Electrochemical device for preparing hydrogen peroxide and application thereof

A hydrogen peroxide and electrochemical technology, applied in chemical instruments and methods, oxidized water/sewage treatment, electrodes, etc., can solve the problems of unsustainable supply of hydrogen peroxide and difficult engineering applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

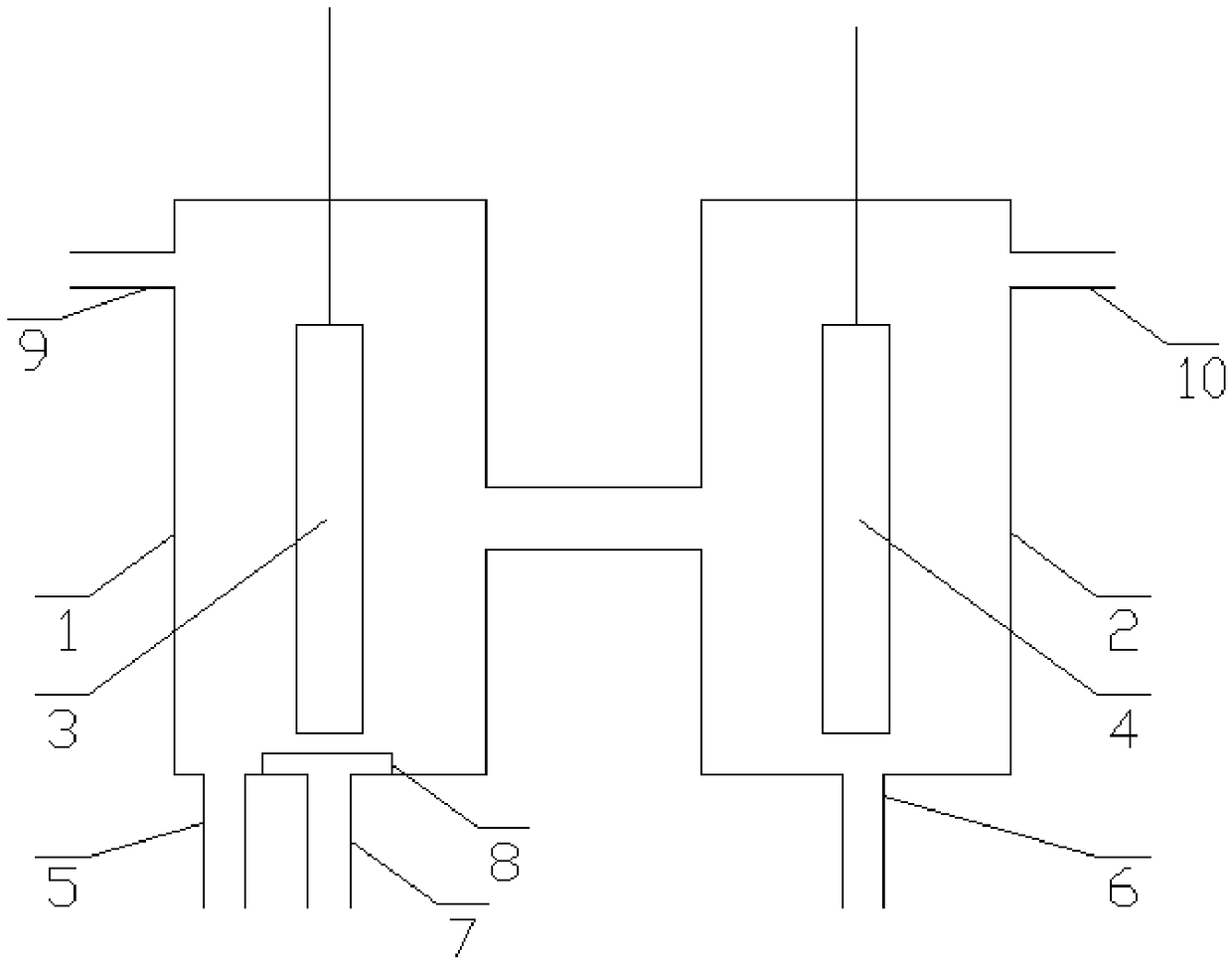

[0018] Specific implementation mode one: combine figure 1 Describe this embodiment, the electrochemical device for preparing hydrogen peroxide in this embodiment is composed of cathode chamber 1, anode chamber 2, cathode 3 and anode 4;

[0019] The cathode chamber 1 and the anode chamber 2 are arranged side by side, and the side of the cathode chamber 1 and the side of the anode chamber 2 are connected through pipelines; the cathode 3 and the anode 4 are flat plates, the cathode 3 is vertically arranged in the cathode chamber 1, and the anode 4 is vertically arranged It is arranged in the anode chamber 2; the bottom of the cathode chamber 1 is provided with a cathode chamber water inlet pipe 5 and an oxygen inlet pipe 7; the cathode chamber 1 is provided with a gas distribution chamber 8 below the cathode 3, and the top surface of the gas distribution chamber 8 is a porous plate; The bottom surface of 3 is arranged towards the midline of the top surface of gas distribution cha...

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment is different from Embodiment 1 in that: the inlet end of the oxygen inlet pipe 7 communicates with the gas outlet of the oxygen generator. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0027] Specific embodiment three: this embodiment is different from specific embodiment one or two in that: the cathode 3 is connected to the negative pole of the power supply through a wire; the anode 4 is connected to the positive pole of the power supply through a wire; 10mA / cm 2 ; The minimum current density applied to the anode 4 is 10mA / cm 2 . Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com