Motor driving circuit and method thereof

A motor drive and drive circuit technology, applied in the direction of electrical components, electromechanical devices, electronic commutators, etc., can solve the problems of power consumption of brushless DC motors, low efficiency of brushless DC motors, and increase of feedback current, etc., to achieve Effect of reducing feedback current, reducing power, and eliminating offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

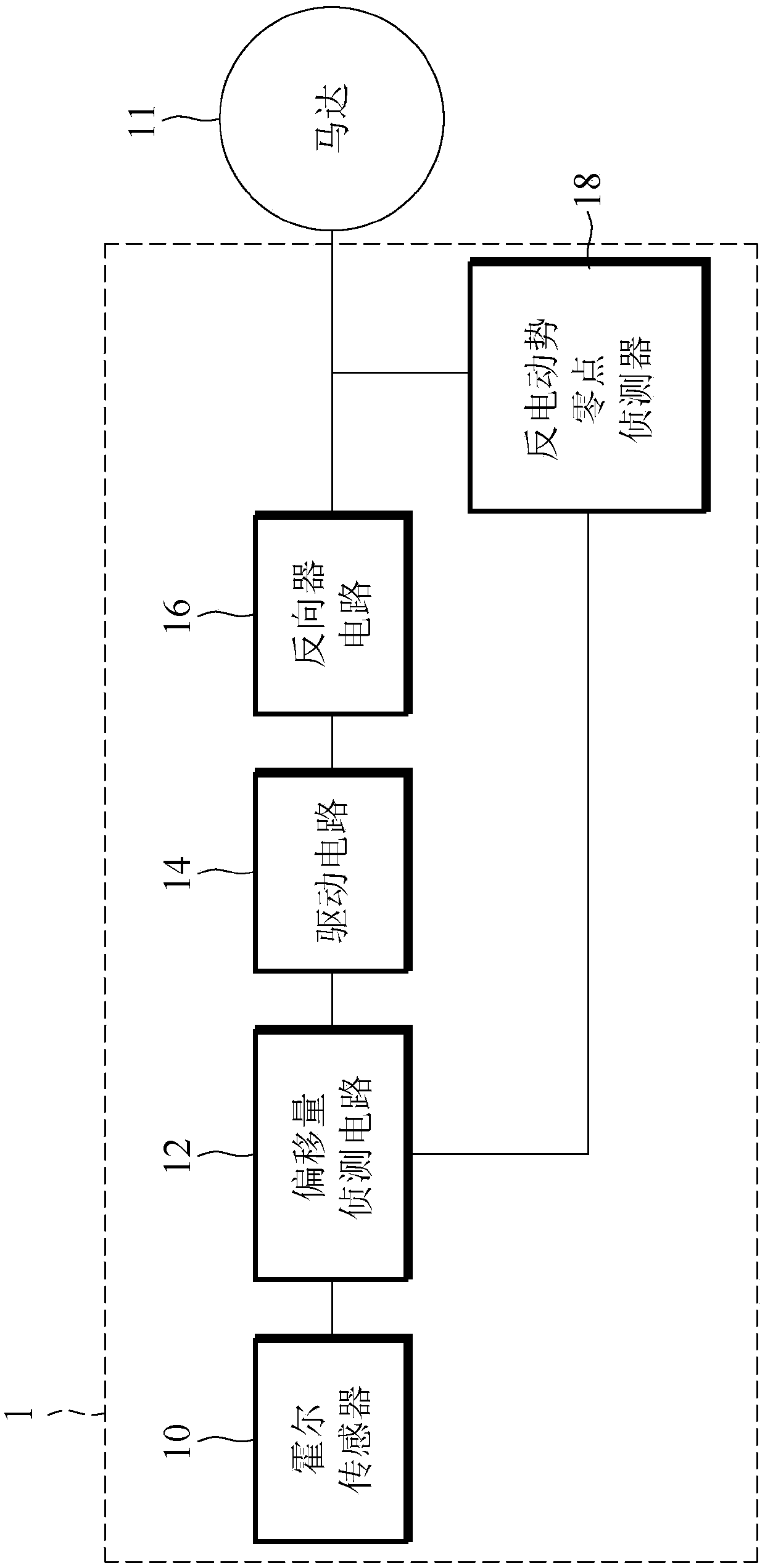

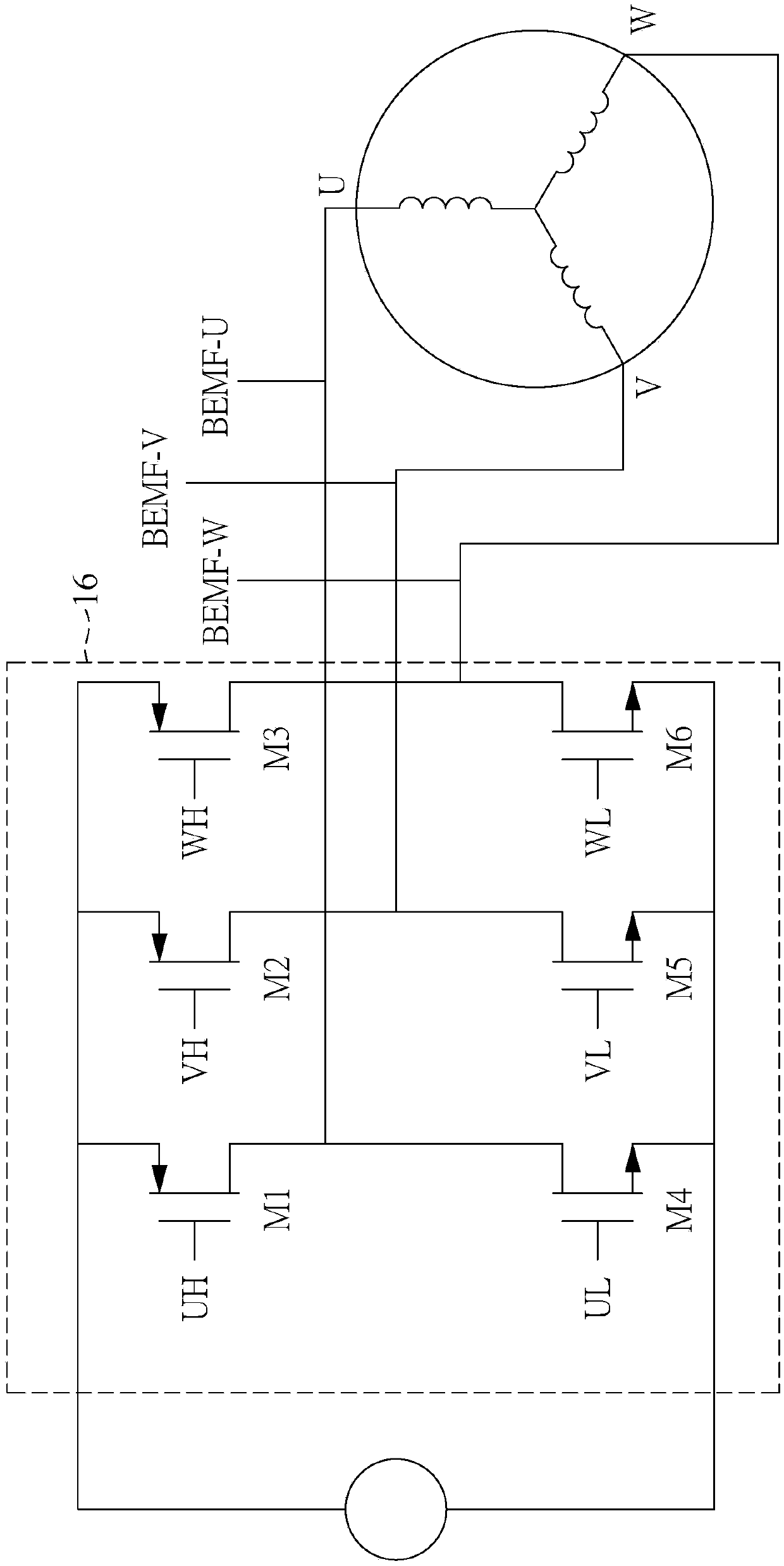

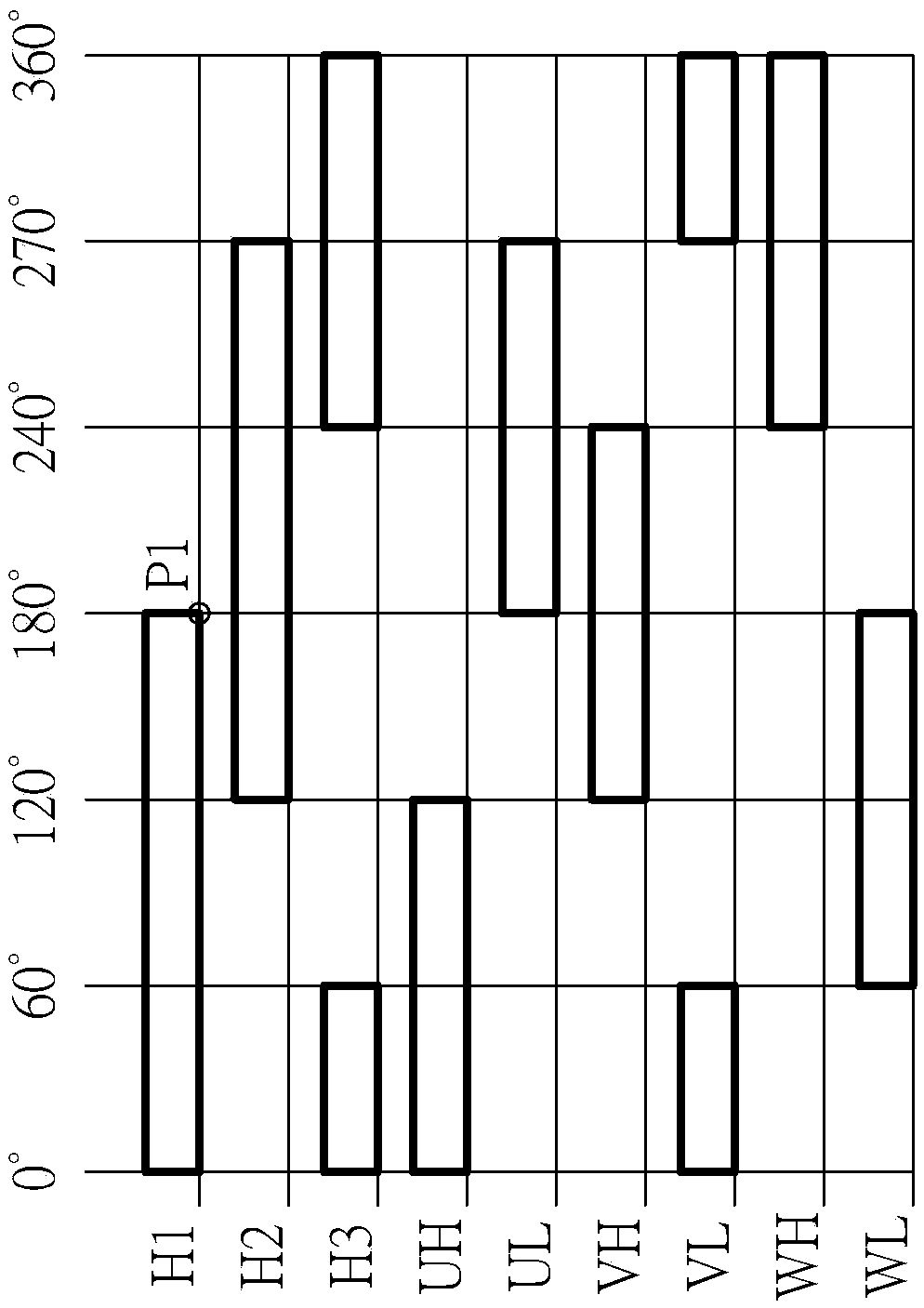

[0028] Please also refer to Figure 1 to Figure 3 , figure 1 It is a circuit structure diagram of the motor driving circuit of the first embodiment of the present invention, figure 2 It is the circuit structure diagram of the three-phase motor and inverter circuit, image 3 Schematic diagram of six-step square wave switching for Hall sensor signal control. refer to figure 1 As shown, the first embodiment of the present invention provides a motor drive circuit 1 for driving a motor 11. The motor drive circuit 1 includes a Hall sensor 10, an offset detection circuit 12, a drive circuit 14, and an inverter circuit. 16 and counter electromotive force zero detector 18.

[0029] The Hall sensor 10 can be arranged adjacent to the motor 11, and is used to sense the change of the magnetic field of the motor 11, and determine the rotor position of the motor 11, so as to generate a Hall signal group accordingly. Taking a three-phase motor as an example, as figure 2 The first Hall ...

no. 2 example

[0051] Please refer to Figure 7 , Figure 7 It is a flow chart of the motor driving method according to the second embodiment of the present invention. The method described in this example can be figure 1 shown in the motor drive circuit 1, so please also follow Figure 1 to Figure 6 To facilitate understanding, the motor driving method includes the following steps:

[0052] Step S100: configure a Hall sensor to detect a rotor position of the motor and generate a Hall signal set. Wherein, depending on whether the motor is a single-phase motor or a three-phase motor, the Hall signal group may have different numbers of Hall signals.

[0053] Step S101: configure the offset detection circuit to receive the Hall signal group and detect the first commutation point of the Hall signal group.

[0054] Step S102: configure the driving circuit to receive the Hall signal group, and generate an initial commutation signal according to the Hall signal group.

[0055] Step S103 : conf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com