A kind of roaster automatically discharges carbon block control system and method

An automatic discharge and control method technology, applied in the direction of furnace control devices, furnaces, furnace components, etc., can solve the problems of manpower and fuel waste, and achieve the effects of reducing labor intensity, reducing pollution, and reducing escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

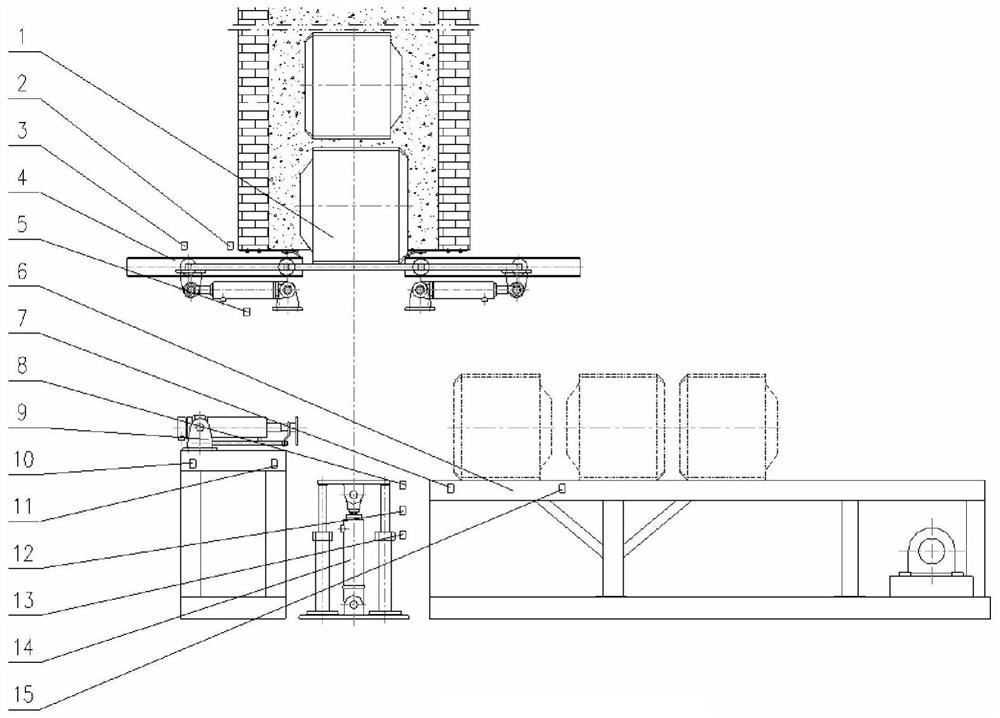

[0035] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

[0036] Such as figure 1 As shown, the control system for automatically discharging carbon blocks from the roaster of the present invention includes a furnace door mechanism 4, a conveyor 6, a pusher 9, a lift 14 and a control unit, wherein the furnace door mechanism 4 is installed at the bottom of the carbon block discharge port of the roaster, The lifter 14 is set under the furnace door mechanism 4 and directly below the carbon block outlet, the conveyor 6 is set on one side of the lifter, and the pusher is set on the other side of the lifter; the control unit is collected and installed on the furnace door mechanism, conveyor, top Each limit switch signal of the pusher and the elevator outputs control commands to the actuators of the furnace door mechanism 4 , the conveyor 6 , the pusher 9 and the elevator 14 .

[0037] figure 1 A schematic diagr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com