Salt coat finishing composition and preparation method and application thereof

A composition and finishing technology, applied in coatings, fire-retardant coatings, etc., can solve problems such as health risks and environmental protection, and achieve the effects of fine texture, easy repair and good decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of salt series finishing material in the present invention, steps are as follows:

[0050] 1) Start the dry powder mixer;

[0051] 2) First put the salt powder and hydroxyethyl cellulose ether of the formula amount into the dry powder mixer, and stir for 2-3min;

[0052] 3) Then put the additives such as starch ether and air-entraining agent in the formula amount into the dry powder mixer, and continue to stir for 2-3min;

[0053] 4) Then put the mixed powder into the mortar mixer, add water equivalent to half of the formula, start the mortar mixer, and stir for 1-2 minutes;

[0054] 5) After standing for 1 minute, put the remaining water into the mortar mixer, continue to stir for 2-4 minutes, and discharge the material to obtain a freshly mixed slurry of the salt-based finishing material.

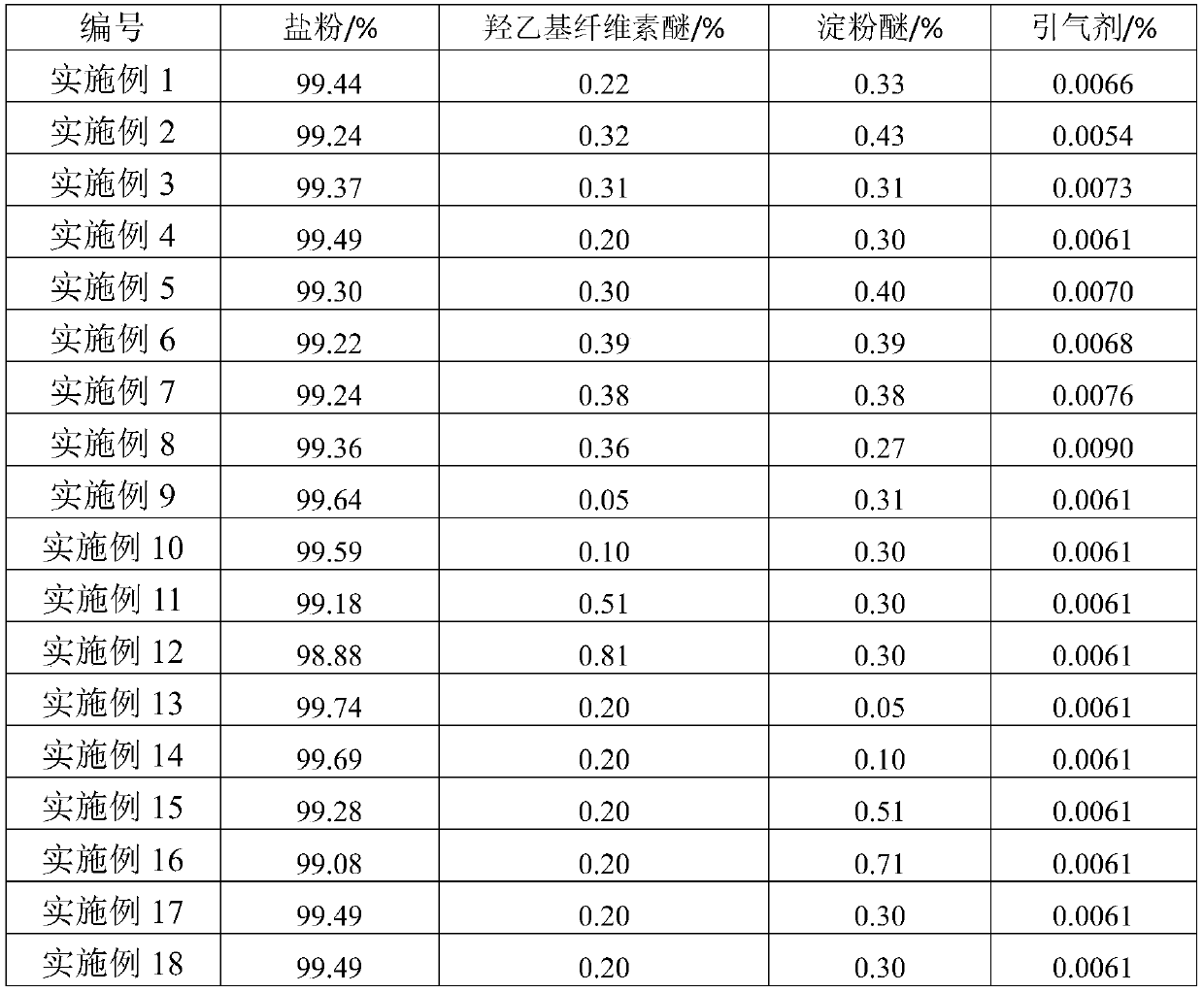

Embodiment 1

[0062] Proportion: 900 parts of salt powder (250-325 mesh), 2 parts of hydroxyethyl cellulose ether, 3 parts of starch ether, 0.06 part of air-entraining agent and 255 parts of water.

Embodiment 2

[0064] Proportion: 920 parts of salt powder (250-325 mesh), 3 parts of hydroxyethyl cellulose ether, 4 parts of starch ether, 0.05 part of air-entraining agent and 260 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brookfield viscosity | aaaaa | aaaaa |

| Brookfield viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com