Saccharification and yield-increase process for high-solubility beer

A high solubility, beer technology, applied in the direction of beer brewing, biochemical equipment and methods, wort preparation, etc., can solve the problems of reducing middle molecular peptides, low utilization rate of raw materials, malt can not be fully dissolved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

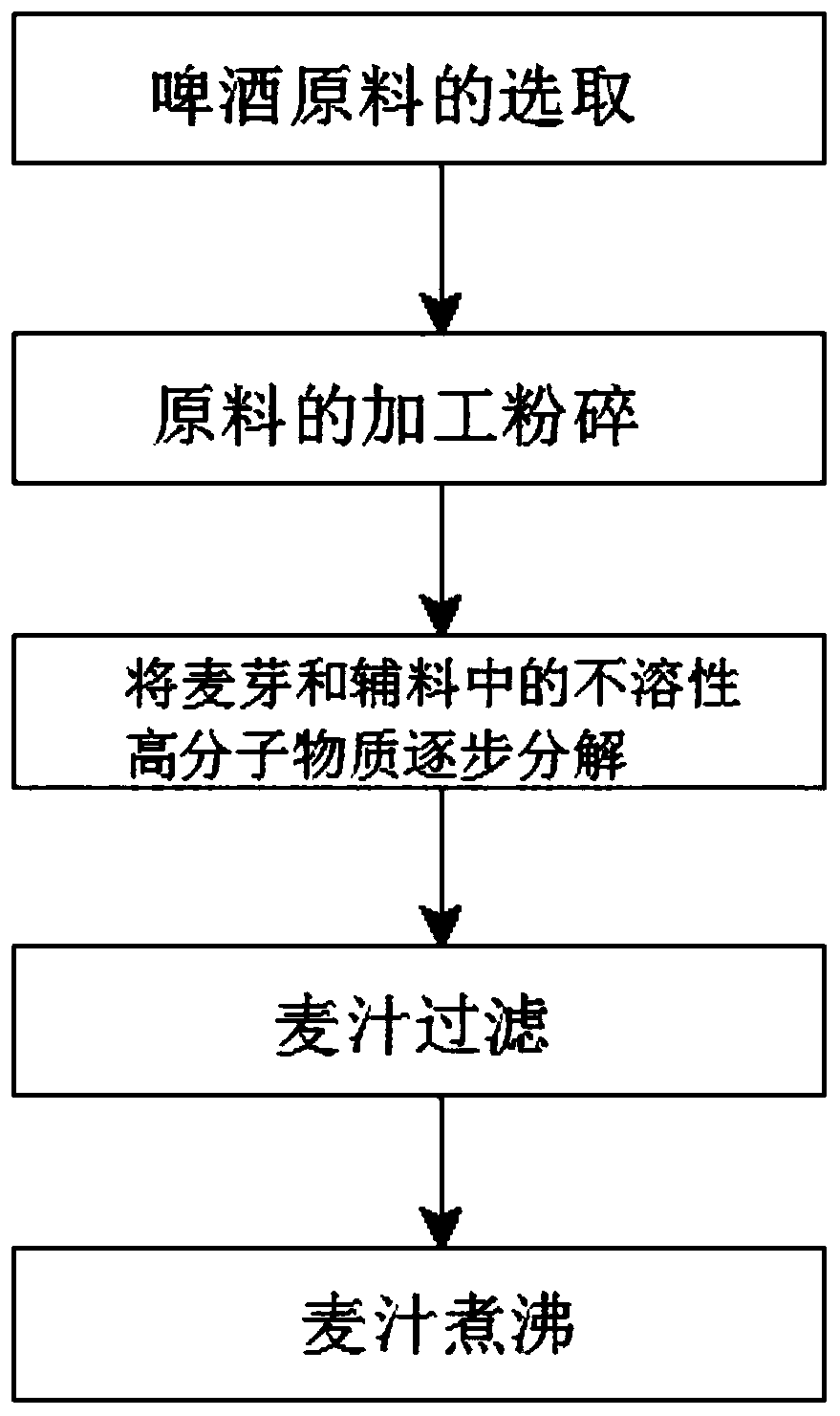

[0026] A high-solubility beer saccharification process for increasing production, comprising the following steps:

[0027] S1: Select the basic raw materials of beer water, malt, rice, hops and yeast;

[0028] S2: Processing of basic raw materials, crushing malt and rice;

[0029] S3: Saccharification is to use various hydrolytic enzymes contained in malt to gradually decompose insoluble high molecular substances in malt and auxiliary materials into soluble low molecular substances under suitable conditions (temperature, pH value, time);

[0030] S4: Wort filtration is a rapid and thorough separation of soluble extracts in mash, reducing wheat polyphenols, pigments, bitter substances and high molecular weight proteins, fatty acids and β-glucans in malt that affect beer flavor etc. into the wort, thus ensuring good taste and clarification of the wort;

[0031] S5: After the wort is boiled, put the boiled wort into the whirling sedimentation tank for 30-40 minutes to stand sti...

Embodiment approach 2

[0038] The operation of the top hot water in the wort filtration is to first check the filter tank, clean it, close the windshield, and check whether the pipeline valve is closed, and then inject hot water at 78°C from the bottom until it just submerges the filter plate, and then pass it into the mash Pump the mash to prevent oxygen absorption, and the time to pump the mash is 8-12 minutes. After pumping the mash, let it stand for 10-20 minutes and then carry out the reflux operation of the wort. At this time, the clear wort contains about 40mg of fatty acids / L, and the turbid wort is more than 10 times, and the time is about 10min.

[0039] Gelatinization of auxiliary material rice: crush the dried rice into rice flour and send it to the gelatinization pot, add appropriate high temperature-resistant а-amylase, gypsum powder and cold water in turn into the gelatinization pot, and heat up the gelatinization pot while stirring quickly After reaching 50°C and keeping it for 10 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com