Insulator and quartz boat

A technology of insulators and quartz boats, applied in the field of quartz boats, can solve problems such as limited effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

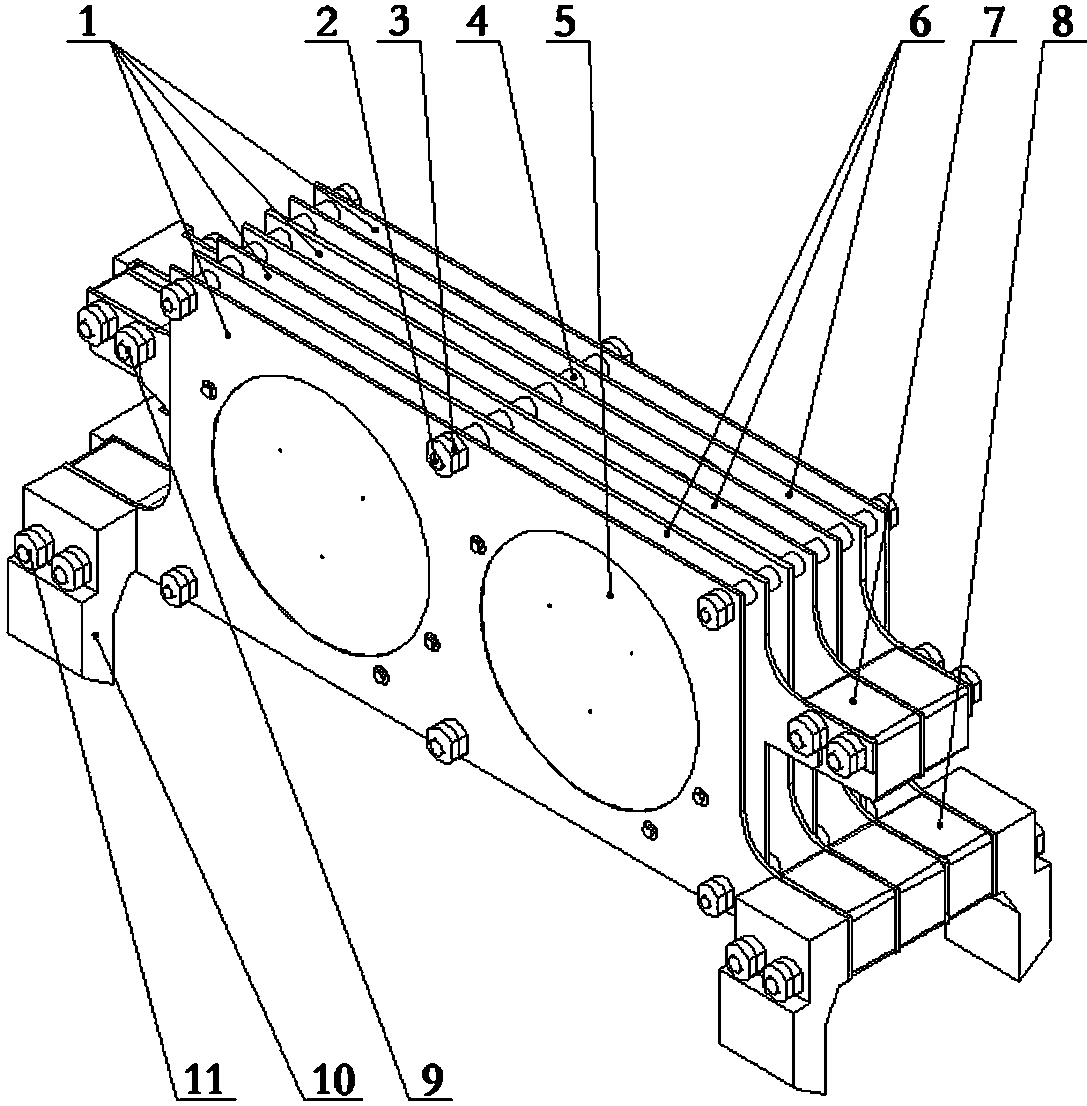

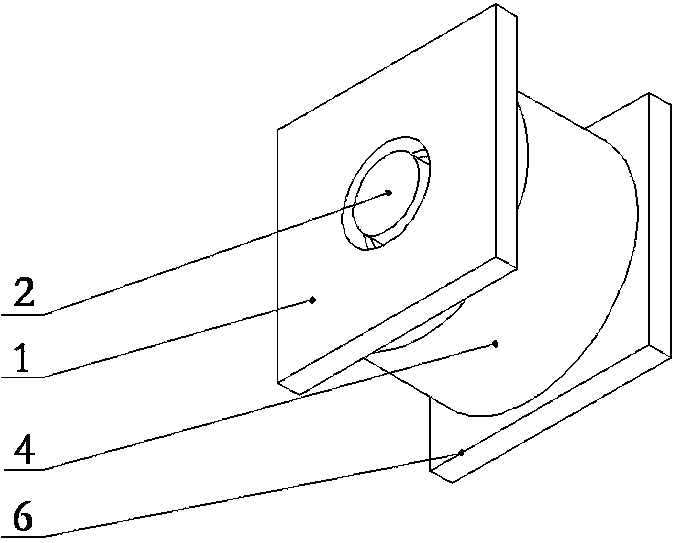

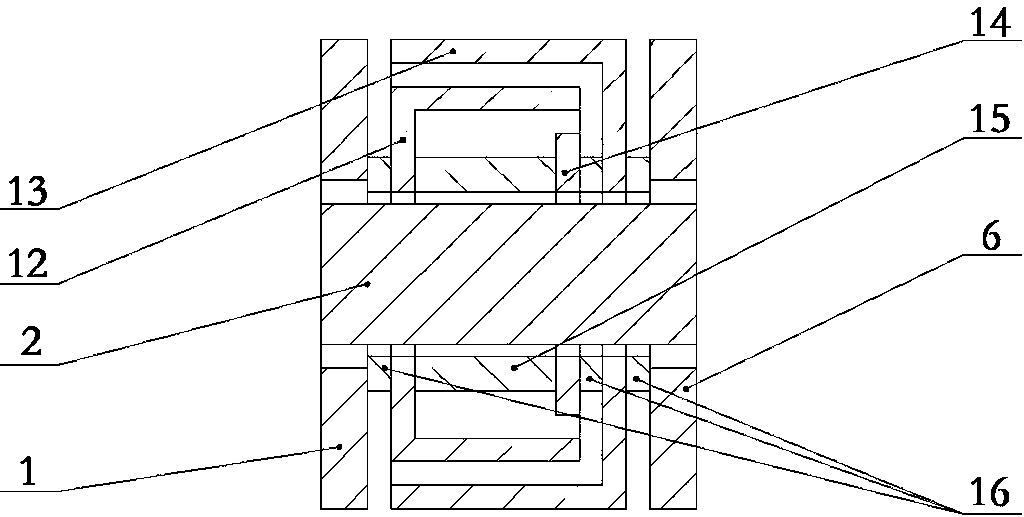

[0034] The insulator 4 used on the quartz boat is generally a sleeve structure, such as figure 1 as shown, figure 1 Among them, seven electrode sheets (also known as electrode plates) are assembled in parallel through six fixed rods 2 and nuts 3. The insulator 4 set on the fixed rod 2 is used for insulation between adjacent electrode sheets, and the insulator The axial length of 4 determines the distance between adjacent electrode plates.

[0035] Generally speaking, the airflow carrying the carbon powder flows through the space between the electrode plates in an advection manner. Regarding the boundary friction effect of Newtonian internal friction, it can also be understood based on conventional life experience. For example, the closer the water flow in a river is to the center line, the faster the water flow speed. On the contrary, the closer to the shore, the slower the water flow speed. For the boundary friction effect produced by the side flow, the side flow produces i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com