Method and system for safely destroying and recycling waste ammunition through ultrahigh-pressure water jet

An ultra-high pressure, water jet technology, applied in the security field, can solve the problems of inconvenient destruction of used ammunition, safety risks, and a large number of blasting sites, and achieve the effects of safe and reliable use, improved safety, and resource conservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

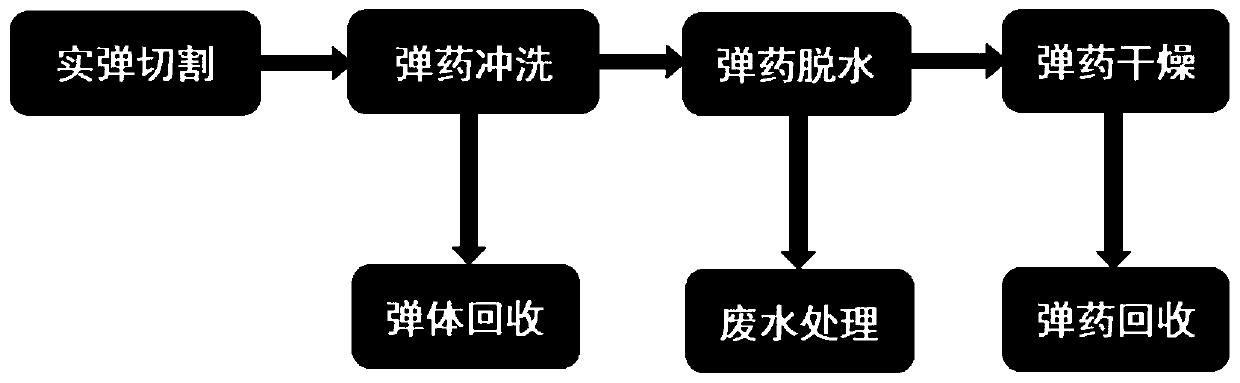

[0033] Such as figure 1 shown.

[0034] A method for safe destruction and recycling of waste ammunition by ultra-high pressure water jets, comprising the following steps:

[0035] First, set up an explosion-proof safety area, and install water cutting equipment, high-pressure washing equipment and ammunition clamping equipment in the explosion-proof area; the explosion-proof area can be an explosion-proof workshop or an area with an explosion-proof cofferdam;

[0036] Secondly, the ammunition to be destroyed is clamped on the ammunition clamping device by manual or automatic clamping technology, and the ammunition clamping device drives the ammunition to perform cutting motion according to the set procedure;

[0037] Third, aim the cutting head of the ultra-high pressure water cutting equipment at the ammunition, use the ultra-high pressure water jet to complete the cutting of the ammunition, and keep the explosive storage chamber on the ammunition clamping equipment; cutting...

Embodiment 2

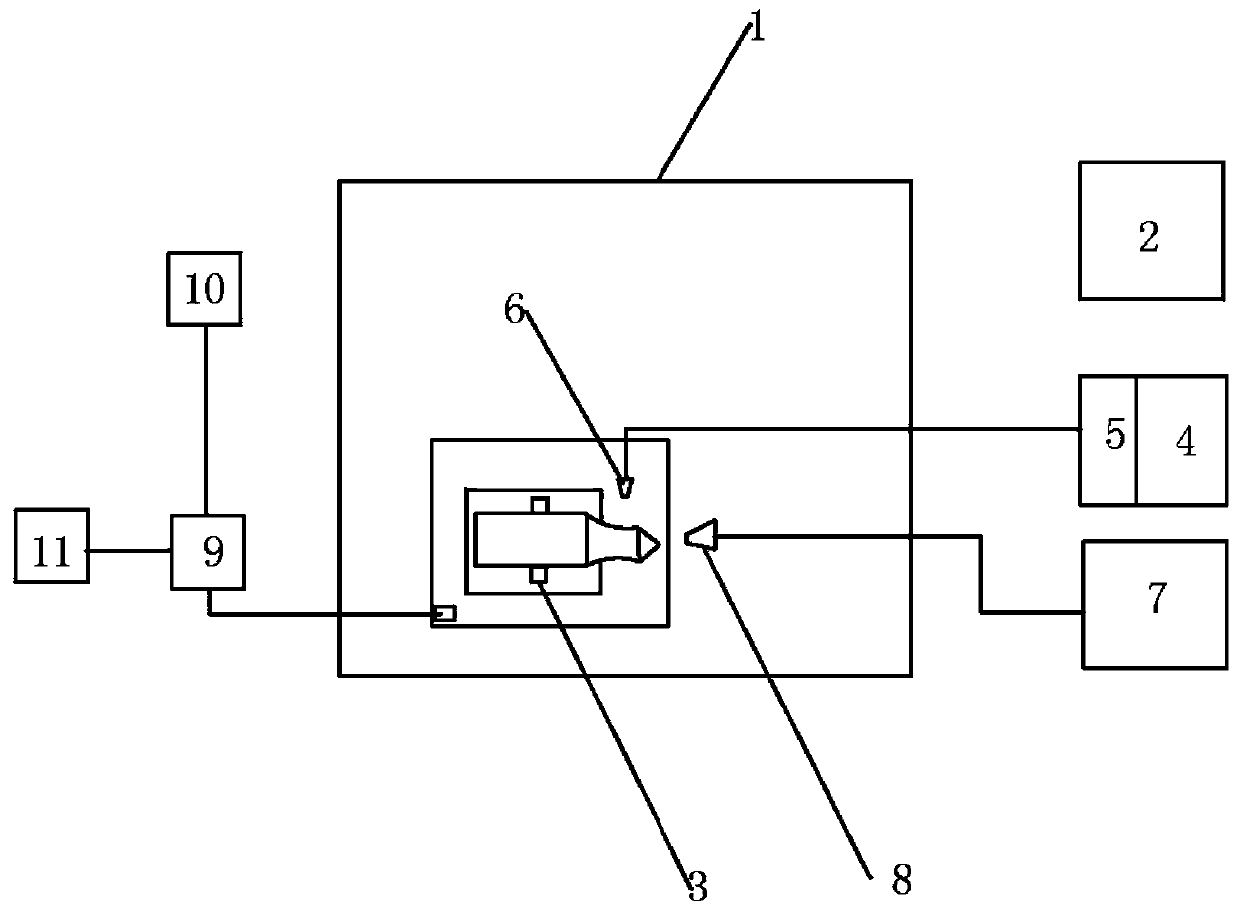

[0050] Such as figure 2 shown.

[0051] An ultra-high pressure water jet safe destruction and recycling system for waste ammunition; it includes:

[0052] An explosion-proof area 1, which is used to install the required ammunition destruction equipment; it can be an explosion-proof workshop, or it can be an open pit or a site with an explosion-proof cofferdam. It is recommended to use an explosion-proof workshop to realize factory operations.

[0053] A control center 2, which is located outside the explosion-proof area and is used to remotely control the operation of the ammunition destruction equipment to ensure the personal safety of the staff; , The operating equipment is introduced into the control center to realize separate remote control;

[0054] An ammunition clamping device 3, the ammunition clamping device is used to clamp the ammunition and can drive it for cutting operation, the ammunition clamping device is fixedly installed in the explosion-proof area, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com