Processing technique of vacuum high-temperature sterilization soft-packaged duck seasoned with soy sauce using tender duck meat as raw material

A high-temperature sterilization and processing technology, applied in the field of food processing, can solve problems such as poor taste, and achieve the effects of shortening preparation time, improving taste and shortening preparation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

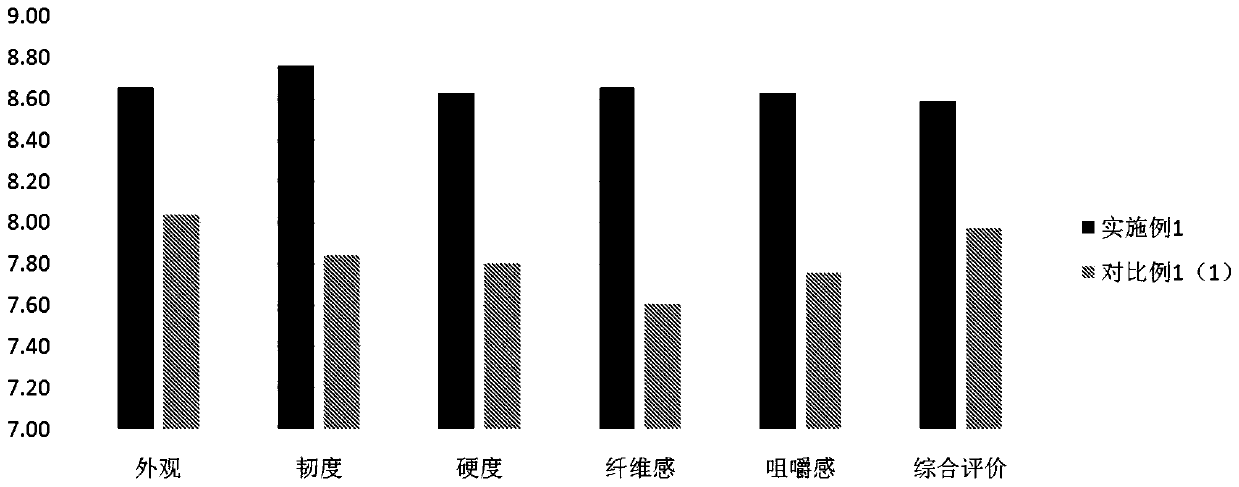

Embodiment 1

[0055] The invention discloses a processing technology for vacuum high-temperature sterilization soft-packed sauced duck products using tender duck meat as raw material, which is obtained by the processing technology comprising the following steps:

[0056] (1) Spice water boiling: the special spice bag (star anise 1-2%, Chinese prickly ash 1.5-2%, bay leaf 3-5%, capsicum 3-5%, white coriander 1-2%, Angelica dahurica 0.5-1%, dried ginger 2-4%, tangerine peel 1-3%, grass fruit 0.8-1%, the percentages are mass percentages relative to the water quality) put into 1000g of water and boil for 120min, then take out, Cool and refrigerate the boiled spices in buckets for later use.

[0057] (2) Thawing selection: Thaw tender duck wings in water until there are no ice cubes. The water temperature is controlled below 16°C to ensure the food safety of tender duck wings. At the same time, it can also prevent the meat from being easily acidified due to the temperature rise during the rollin...

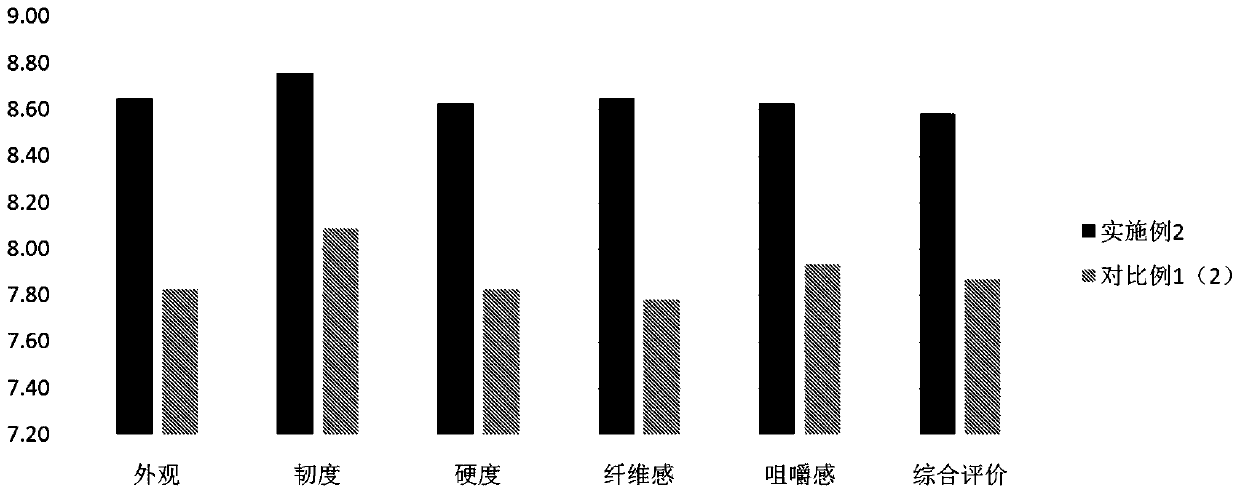

Embodiment 2

[0067] The invention discloses a processing technology for vacuum high-temperature sterilization soft-packed sauced duck products using tender duck meat as raw material, which is obtained by the processing technology comprising the following steps:

[0068] (1) Spice water boiling: Put the spice packet made of spice water into 1000g of water and boil for 120 minutes, then take it out, put the boiled spice water in barrels, cool and refrigerate for later use.

[0069] (2) Thawing selection: thaw tender duck wings in water until there are no ice cubes, and the water temperature should be controlled below 16°C;

[0070] (3) Low-temperature vacuum tumbling seasoning: Clean the thawed tender duck wings with clean water, drain and send to the tumbling machine, then add spices and water to mix, and vacuum tumbling for 4 hours. The specific process: -0.06Mpa vacuum degree , the rotation speed is 7r / min, the temperature is 2°C, and there are 6 stages of rolling and kneading, ① tumble a...

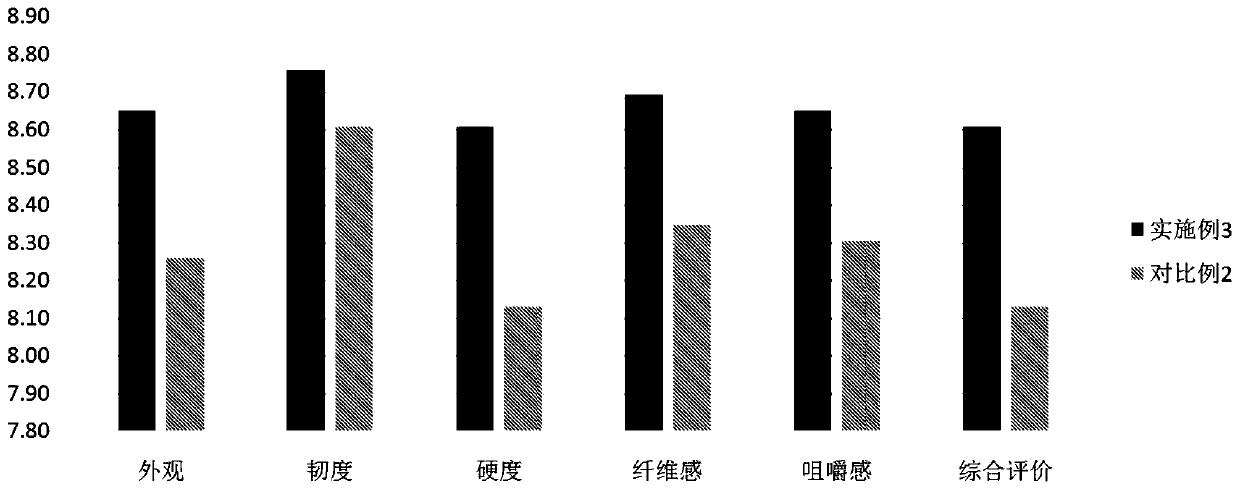

Embodiment 3

[0079] The invention discloses a processing technology for vacuum high-temperature sterilization soft-packed sauced duck products using tender duck meat as raw material, which is obtained by the processing technology comprising the following steps:

[0080] (1) Spice water boiling: Put the special spice bag for boiling spice water into 1000g of water and boil for 120 minutes, then take it out, put the boiled spice water in buckets, cool and refrigerate for later use.

[0081] (2) Thawing selection: thaw tender duck wings in water until there are no ice cubes, and the water temperature should be controlled below 16°C;

[0082](3) Low-temperature vacuum tumbling seasoning: Clean the thawed tender duck wings with clean water, drain and send to the tumbling machine, then add spices and water to mix, and vacuum tumbling for 5 hours. The specific process: -0.04Mpa vacuum degree , the rotation speed is 10r / min, the temperature is 0°C, and there are 6 stages of tumbling and kneading, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com