Distillation and retorting bucket loading material distribution machine for liquor and spirits by solid-state method

A method of liquor and distributor technology, which is applied to the field of upper retort distributor in the distillation of solid-state liquor, can solve the problems of difficulty in bulk density by manual feeding, aggravate the physical consumption of operators, and cannot guarantee the quality of production, etc., so as to improve the economic benefits of enterprises and Competitiveness, reduced food consumption, reduced labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

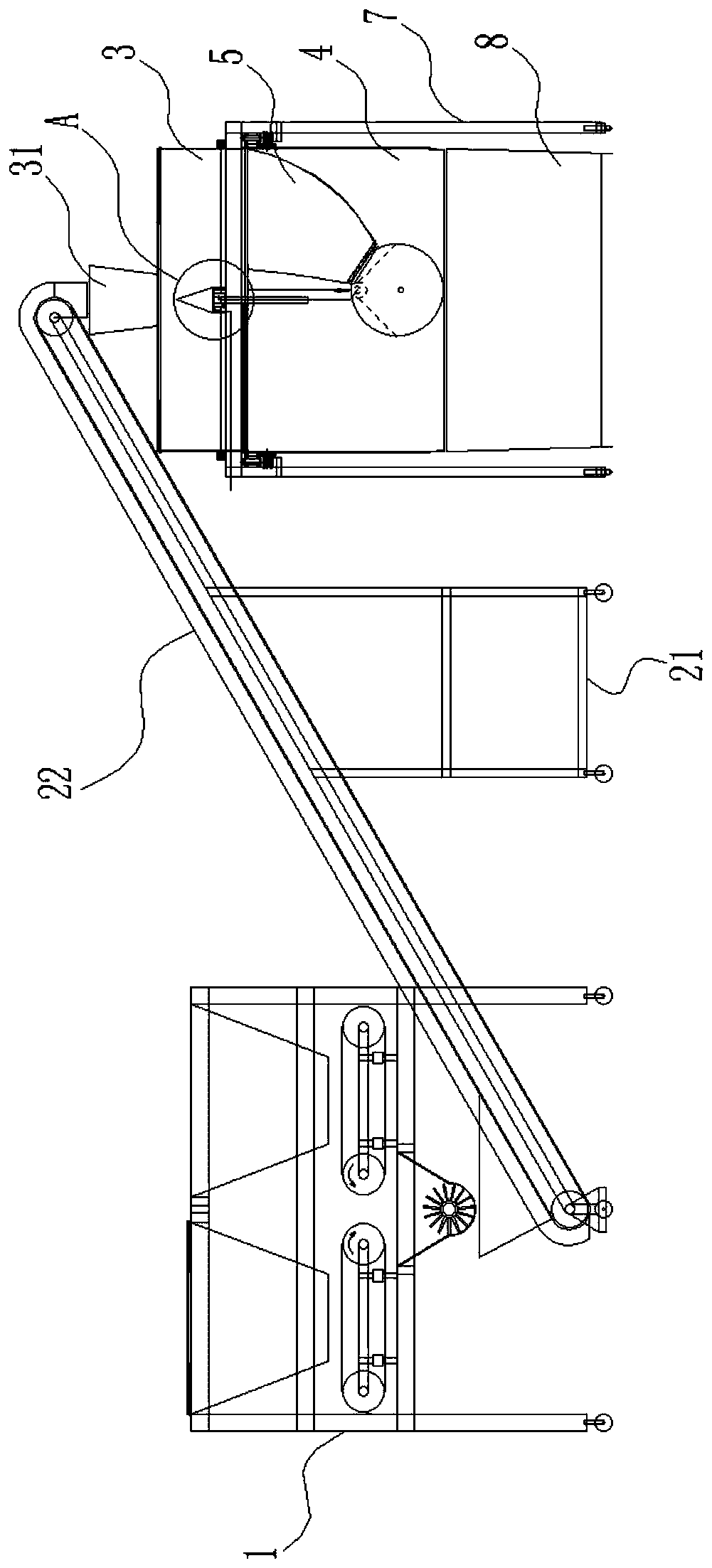

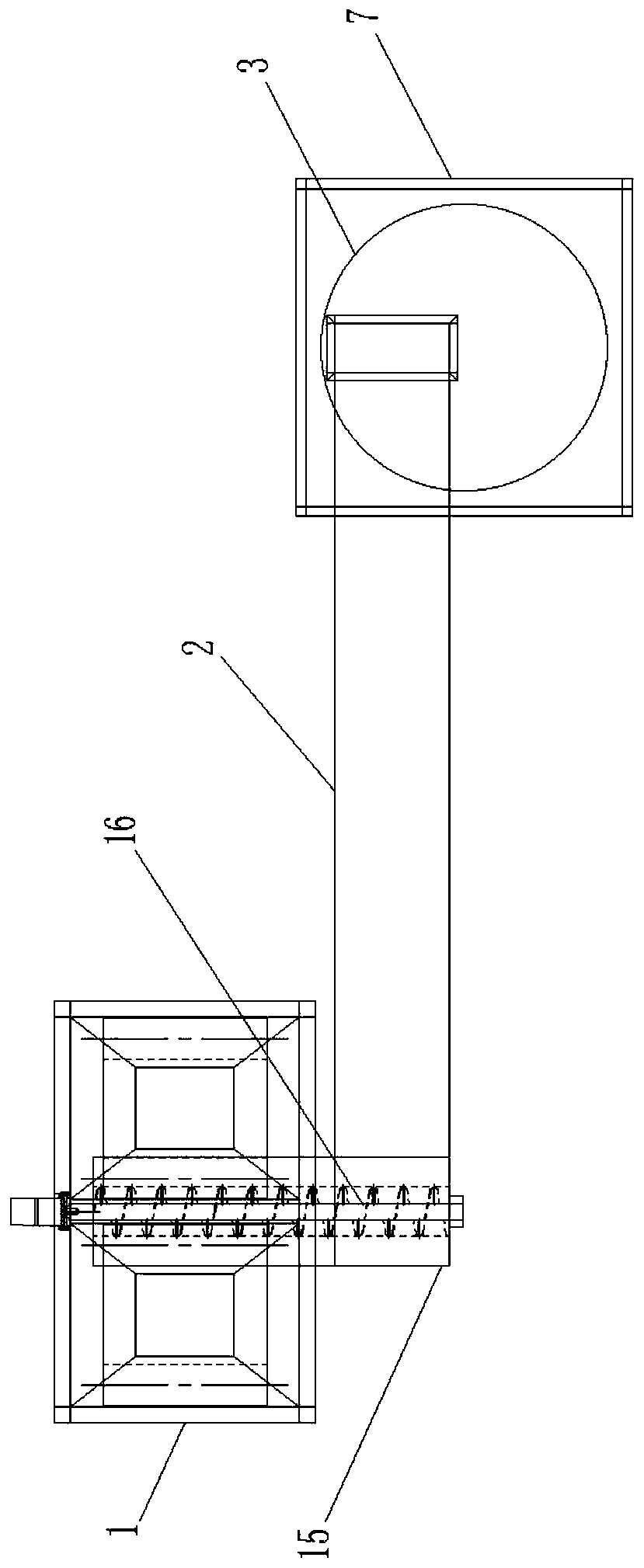

[0045] The specific embodiment of the present invention is as Figure 1-9 As shown, a distributing machine for distributing retorts for solid-state liquor distillation includes a stirring mechanism 1 and a feeding mechanism 2. The discharge end of the feeding mechanism 2 is connected with a cloth mechanism. Through this equipment, the raw materials for wine steaming can be stirred into wine grains, and the wine grains can be evenly distributed layer by layer into the retort barrel.

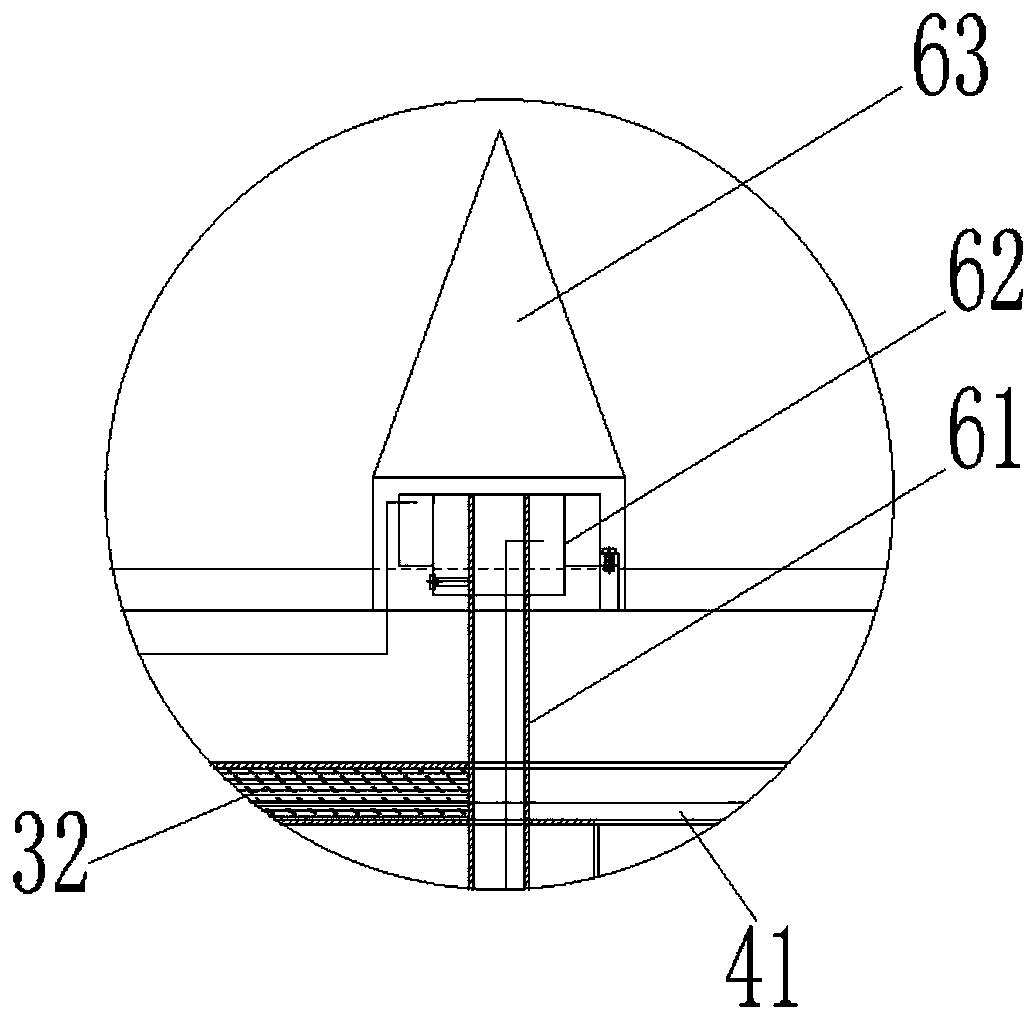

[0046] Wherein, the material distributing mechanism includes an upper material bin 3 connected vertically in sequence and a rotary lower material cylinder 4 capable of axial rotation. Inside the rotating lower material cylinder 4 is provided a material lower chamber 5 arranged around its axis and opening upward. The lower part of the feeding small chamber 5 is provided with a discharge port 53 extending to the axis and edge of the rotating discharge barrel 4 at both ends; the discharge port 53 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com