Digital fuel system

A fuel system, digital technology, applied in the direction of charging system, turbine/propulsion fuel delivery system, gas turbine device, etc., can solve the problems that are not conducive to the stable operation of the gas generator and cannot guarantee the stable state of the gas generator, and achieve The effect of expanding the range of use, light weight and superior function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

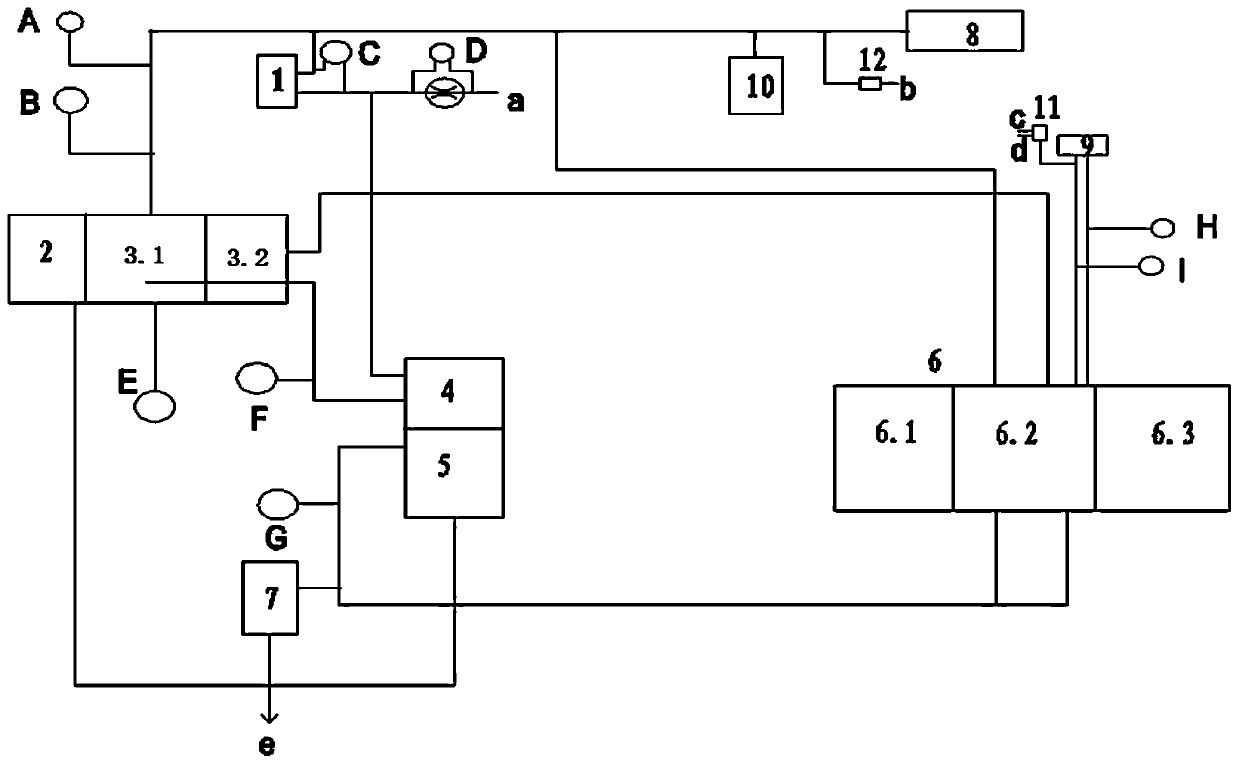

[0019] The present invention will be further described in detail below in conjunction with the drawings.

[0020] See figure 1 , The digital fuel system of the present invention includes a gear pump 3.1, the input end pipeline of the gear pump 3.1 is connected to the fuel inlet a, the running power of the gear pump 3.1 is provided by the motor 2, and the pipeline between the gear pump 3 and the fuel inlet a A flow meter D is provided, and the flow meter D is used to measure the flow rate of the input fuel. A fuel filter 1 is installed on the pipeline between the gear pump 3 and the flow meter D. The input end and the output end of the fuel filter 1 are connected to a differential pressure signal C. The differential pressure signal C is used to measure fuel filtration The pressure difference before and after. The output pipe of the fuel filter 1 after the contact C of the differential pressure signal is divided into two paths, one is connected to the gear pump 3.1, the other is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com