Self-tempering full-bainite structure plastic die steel and preparation method thereof

A technology of plastic mold steel and bainite, applied in the field of iron and steel, can solve the problems of low production efficiency, high manufacturing cost of plastic mold steel, inapplicability, etc., and achieve the effects of low cost, reduced process and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The design composition of the plastic mold steel with full bainitic structure in this embodiment is: C: 0.27%, Si: 0.43%, Mn: 0.79%, Cr: 1.62%, Mo: 0.19%, Ti: 0.025%. , B: 0.0017%, Alt: 0.032%, S: 0.0017%, P: 0.0013%, H: 0.00024%, N: 0.004%, and the rest are Fe and unavoidable impurities.

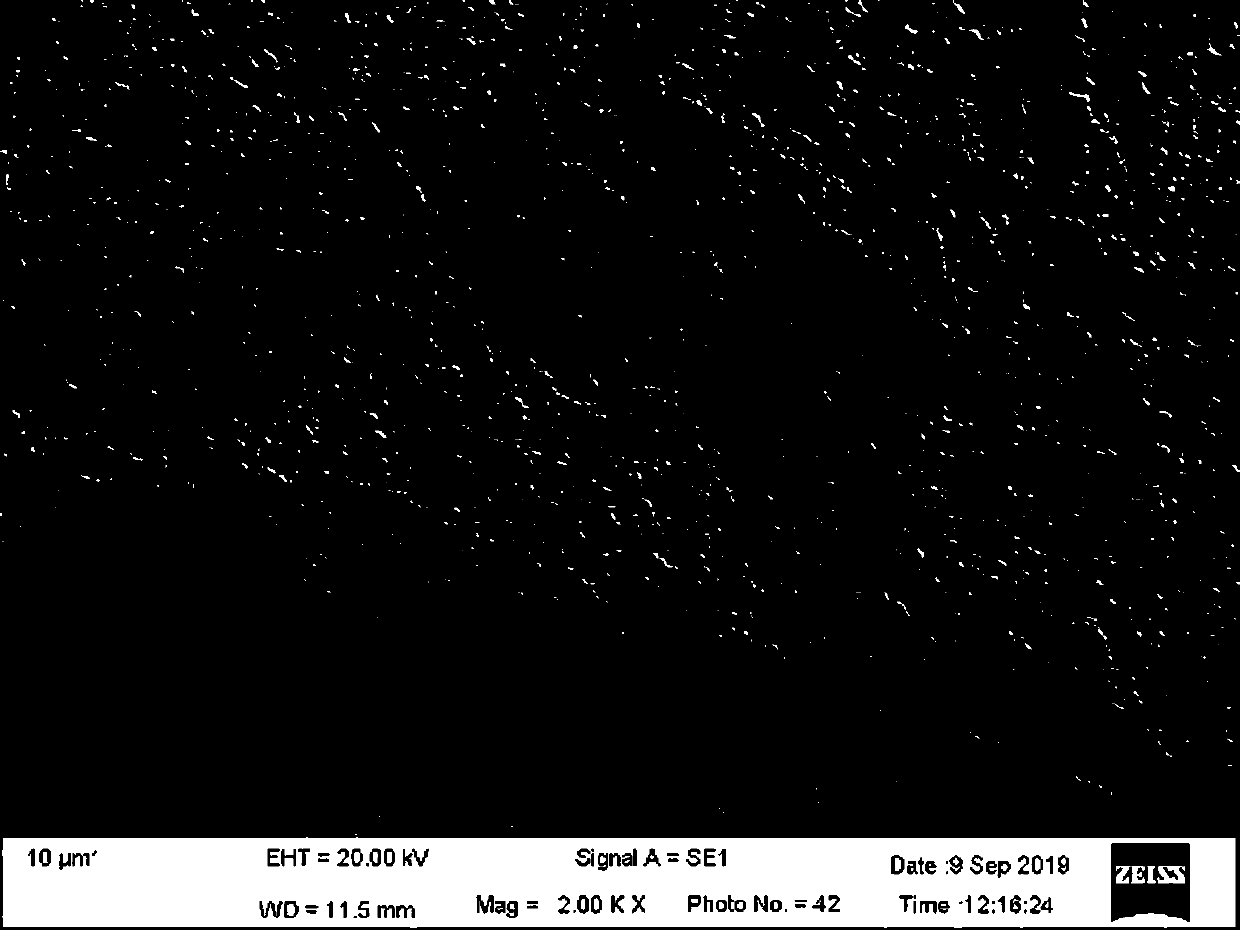

[0038] According to the above ingredients, it is smelted in a converter, continuously cast into a billet of 220*1600mm, and heated in a heating furnace at a heating temperature of 1220°C; it is rolled by a hot rolling process with a starting temperature of 1120°C and a single-pass reduction of 12%. The thickness of the steel plate is 31mm, and the final rolling temperature is 880°C; the hot-rolled steel plate is air-cooled to 350°C on the surface, and then stacked and slowly cooled for more than 48 hours. The steel plate with a final hardness range of 32-34HRC has a microstructure of full bainite organization, see figure 1 and figure 2 shown.

Embodiment 2

[0040] The design composition of the plastic mold steel with full bainitic structure in this embodiment is: C: 0.29%, Si: 0.44%, Mn: 0.79%, Cr: 1.64%, Mo: 0.20%, Ti: 0.020% , B: 0.0017%, Alt: 0.035%, S: 0.001%, P: 0.0015%, H: 0.00021%, N: 0.0032%, and the rest are Fe and unavoidable impurities.

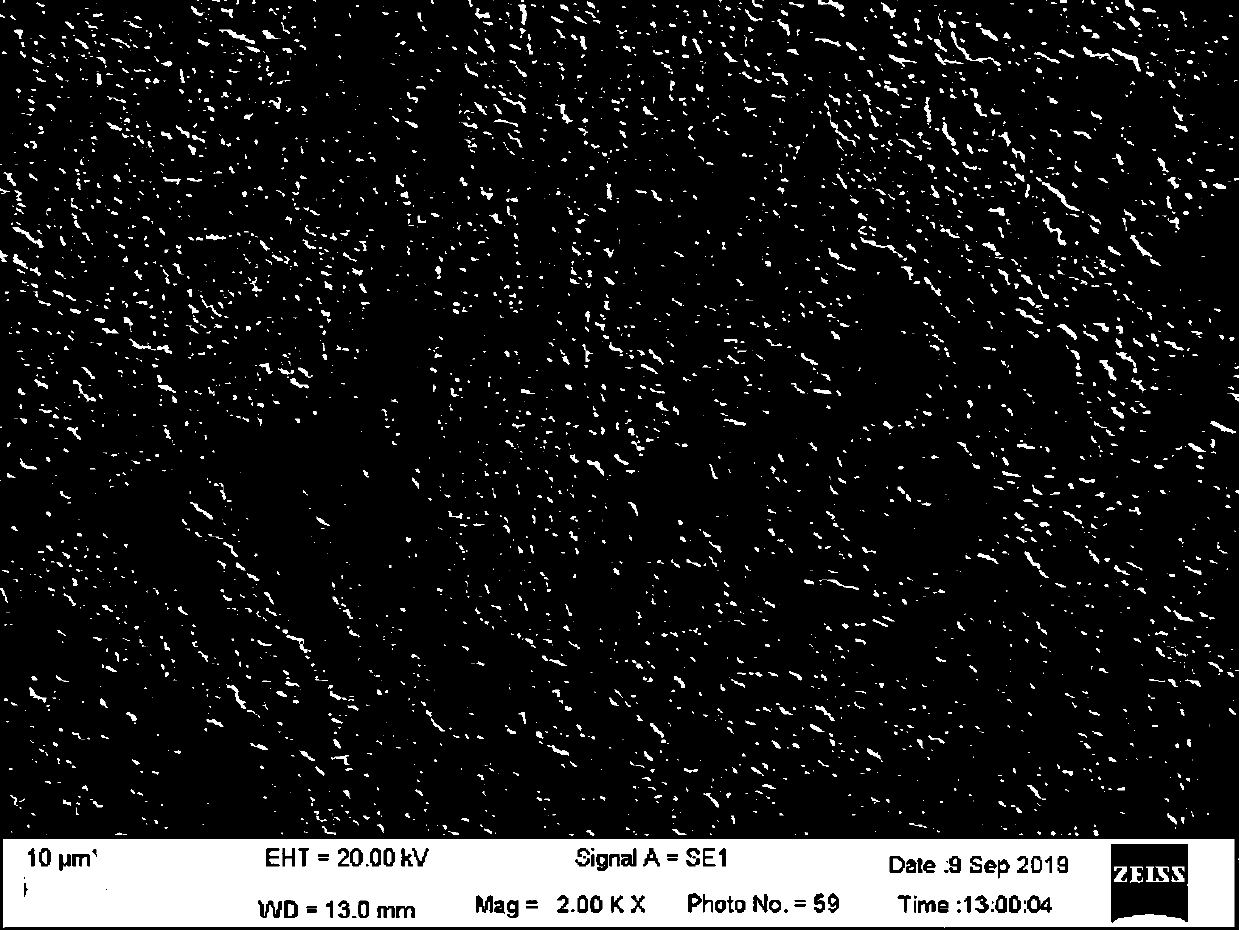

[0041]According to the above composition, it is smelted in a converter, cast continuously into a billet of 220*1600mm, and heated in a heating furnace at a heating temperature of 1240°C; it is rolled by a hot rolling process, with a starting temperature of 1180°C and a single-pass reduction of 11%. The thickness of the steel plate is 46mm, and the final rolling temperature is 860°C; after the hot-rolled steel plate is air-cooled to a surface temperature of 450°C, and then stacked and slowly cooled for more than 48 hours, the steel plate with a final hardness range of 30-32HRC has a microstructure of full shell body structure, see image 3 and Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com