Welding wheel assembly device for strip steel on-line narrow lap joint seam welding machine

A seam welding machine and strip steel technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve problems such as difficulty in observing the use of conductive parts, difficulty in processing and assembling parts, and burnout of taper bushings, etc. , to achieve the effect of easy observation and maintenance, stable and reliable electrical conductivity, and reduced equipment failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

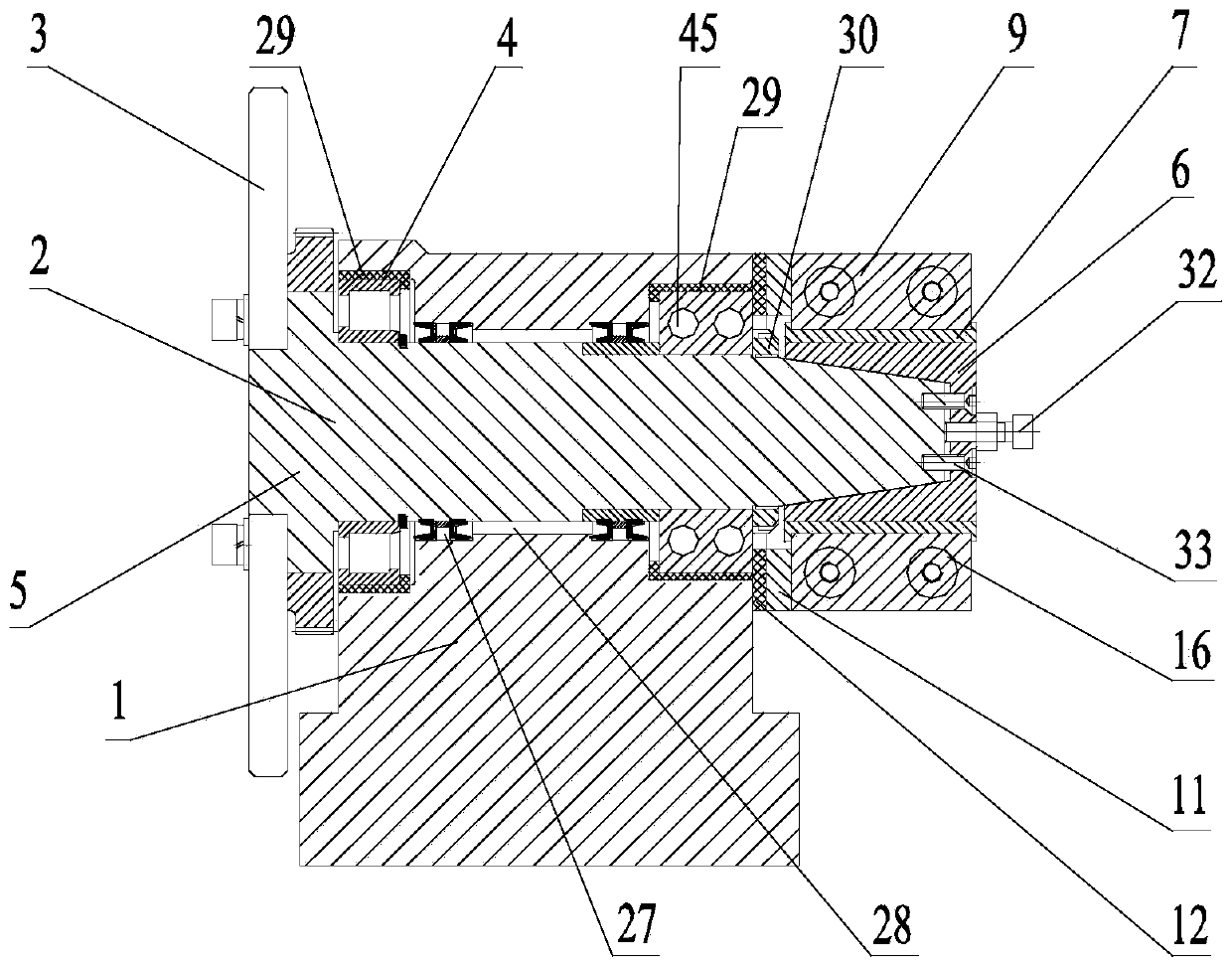

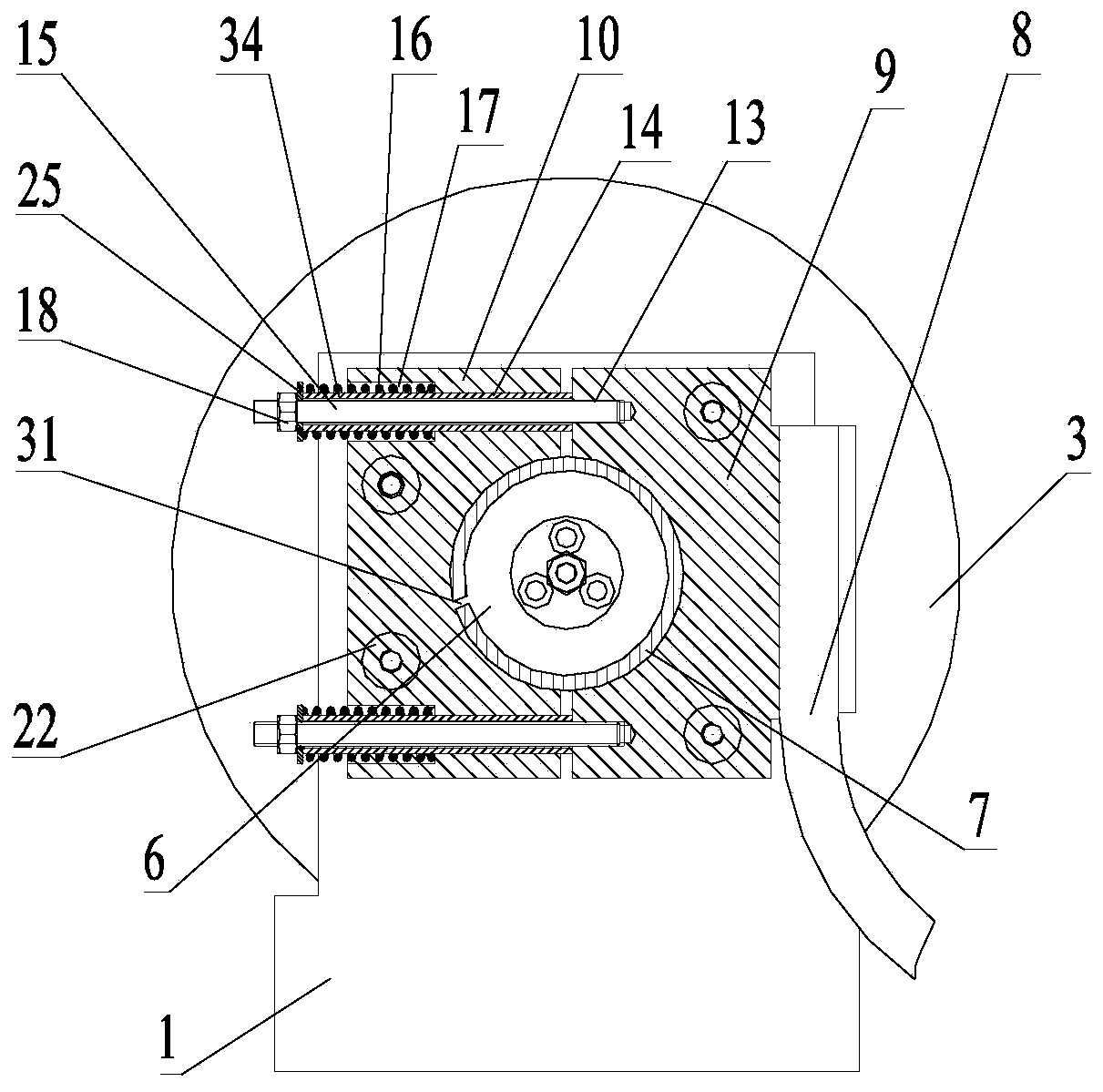

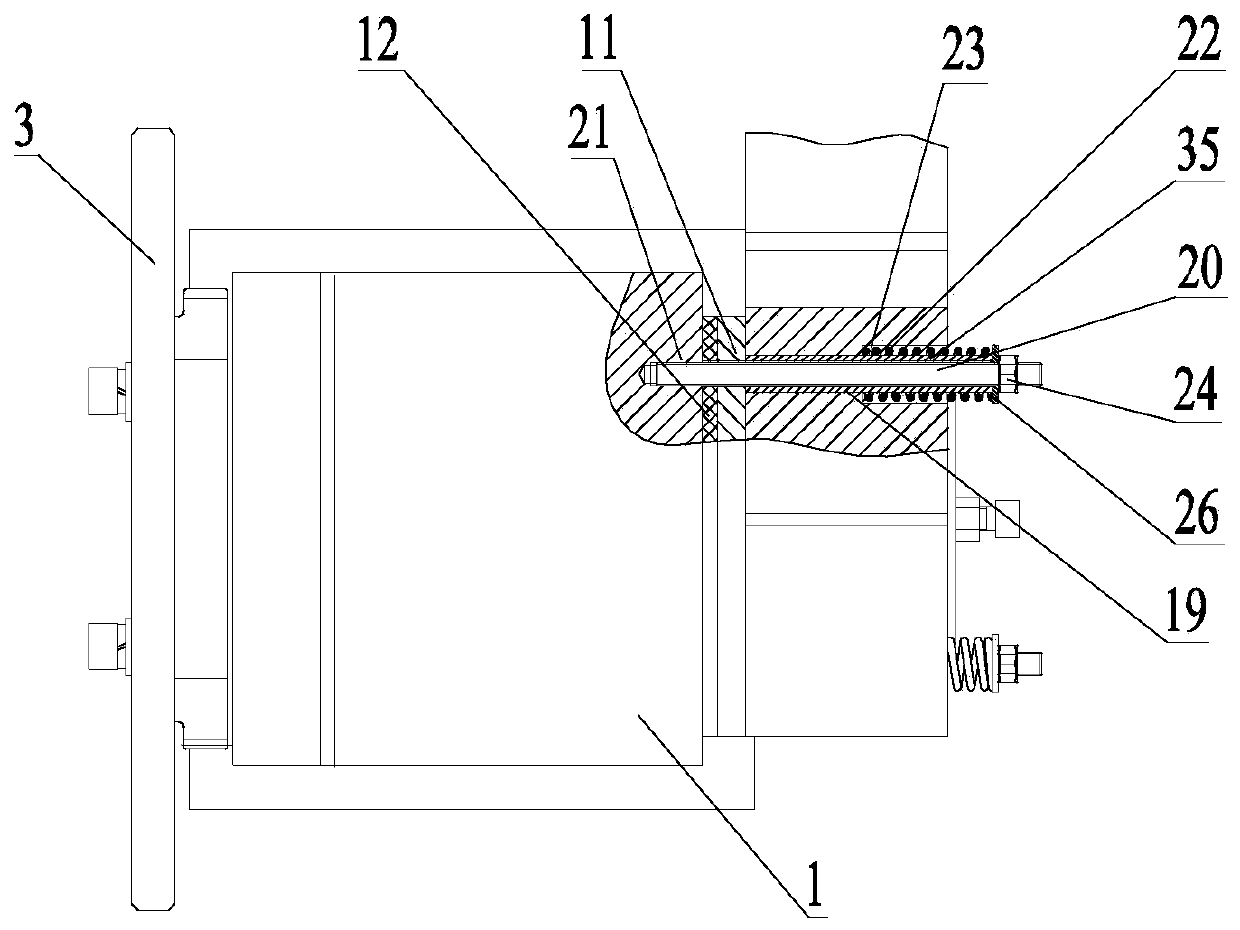

[0039] Such as figure 1 and figure 2 As shown, the welding wheel assembly device of the present invention used for strip steel on-line narrow lap seam welding machine includes an electrode wheel support 1 and an electrode wheel 3 installed on the wheel shaft 2, and the wheel shaft 2 passes through the front bearing arranged at the front end 4 and the rear bearing 45 located at the rear end are installed in the step hole 5 in the horizontal direction of the electrode wheel support 1, the front bearing 4, the rear bearing 45 and the electrode wheel support 1 are all padded with a protective sleeve 29, and the wheel shaft 2 The tail hangs on the outside of the electrode wheel support 1, and the tail of the wheel shaft 2 is fixedly covered with a tapered shaft sleeve 6 through three screws 33. The tail of the wheel shaft 2 is an outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com