Full-MOS voltage and temperature monitoring method and circuit

A technology for monitoring circuits and voltages, which is applied in the field of full MOS voltage and temperature monitoring methods and circuits, can solve problems such as poor practicability, high cost, and poor practicability, and achieve improved range and accuracy, no static power consumption, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

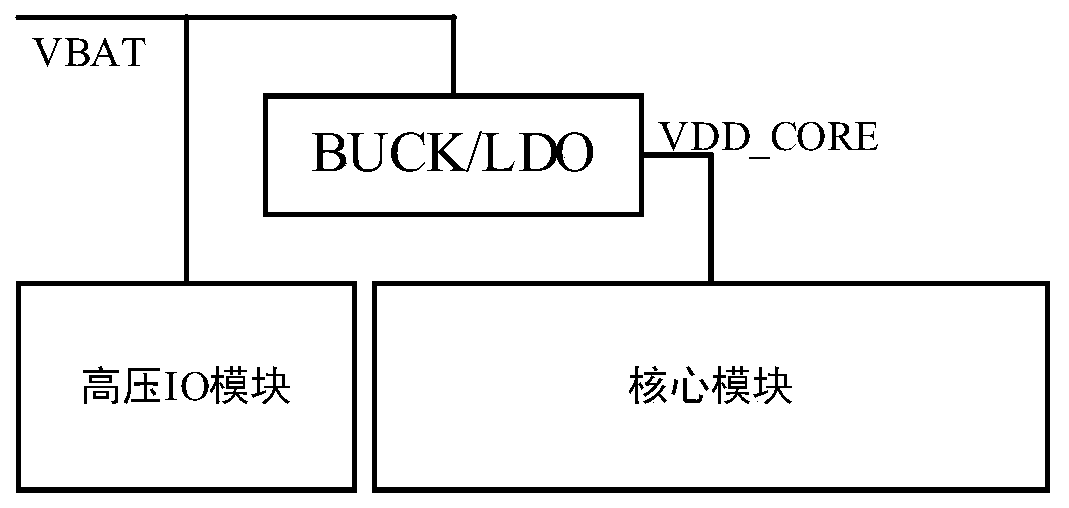

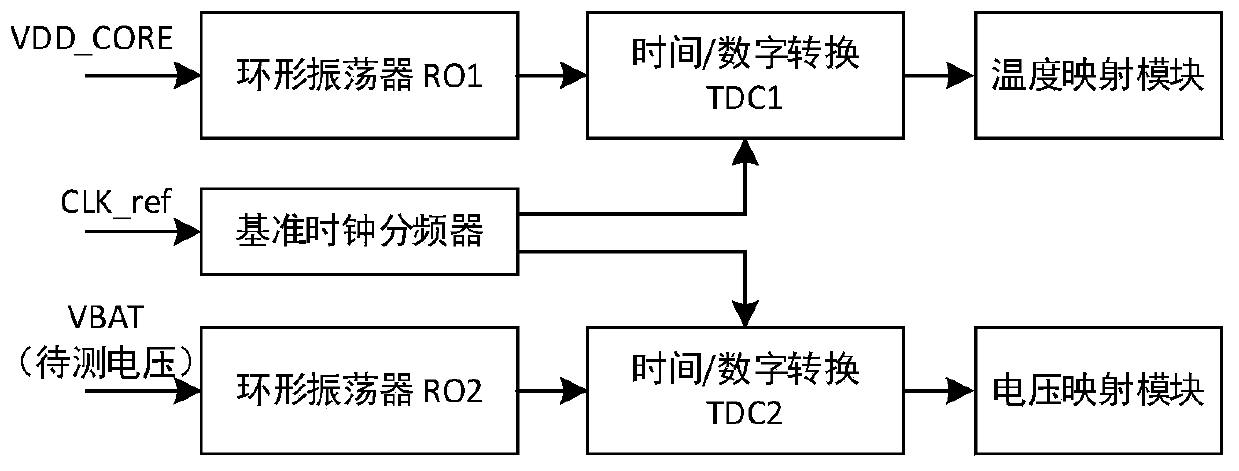

[0050] Based on the above-mentioned power supply system, the schematic diagram of the present invention is as follows figure 2 As shown, it includes two ring oscillators RO1 and RO2, two time / digital converters TDC1 and TDC2, a temperature mapping module, a voltage mapping module and a reference clock divider module. Wherein, the reference clock may be a system reference clock provided by a crystal oscillator, the ring oscillator RO1 is powered by the core domain power supply voltage VDD_CORE, and the ring oscillator RO2 is powered by the battery voltage VBAT. The reference clock is respectively connected to TDC1 and TDC2 after the reference clock frequency divider, and the output terminals of TDC1 and TDC2 are respectively connected to the temperature mapping module and the voltage mapping module.

[0051] Due to the carrier mobility μ of the MOS tube n , saturated drain-source voltage V dsat and threshold voltage V th Parameters such as process (Process), voltage (Voltag...

no. 2 example

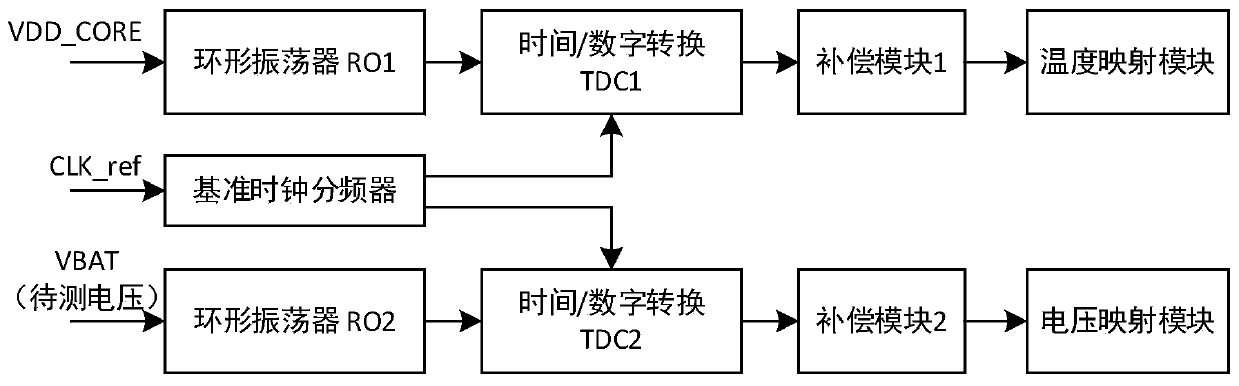

[0086] The description of the first embodiment is based on the condition that the chip production process parameters do not deviate. If there is a deviation in the process parameters, a compensation module needs to be used to compensate the temperature and voltage. Therefore, the second embodiment of the present invention adds a temperature compensation module 1 and a voltage compensation module 2, and uses the compensation module 1 and the compensation module 2 to respectively compensate the digital values X1 and X2 corresponding to the temperature and voltage to obtain accurate temperature and voltage value. It is another embodiment of the present invention, such as image 3 shown. In addition, the compensation module also has a compensation function for temperature nonlinearity and voltage nonlinearity.

[0087] For the calibration of process deviation: Since the process deviation will cause changes in f0, Kvco and TC, the count value obtained by counting will change. ...

no. 3 example

[0091] In the second embodiment, in order to compensate the variation of the process deviation, we adopt the method of multiplying the difference of the count value by a compensation coefficient. It can be seen from the formula that another compensation method is to change the counting cycle K to get the same effect. By changing the frequency division ratio of the programmable frequency divider, the number of counting cycles K can be changed to compensate for changes in process deviations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com