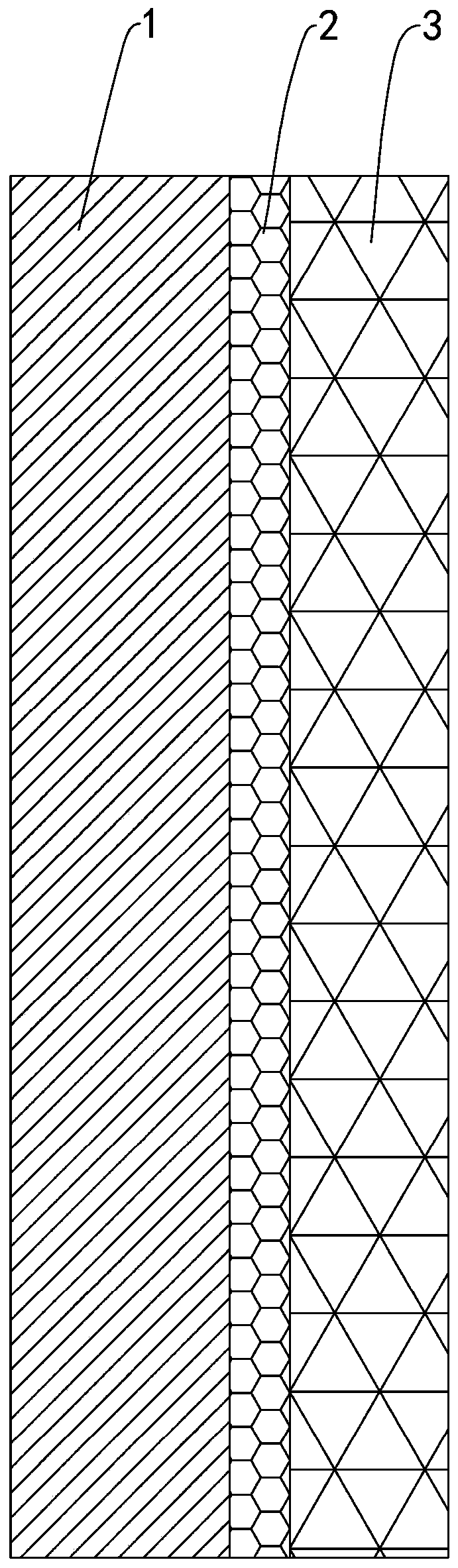

Bacteriostatic ultrafiltration membrane assembly

A technology of ultrafiltration membranes and components, applied in ultrafiltration, membrane, membrane technology and other directions, can solve the problems of increasing time and labor costs, affecting the performance of ultrafiltration membranes, and cumbersome regular cleaning, and achieving good biocompatibility and maintenance. Simple and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] In a specific embodiment, the preparation method of the antibacterial layer 3 comprises the following steps:

[0042] Step 1, mixing recycled pulp, cellulose acetate and starch under dry conditions, putting them into a homogenizer and mixing evenly to obtain the first mixture;

[0043] Step 2, adding ethanol to the first mixture, stirring at room temperature for 10-30min, to obtain pulp;

[0044] Step 3, the paper pulp is fished, dried and cut to form raw paper;

[0045] Step 4: Mix octacosanol, juglone and ethanol, stir and dissolve to obtain a spray solution, spray the spray solution on the surface of the raw paper, after spraying, dry at 50-70°C for 1-2 hours to obtain an antibacterial layer .

[0046] In a specific embodiment, the amount of ethanol used in step two and step four is the same.

Embodiment 1

[0048] Preparation of ultrafiltration membrane layer: Weigh 100g polysulfone, 30g polyethylene glycol and 700g N-methylpyrrolidone, mix and stir for 20min at room temperature to obtain a casting solution, place the casting solution in a vacuum defoamer for 1 hour, degassing After soaking, the film is scraped and formed by a flat film scraping machine and then dried to obtain an ultrafiltration membrane with a thickness of 200 μm.

[0049] Preparation of antibacterial layer: take 100g recycled paper pulp, 20g cellulose acetate and 80g starch, mix and stir in a homogenizer for 20min to obtain the first mixture, add 250g ethanol to the first mixture, and stir at room temperature for 10min to obtain paper pulp, After the paper pulp is scooped, air-dried and sheared to form raw paper, 10g of octacosanol, 10g of juglone and 250g of ethanol are weighed, stirred and dissolved to obtain a spraying liquid, which is sprayed on the surface of the raw paper, and after the spraying is comple...

Embodiment 2

[0052] Preparation of ultrafiltration membrane layer: Weigh 250g of polyethersulfone, 80g of polyvinylpyrrolidone and 850N,N-dimethylformamide, mix and stir for 30min at room temperature to obtain a casting solution, and place the casting solution in a vacuum defoamer After degassing for 2 hours, after the degassing is completed, the membrane is scraped and formed by a flat-plate scraping machine and then dried to obtain an ultrafiltration membrane. The thickness of the ultrafiltration membrane is 200 μm.

[0053] Prepare antibacterial layer: take 200g regenerated pulp, 50g cellulose acetate and 200g starch, mix and stir in a homogenizer for 30min to obtain the first mixture, add 350g ethanol to the first mixture, stir at room temperature for 30min to obtain paper pulp, After the paper pulp is scooped, air-dried and cut to form raw paper, weigh 50g of octacosanol, 30g of juglone and 350g of ethanol, stir and dissolve to obtain a spraying liquid, and spray the spraying liquid on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com