Preparation method of electronic grade hydrogen bromide

A hydrogen bromide, electronic-grade technology, applied in the field of preparation of electronic-grade hydrogen bromide, can solve problems such as strong corrosion, and achieve the effect of saving liquid nitrogen, reducing energy consumption and cooling consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

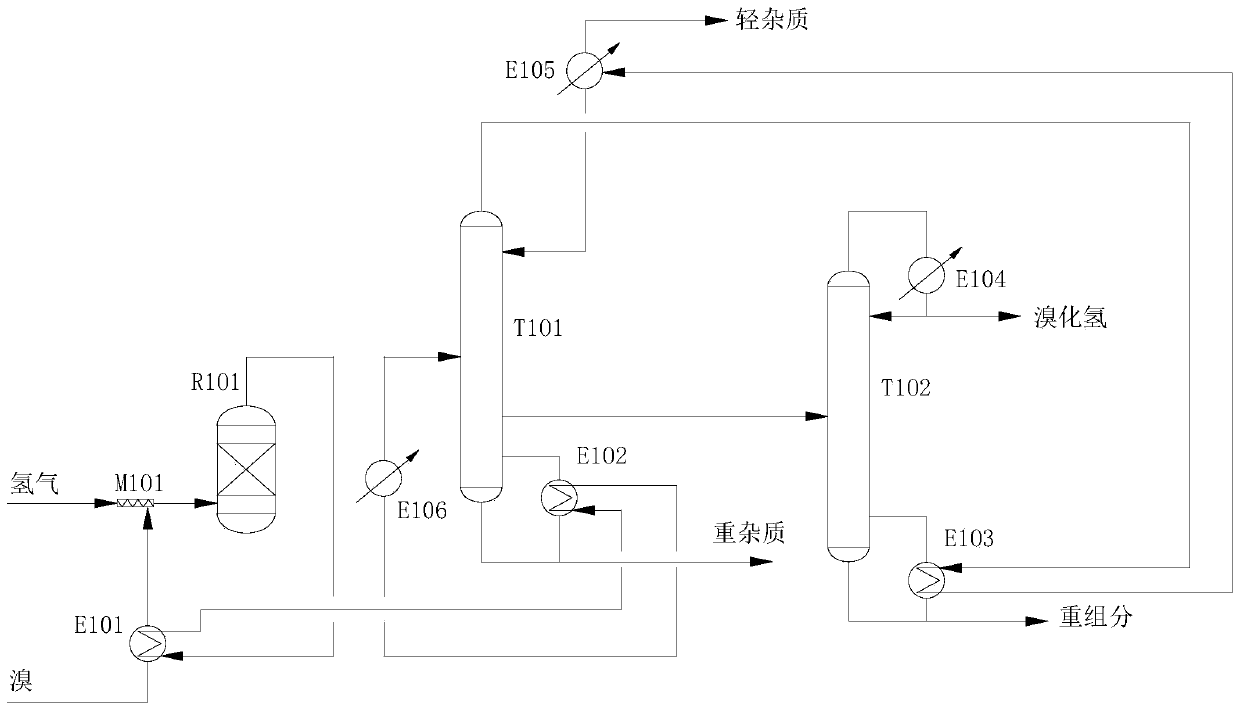

Embodiment 1

[0032] Bromine with a purity of 99.9% is fully vaporized by the preheater E101, and then enters the reactor R101 after being fully mixed with hydrogen with a purity of 99.999% in the mixer M101, wherein the molar ratio of bromine and hydrogen is 1:1, and the reactor R101 is filled with The supported Pt-Mo-W catalyst, bromine gas and hydrogen gas are catalytically combusted in the reactor to generate hydrogen bromide, the reaction temperature is 320°C, and the reaction pressure is 0.5MPa. The reaction product is extracted from the top of the reactor R101 and enters the preheater E101 and After heat exchange, the bromine raw material enters the reboiler E102 and exchanges heat with the material in the tower tank of the light removal tower T101. After the heat exchange, the reaction product is cooled to normal temperature by the cooler E106 and then enters the light removal tower T101. The operating pressure of the light removal tower T101 is 0.5MPa , the top gas phase is taken ou...

Embodiment 2

[0035] Bromine with a purity of 99.9% is fully vaporized by the preheater E101, and then enters the reactor R101 after being fully mixed with hydrogen with a purity of 99.999% in the mixer M101, wherein the molar ratio of bromine and hydrogen is 1:2, and the reactor R101 is filled with Supported Pt-Co-W catalyst, bromine and hydrogen react in the catalytic combustion reactor to generate hydrogen bromide, the reaction temperature is 400 ° C, the reaction pressure is 2 MPa, the reaction product is extracted from the top of the reactor R101 and enters the preheater E101 and bromine After heat exchange, the raw material enters T101 reboiler E102 to exchange heat with the material in the tower tank of light removal tower T101. The reaction product after heat exchange is cooled to normal temperature by cooler E106 and then enters light removal tower T101. The operating pressure of light removal tower T101 is 2MPa. The top gas phase is taken out and enters the reboiler E103 to exchang...

Embodiment 3

[0038]Bromine with a purity of 99.9% is fully vaporized by the preheater E101, and after being fully mixed with hydrogen with a purity of 99.999% in the mixer M101, it enters the reactor R101, wherein the molar ratio of bromine and hydrogen is 1:5, and the reactor R101 is filled with Supported Pt-Mo-Co catalyst, bromine gas and hydrogen gas are catalytically combusted in the reactor to generate hydrogen bromide, the reaction temperature is 360°C, and the reaction pressure is 5MPa. The reaction product is extracted from the top of the reactor R101 and enters the preheater E101 and bromine After heat exchange, the raw material enters the reboiler E102 to exchange heat with the material in the tower tank of the light removal tower T101. After the heat exchange, the reaction product is cooled to normal temperature by the cooler E106 and then enters the light removal tower T101. The operating pressure of the light removal tower T101 is 5MPa. The gaseous phase is recovered and enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com