Preparation method and application of ordered mesoporous carbon nanofiber array material

A nanofiber array, mesoporous carbon technology, applied in nanocarbon, material electrochemical variables, etc., can solve problems such as lack of preparation methods, and achieve the effect of simple method, cheap cost, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

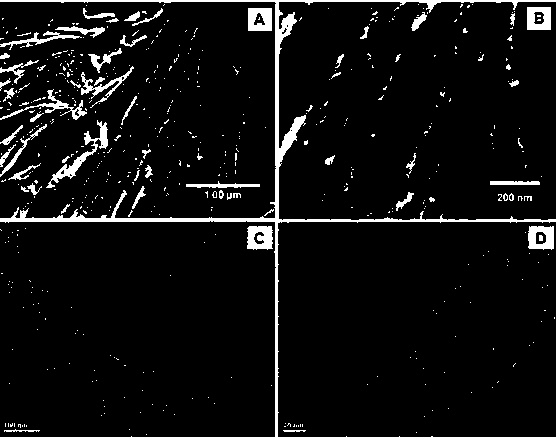

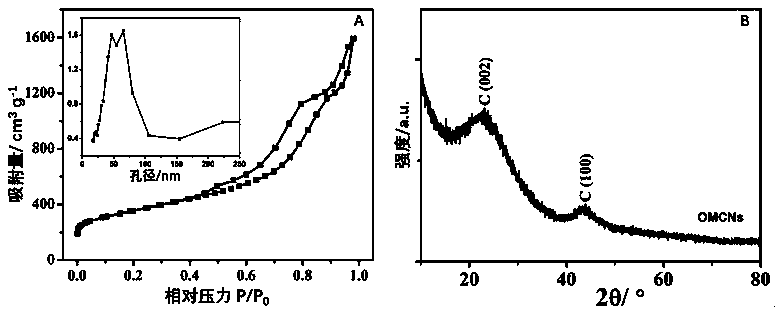

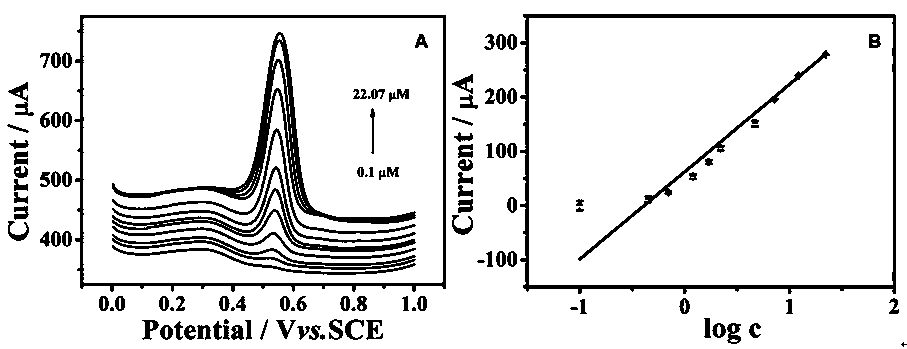

[0029] Preparation of materials: First, the collected crab shells were calcined in air at 350°C to remove organic protein and chitin, and then ground into powder in a mortar. Using the combination of hard template and surfactant self-assembly method, the calcined crab shell powder was impregnated in the ethanol solution of hot sol and triblock copolymer P123. The impregnated composites were evaporated at 25°C for 6 h, and then further thermally cured at 100°C for 24 h to obtain calcium carbonate / solsol / P123 composites. The obtained composite was heated at 350°C under nitrogen atmosphere with a heating rate of 1°C min -1 P123 template was removed by pyrolysis for 2 h. Then, the composite material was heated at 900°C under a nitrogen atmosphere, and the heating rate was 5°C min. -1 Pyrolysis for 2 h for further carbonization. Finally, the obtained calcium carbonate / carbon composite was treated with (6 M) hydrochloric acid solution as the calcium carbonate template. After was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com