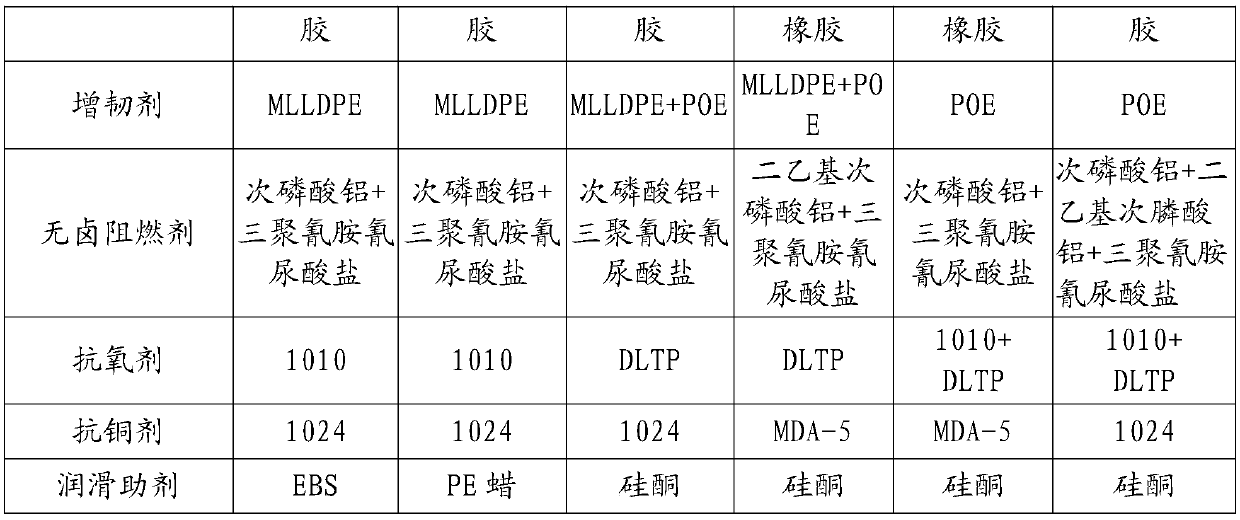

[0053] The raw material components of Examples 1-6 are shown in Table 1.

[0054] See Table 2 for the parts by weight of the raw material component...

Embodiment 7

[0060] Embodiment 7: The products obtained in Examples 1-6 were tested for performance, and the results are shown in Table 3.

[0061] Table 3: Performance testing results of Examples 1-6

[0062]

[0063] It can be seen from Table 3 that using hydrogenated SEBS as the base material has better performance than SBS base material in all aspects, using SEBS grafted maleic anhydride as compatibilizer, the overall performance improvement is more obvious; using metallocene polyolefin resin and poly The compound use of olefin elastomer is helpful to the tear resistance and elasticity of the material. Using non-PPO system, the processing temperature is low and the flame retardant level can also reach V0 level.

[0064] In summary, the halogen-free thermoplastic elastomer insulating material prepared by the present invention has excellent insulation and mechanical properties, low density, low hardness, and good scratch resistance; tensile strength and elongation at break are better ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com