Gypsum slurry foam powdering system and construction method thereof

A technology for gypsum slurry and pulverizing system, which is applied in separation methods, chemical instruments and methods, evaporator regulation/control, etc., can solve the problems of gypsum slurry foam overflow and low cost, and achieve the effect of preventing outflow and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Take the gypsum slurry foam produced during the flue gas desulfurization process of a certain power plant as an example. The main component of desulfurization gypsum is calcium sulfate dihydrate, and the moisture content of the gypsum foam is about 5%, which has certain adsorption and corrosion properties. After the gypsum slurry foam is collected, it is treated with the pulverizing system of the present invention.

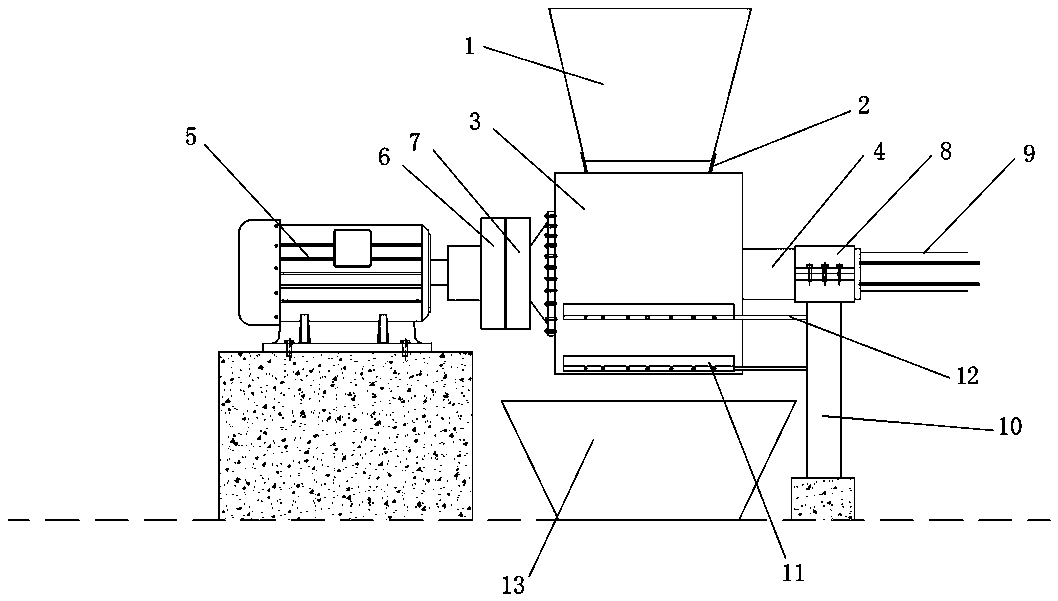

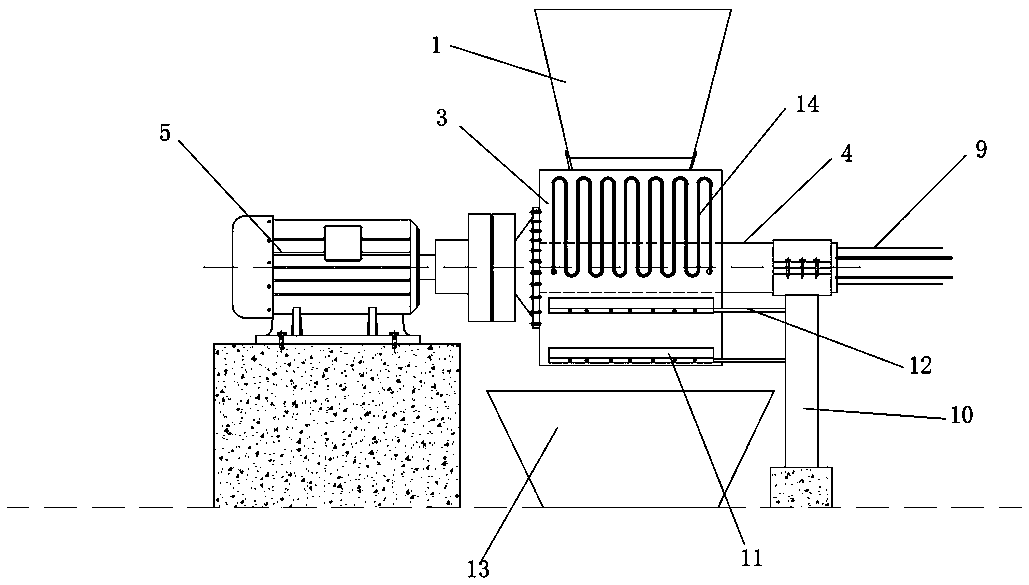

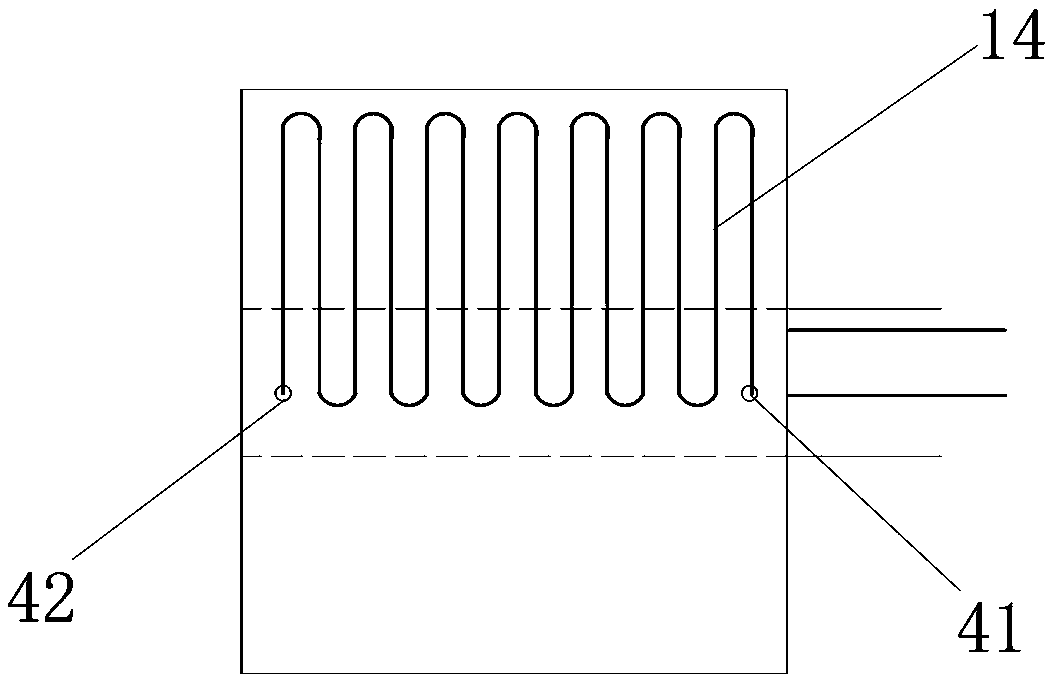

[0036] Such as figure 1 and figure 2 As shown, the gypsum slurry foam pulverizing system includes a feeding unit, a pulverizing unit and a collecting unit; the feeding unit includes a foam collecting tank 1 and a feed tank 2 connected to the bottom side of the collecting tank; the pulverizing unit It includes a dehumidification drum 3 , a central cylinder 4 connected inside the dehumidification drum 3 , a transmission motor 5 connected to one end of the dehumidification drum 3 , a heating main pipe 9 connected to the end of the central cylinder 4 away fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com