Process for preparing integrated renewable fuel double effect oxygen electrode diffusion layer

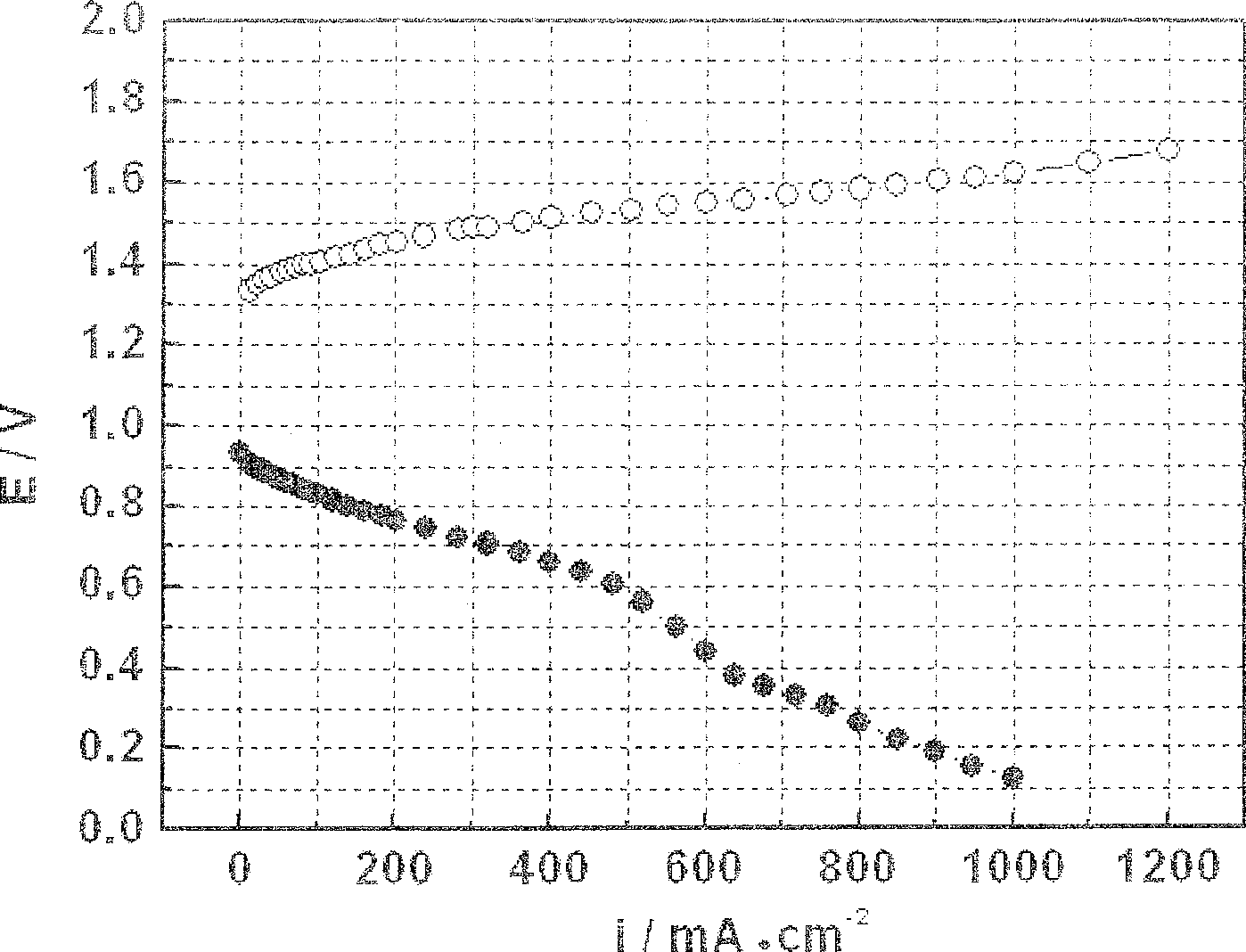

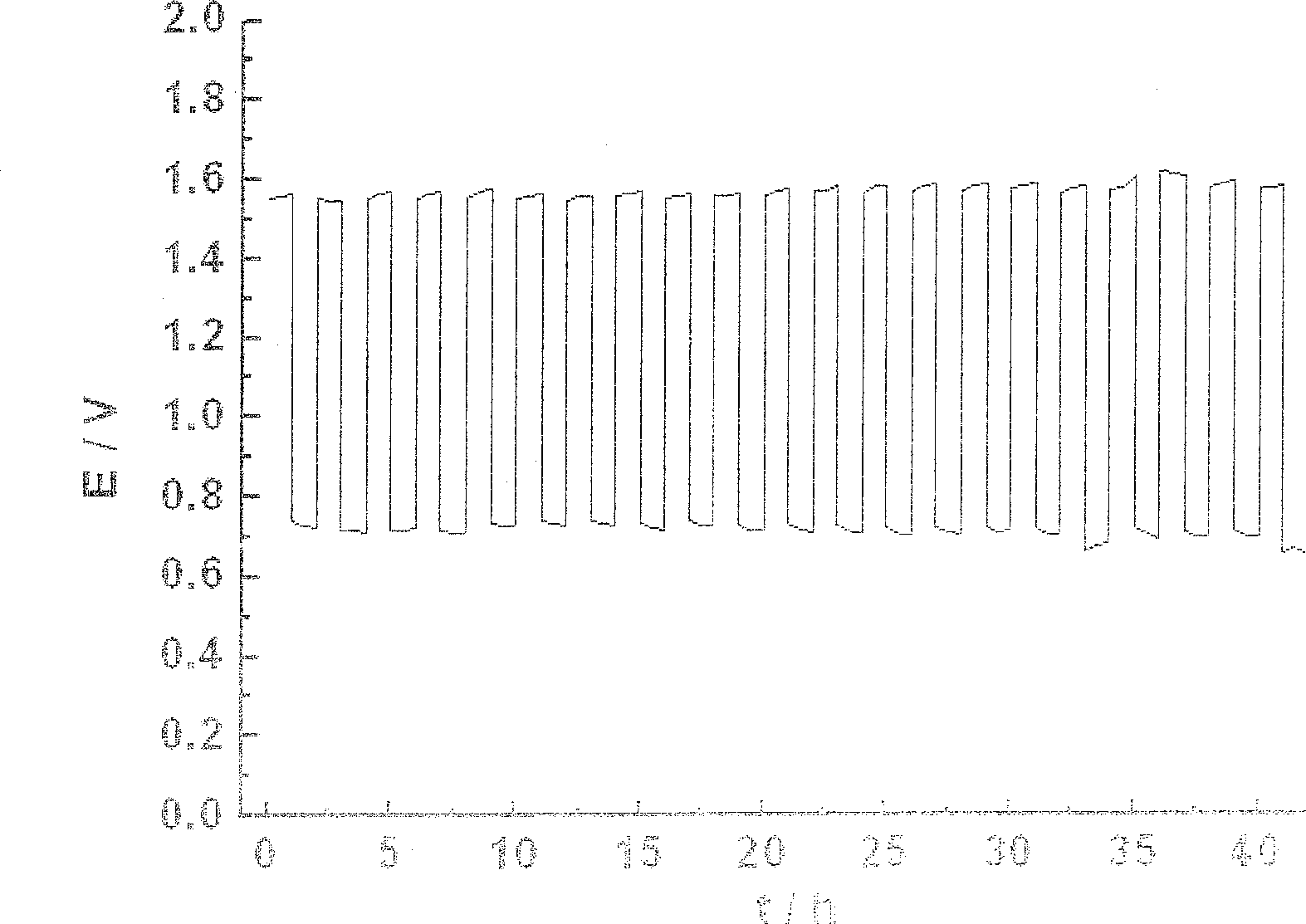

A double-effect oxygen electrode and fuel cell technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of high porosity and corrosion resistance, and achieve the goal of improving battery performance, high conductivity, and expanding the three-phase reaction area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add 0.9 g of Ir powder into 10% hydrochloric acid solution, heat treatment for 10 min, and suction filter or centrifuge to obtain the treated Ir powder. Add Ir powder to 30ml of H 2 PtCl 6 .xH 2 O solution (weight concentration 1.5%), adjust the pH value to 2 with 5% NaOH solution. Add 50 ml of hydrazine hydrochloride solution (weight concentration 15%), reflux for 10 h, filter, and dry to obtain 1 g of Ir powder for electroless Pt plating.

[0039] Weigh 1g of Pt-plated Ir powder, add ethanol, add 5g of PTFE emulsion (weight concentration 10%), and 0.5g of ammonium carbonate, after ultrasonic mixing, the self-supporting diffusion layer precursor is obtained by plasticizing and rolling.

[0040] Add high-porosity titanium mesh (80% porosity) into 10% hydrochloric acid solution, heat it for 10 minutes, take it out, and dry it for later use. Add the titanium mesh to 30ml of H 2 PtCl 6 .xH 2 O solution (weight concentration 1.5%), adjust the pH value to 2 with 5% Na...

Embodiment 2

[0043] Add 0.9g of Ti powder into 10% hydrochloric acid solution, heat for 10 minutes, and filter or centrifuge to obtain the treated Ti powder. Add Ti powder to 30ml of H 2 PtCl 6 .xH 2 O solution (weight concentration 1.5%), adjust the pH value to 2 with 5% NaOH solution. Add 50 ml of hydrazine hydrochloride solution (weight concentration 15%), reflux for 10 h, filter, and dry to obtain 1 g of Ti powder for electroless Pt plating.

[0044] Weigh 1g of Pt-plated Ti powder and add ethanol, add 5g PTFE emulsion (weight concentration 10%), and 0.5g ammonium carbonate, after ultrasonic mixing, adopt drawing process to prepare on the PTFE film, remove the PTFE film after hot pressing, A self-supporting diffusion layer precursor is prepared.

[0045] Add high-porosity titanium mesh (80% porosity) into 10% hydrochloric acid solution, heat it for 10 minutes, take it out, and dry it for later use. Add the titanium mesh into the electroless nickel plating solution. The electroles...

Embodiment 3

[0048] Add 0.9g of Ti powder into 10% hydrochloric acid solution, heat for 10 minutes, and filter or centrifuge to obtain the treated Ti powder. 1g RuCl 3 and 1.4g SnCl 4 Dissolve in 50ml of isopropanol, add the treated Ti powder, heat and stir, evaporate the solvent, vacuum dry, and sinter at 500°C for 1h to obtain 1.8g loaded RuO 2 and SnO 2 Ti powder of oxygen evolution catalyst (mass ratio Ti powder: RuO 2 : SnO 2 is 5:2:3).

[0049] Weigh 1g loaded with RuO 2 and SnO 2 Add ethanol to the Ti powder of the oxygen evolution catalyst, add 5g PTFE emulsion (weight concentration 10%), and 0.5g ammonium carbonate, after ultrasonic mixing, scrape coating on the PTFE membrane, remove the PTFE membrane after hot pressing, and obtain an oxygen evolution electrocatalytic Active self-supporting diffusion layer precursor.

[0050] Add high-porosity titanium mesh (80% porosity) into 10% hydrochloric acid solution, heat it for 10 minutes, take it out, and dry it for later use. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com