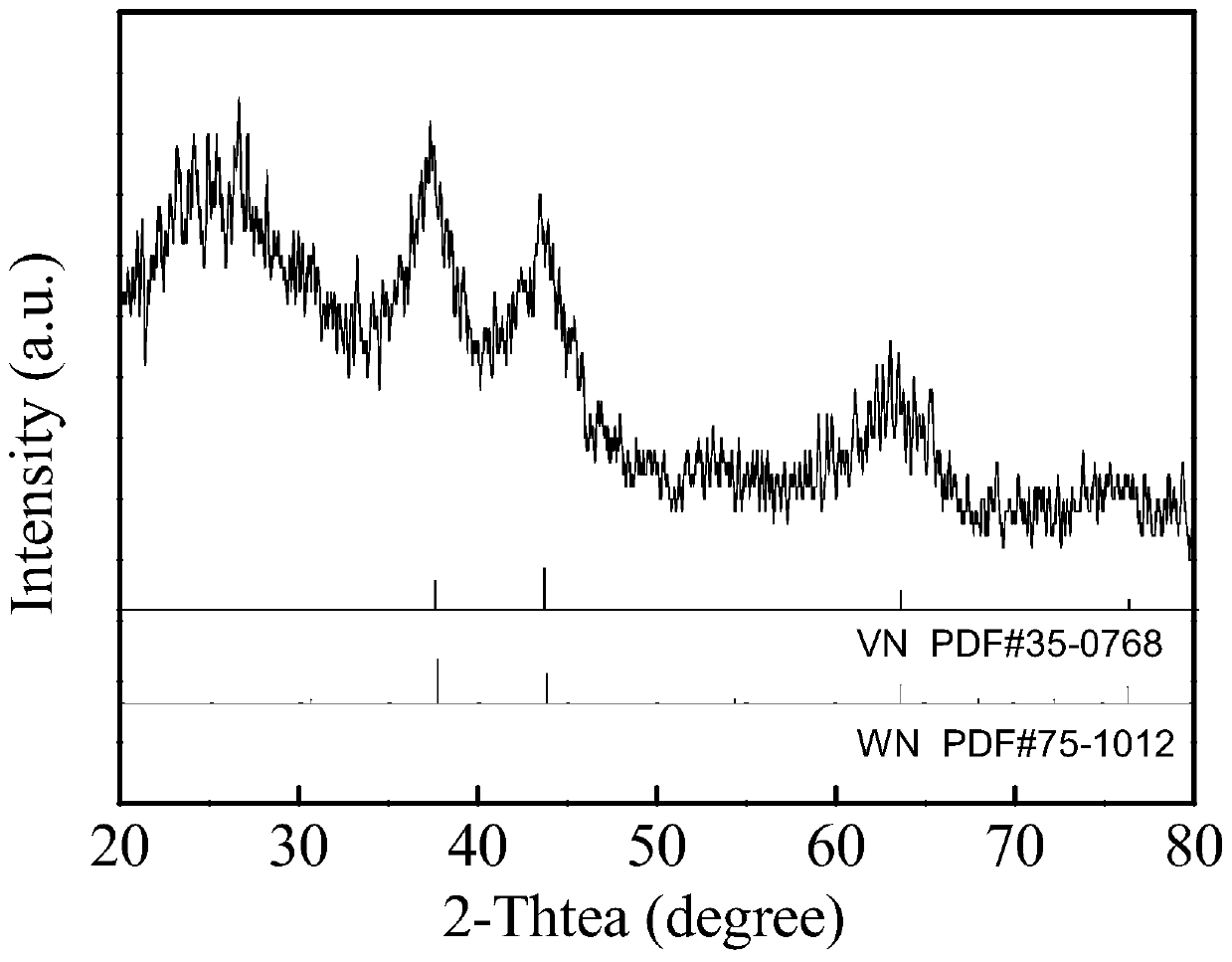

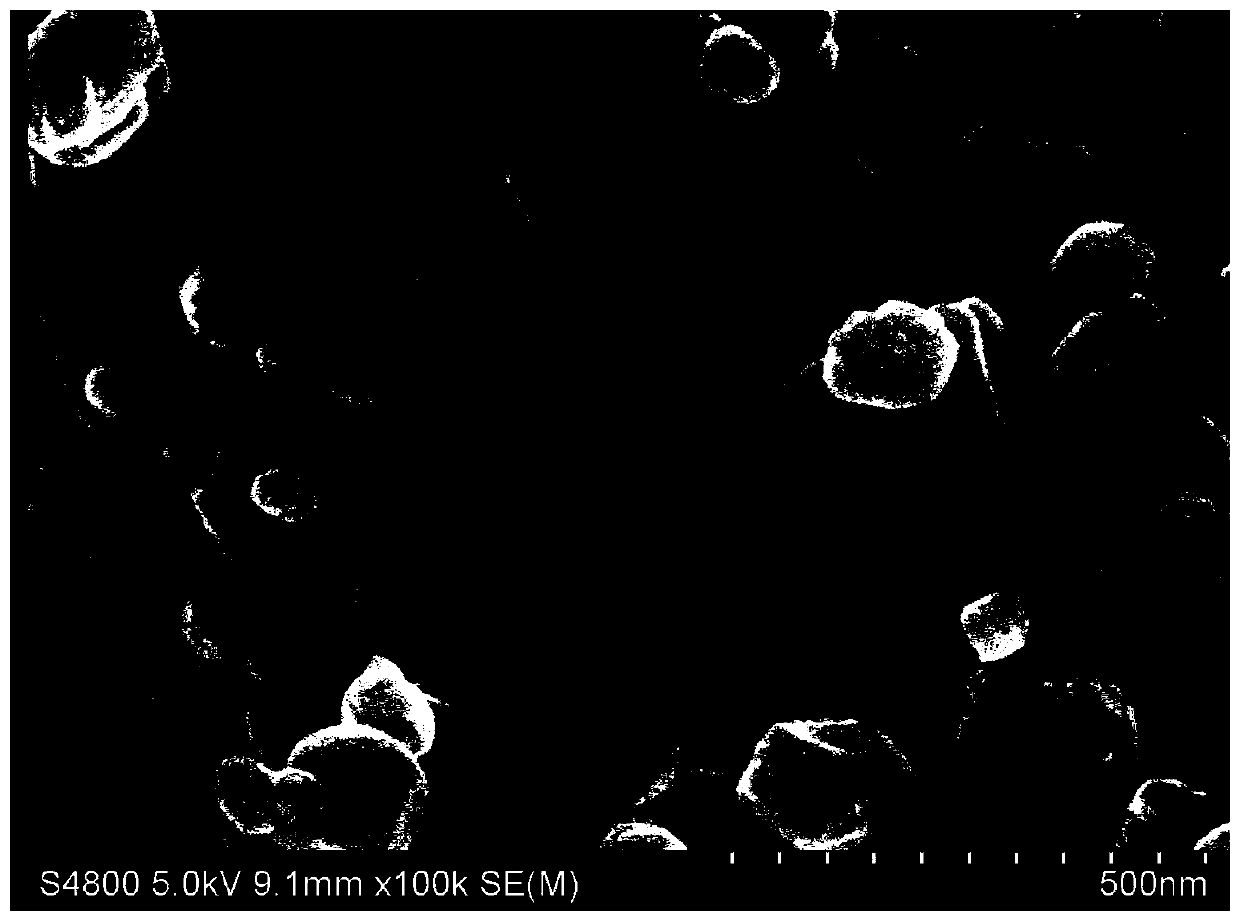

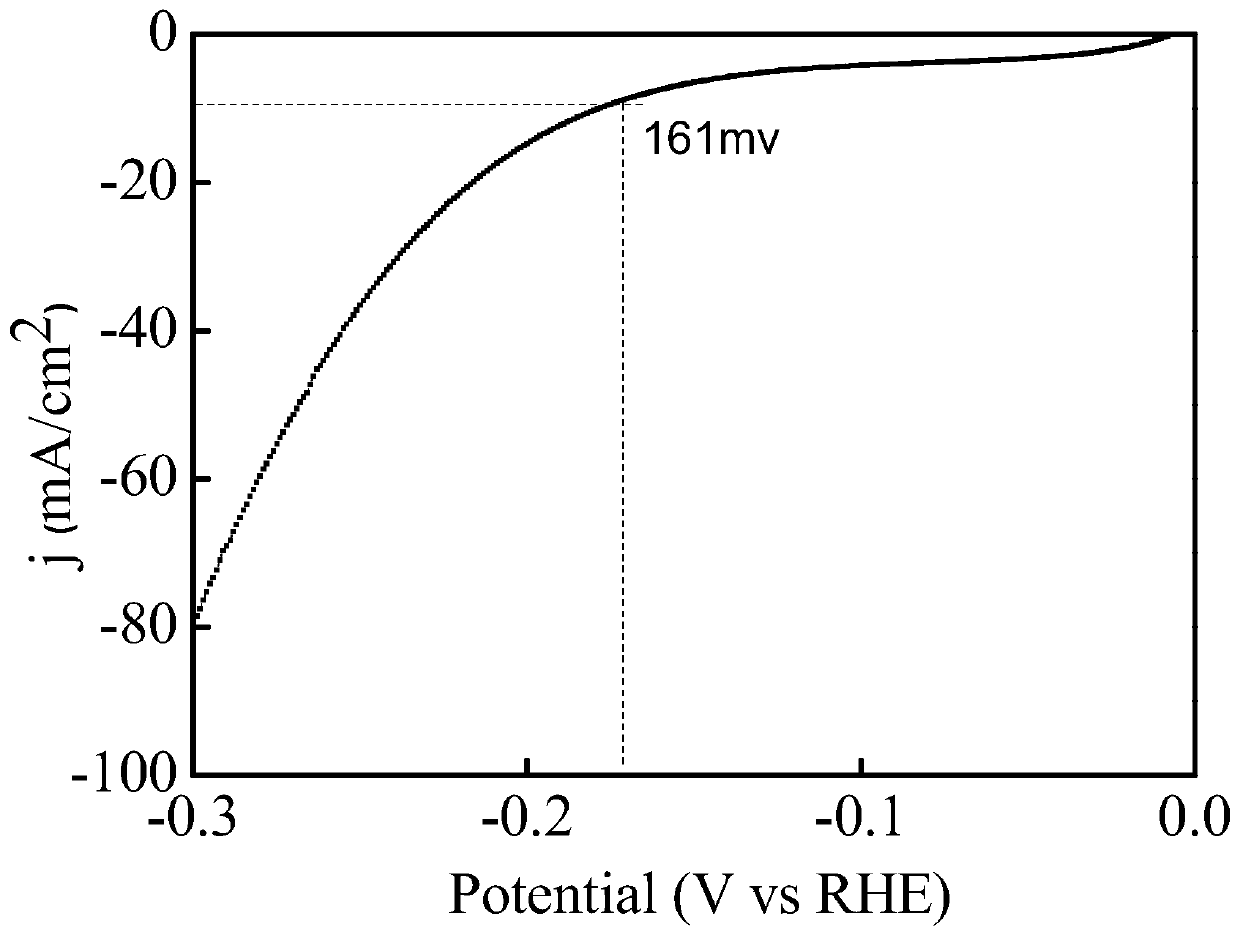

Preparation method and application of VN@WN nanoparticle with electrocatalysis function

A nanoparticle and electrocatalytic technology, applied in chemical instruments and methods, physical/chemical process catalysts, electrodes, etc., can solve the problems of incapable of large-scale industrial production, hindrance to practical application, high price of platinum, etc., and achieve good hydrogen production performance , easy industrial production, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) First, press dicyandiammonium, ammonium metavanadate, and phosphotungstic acid. C 2 h 4 N 4 :NH 4 VO 3 :H 3 o 40 PW 12 .xH 2 The mass ratio of O=50:5:2 mixes;

[0023] 2) Grind the above mixture for 20 minutes and pass through 60 sieves to obtain the mixture, put the mixture into a porcelain boat, place the porcelain boat in a tube-type atmosphere furnace, and put two furnace plugs at both ends of the tube with an interval of 5cm;

[0024] 3) Introduce the inert gas argon into the tubular atmosphere furnace, perform 3 times of pumping and replenishing air, exhaust the air inside, control the air pressure in the tube to -1~0MPa, heat to 700°C at a heating rate of 10°C / min and keep it warm 180min;

[0025] 4) The sample obtained after cooling was ground in a mortar for 20 min to obtain VN@WN nanoparticles.

Embodiment 2

[0027] 1) First, press dicyandiammonium, ammonium metavanadate, and phosphotungstic acid. C 2 h 4 N 4 :NH 4 VO 3 :H 3 o 40 PW 12 .xH 2 The mass ratio of O=50:5:3 is mixed;

[0028] 2) Grind the above mixture for 25 minutes and pass through 60 sieves to obtain the mixture, put the mixture into a porcelain boat, place the porcelain boat in a tube-type atmosphere furnace, and put two furnace plugs at both ends of the tube with an interval of 5cm;

[0029] 3) Introduce the inert gas argon into the tube atmosphere furnace, perform 3 times of pumping and replenishing, exhaust the air inside, control the pressure inside the tube to -1~0MPa, heat to 750°C at a heating rate of 10°C / min and keep it warm 160min;

[0030] 4) The sample obtained after cooling was ground in a mortar for 22 minutes to obtain VN@WN nanoparticles.

Embodiment 3

[0032] 1) First, press dicyandiammonium, ammonium metavanadate, and phosphotungstic acid. C 2 h 4 N 4 :NH 4 VO 3 :H 3 o 40 PW 12 .xH 2 The mass ratio of O=50:5:2.5 mixes;

[0033] 2) Grind the above mixture for 30 minutes and pass through 60 sieves to obtain the mixture, put the mixture into a porcelain boat, place the porcelain boat in a tube-type atmosphere furnace, and place two furnace plugs at both ends of the tube with an interval of 5 cm;

[0034] 3) Introduce the inert gas argon into the tube-type atmosphere furnace, perform 3 times of pumping and replenishing air, exhaust the air inside, control the pressure in the tube to -1~0MPa, heat to 800°C at a heating rate of 10°C / min and keep it warm 150min;

[0035] 4) The sample obtained after cooling was ground in a mortar for 28 min to obtain VN@WN nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com