Novel heat pipe ball screw

A ball screw and heat pipe technology, used in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc. Application and other problems, to achieve the effect of optimizing the structure form and layout, simple structure and reducing temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

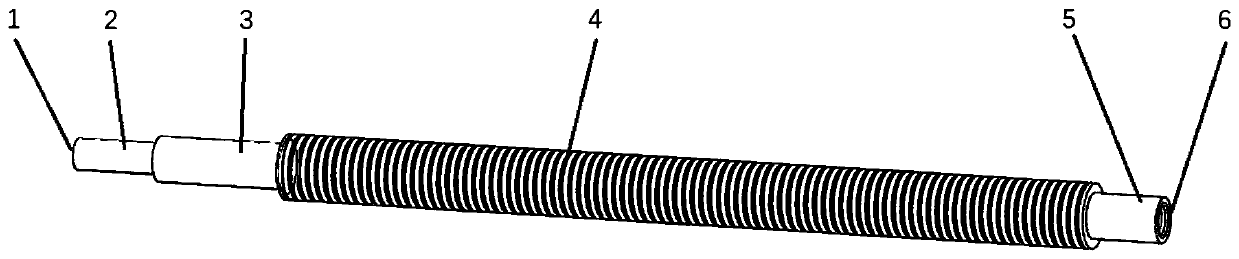

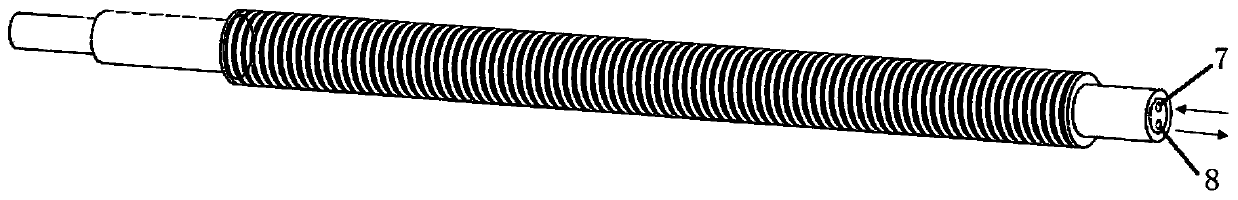

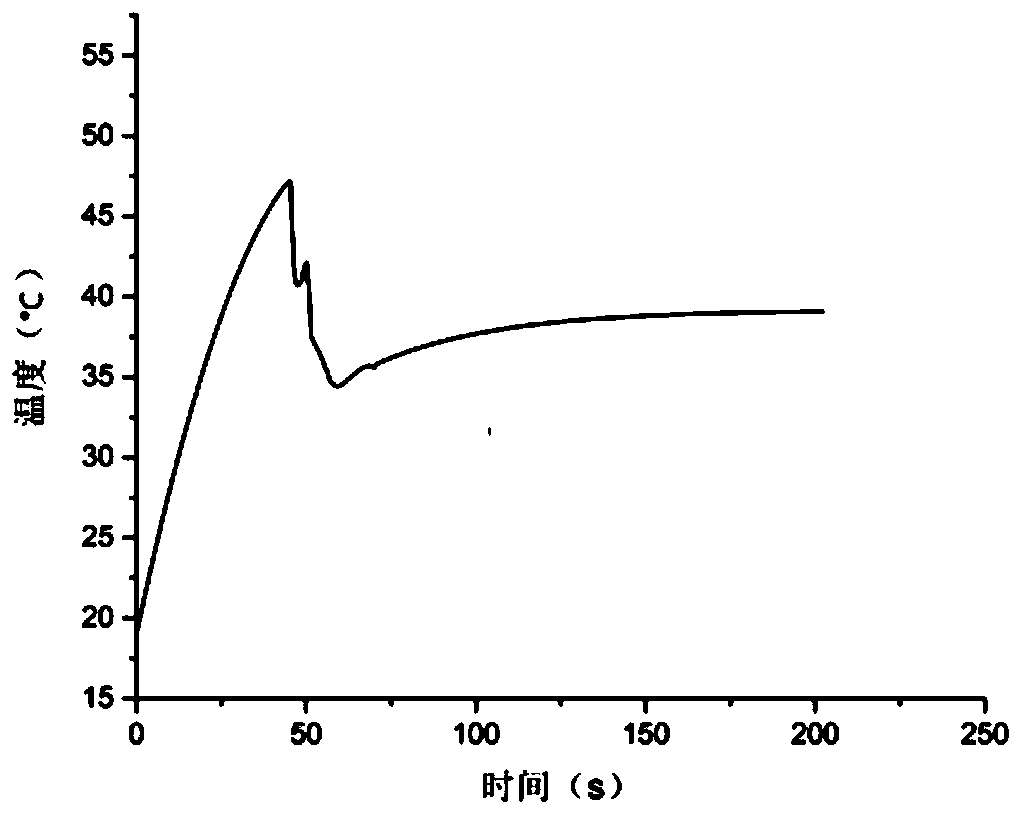

[0027] Such as figure 1 As shown, this embodiment provides a new type of heat pipe ball screw, including a screw body, a heat pipe flow channel, a working fluid, and a flow channel plug. The screw body is a stepped shaft member, and the screw body includes a connecting section 2, The first support section 3, the external thread section 4, the second support section 5, the first support section 3 is arranged on the left side of the external thread section 4, the second support section 5 is arranged on the right side of the external thread section 4, and the connecting section 2 is arranged on the first On the left side of the support section 3, the connection section 2 is configured to be fixedly connected to the output end of the motor through a coupling, and the first support section 3 is configured to install a fixed end bearing to limit the axial and radial degrees of freedom of the screw body , the second support section 5 is configured to install a floating end bearing fo...

Embodiment 2

[0046] On the basis of Example 1, the number of heat pipe runners is 3, and each heat pipe runner is symmetrically and uniformly distributed in the radial section of the lead screw body, and the first ends of the three heat pipe runners communicate with each other. A liquid-absorbing core is fixedly arranged on the inner cavity wall of the flow channel, and the liquid-absorbing core is a multi-layer net tube core.

[0047] A liquid cooling area is provided on the right side of the second support section 5, so that the second end of the heat pipe flow path is always kept at a lower temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com