Copper colloidal catalyst liquid for electroless copper plating, electroless copper plating method, and production method for copper-plated substrate

A technology of electroless copper plating and manufacturing method, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., and can solve the problems of difficulty in maintaining catalyst continuity for a long time and stability over time, and coating streaks Uniformity and other issues, to achieve the effect of improving stability over time, excellent sustainability, and improved effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0112] In the preparation of the catalyst solution, in order to supply electrons from the reducing agent (B) to the copper ions smoothly, it basically takes time to slowly drop the solution of the reducing agent (B) into the solution containing the soluble copper salt (A) (and the colloidal stabilizer). (C)) solution. For example, drop the solution of reducing agent (B) preferably at 5°C to 50°C, more preferably at 10°C to 40°C, into the solution of soluble copper salt (A), and stir for preferably 20 minutes to 1200 minutes, more preferably For 30 minutes to 300 minutes, a catalyst liquid is prepared. It should be noted that dropping the solution of the soluble copper salt (A) into the solution of the reducing agent (B) is not excluded when preparing the catalyst solution.

[0113] In the catalyst solution of the present invention, the copper colloidal particles generated by the soluble copper salt (A) under the action of the reducing agent (B) have a suitable average particl...

Embodiment

[0150] Hereinafter, examples of the electroless copper plating method comprising the preparation of the liquid containing the adsorption accelerator, the copper colloid catalyst solution, and the electroless copper plating solution of the present invention are described, and the time-dependent stability of the copper colloid catalyst solution is sequentially described. Performance, durability of catalyst activity, and evaluation test examples of the appearance of the copper film obtained in the following examples.

[0151] It should be noted that the present invention is not limited to the following examples and test examples, and it is of course possible to make arbitrary modifications within the scope of the technical concept of the present invention.

[0152] "The Embodiment of Electroless Copper Plating Method"

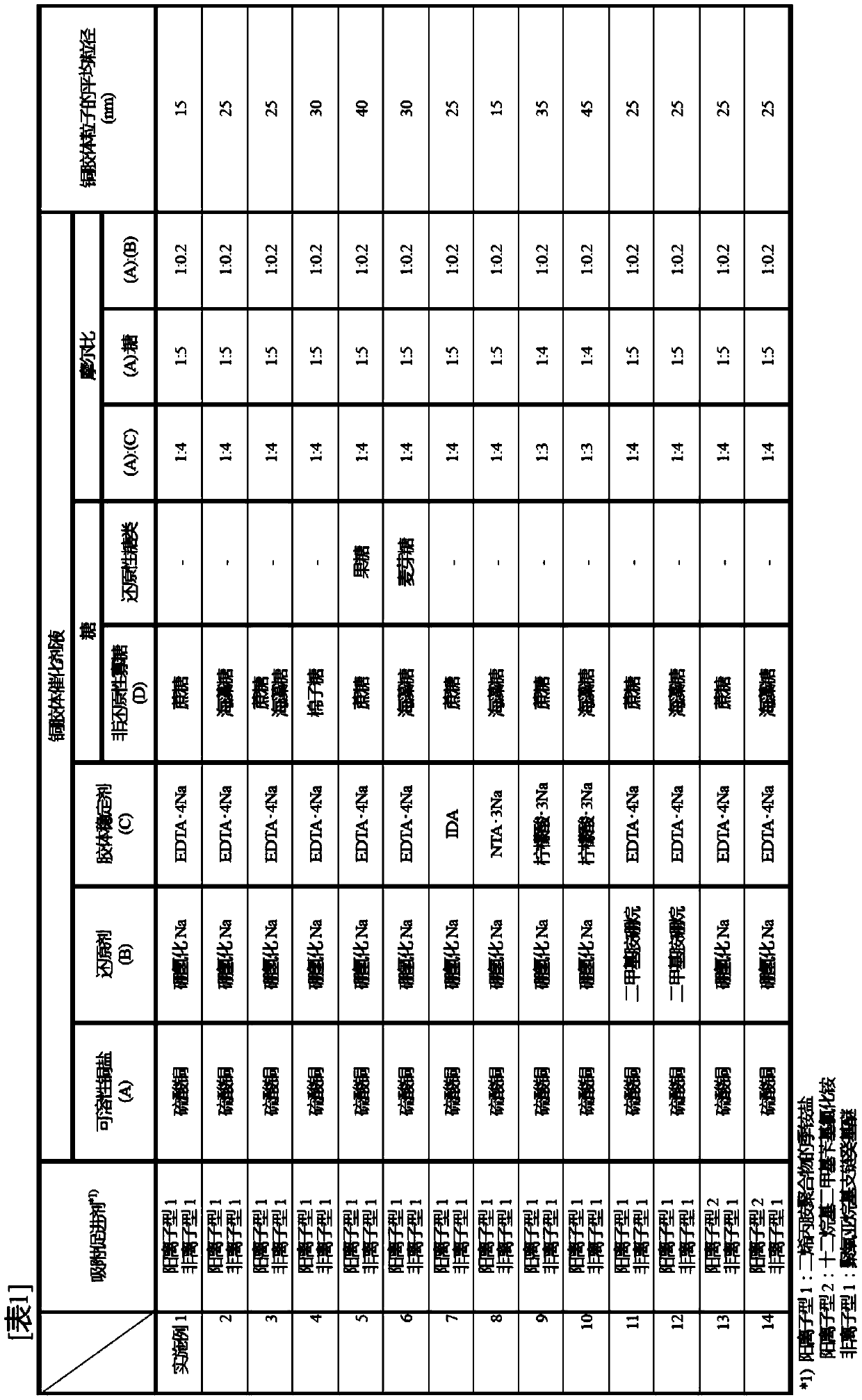

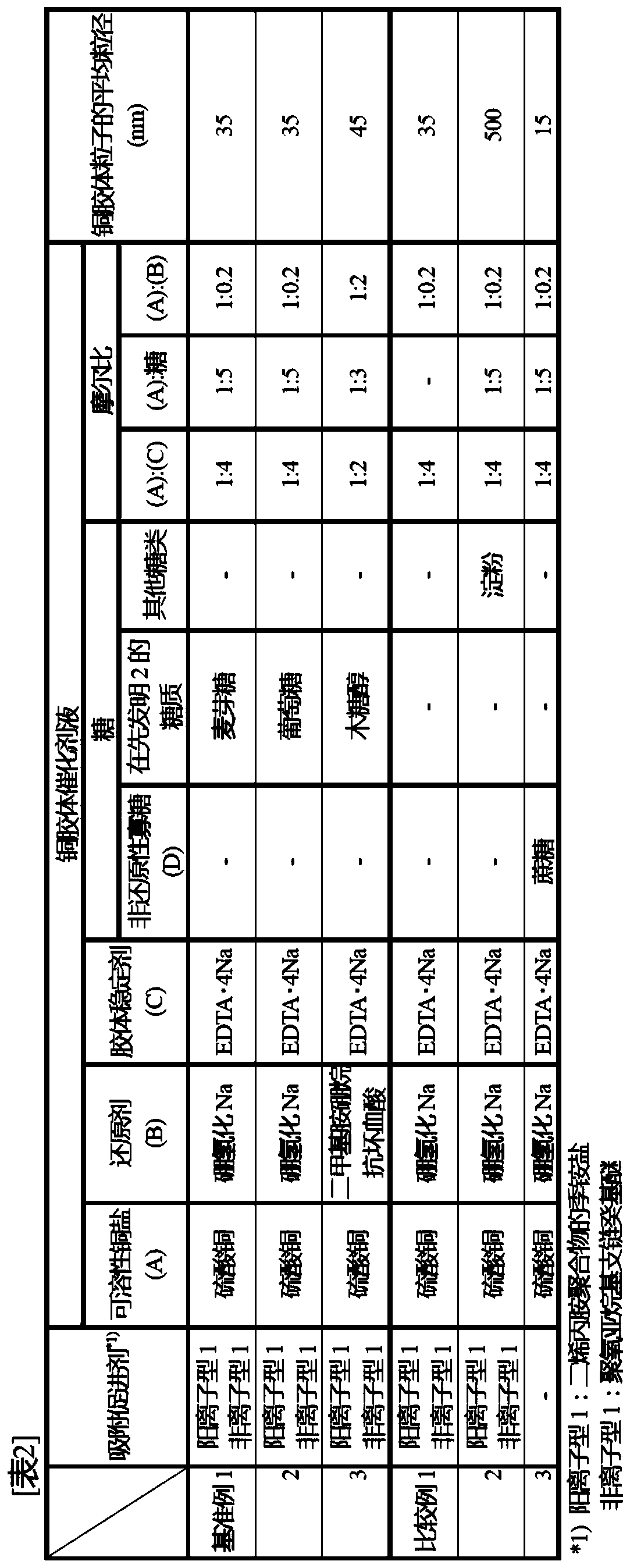

[0153] In the following Examples 1 to 14, the liquid containing the adsorption accelerator and the copper colloidal catalyst liquid in Example 1 contained the fol...

Embodiment 2

[0163] Example 2: Change of non-reducing oligosaccharide (D) to trehalose

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com