Fuel cell activation method and method for preventing /improving membrane dryness

A fuel cell and activation method technology, which is applied in the field of MEA dry film, can solve the problems of dry film and reduce the operating efficiency of the stack, and achieve the effects of simple operation, performance recovery, and shortened activation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

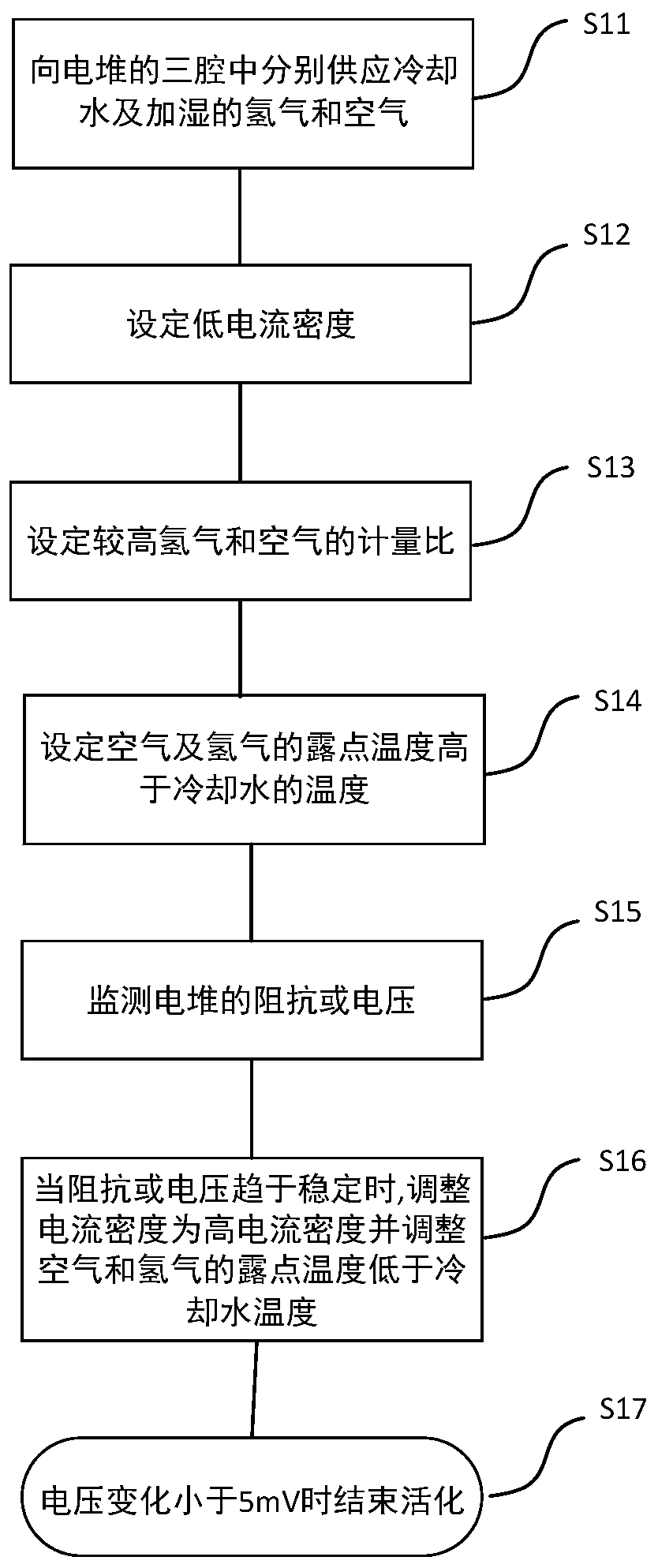

[0090] The hydrogen fuel cell stack was activated according to the conditions in Table 1 below.

[0091] Table 1: Stack activation conditions

[0092]

[0093] First, humidified hydrogen is provided to the anode of the stack and humidified air is provided to the cathode. Set the hydrogen metering ratio to 3 and the air metering ratio to 5. Set the first dew point temperature of air and hydrogen to 60°C, and the temperature of the cooling water for battery operation to 55°C. Keep the battery current stable at about 0.1A / cm 2 At low current density. Run for 30-60min under this condition.

[0094] At the same time, a high-frequency impedance meter is used for online measurement of the fuel cell stack.

[0095] When the measured value of resistance tends to no longer change, it is converted to 2A / cm 2 At the same time, adjust the dew point temperature of air and hydrogen to 45℃, and the cooling water temperature of the battery is 70℃. Continue to operate under high current density unt...

Embodiment 2

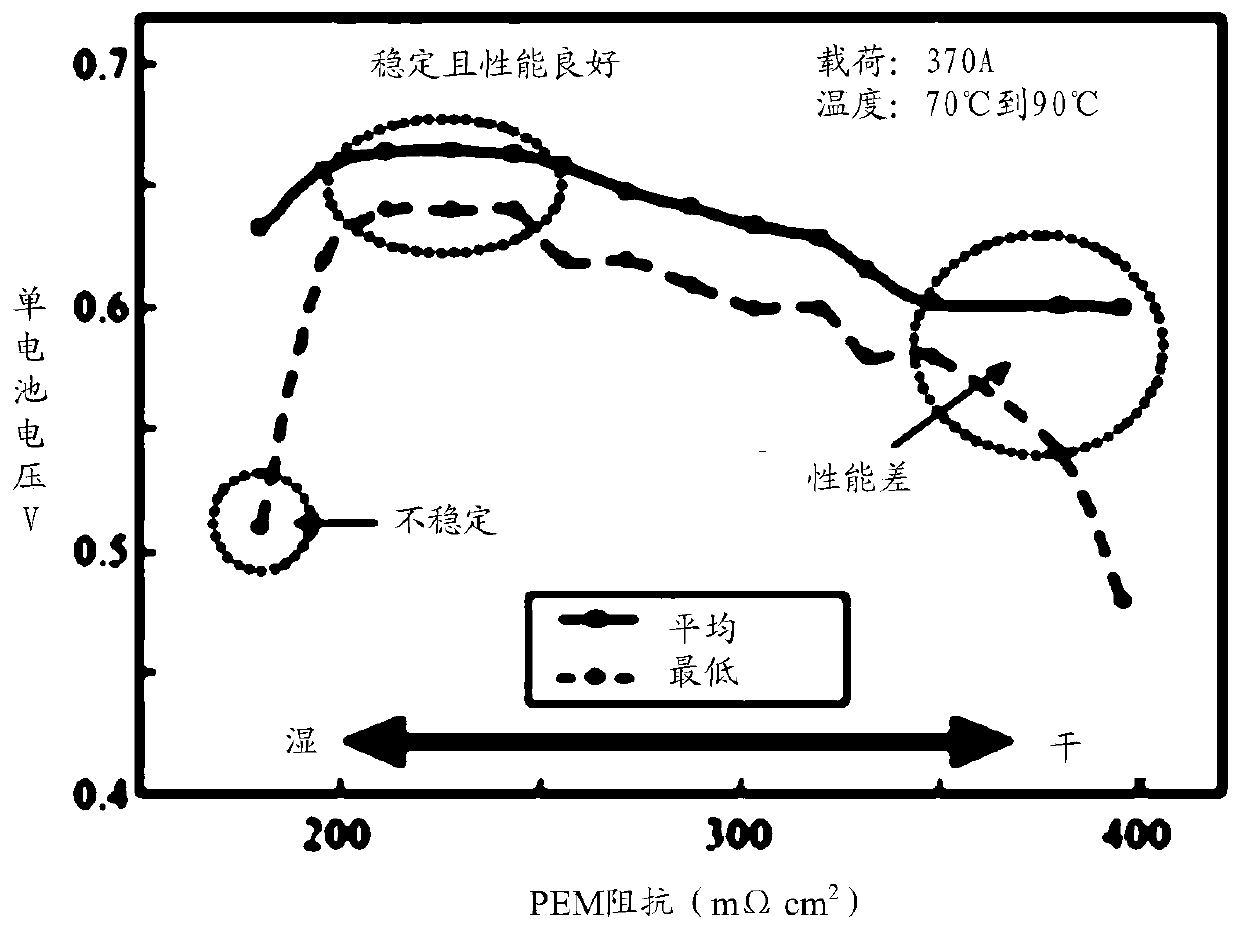

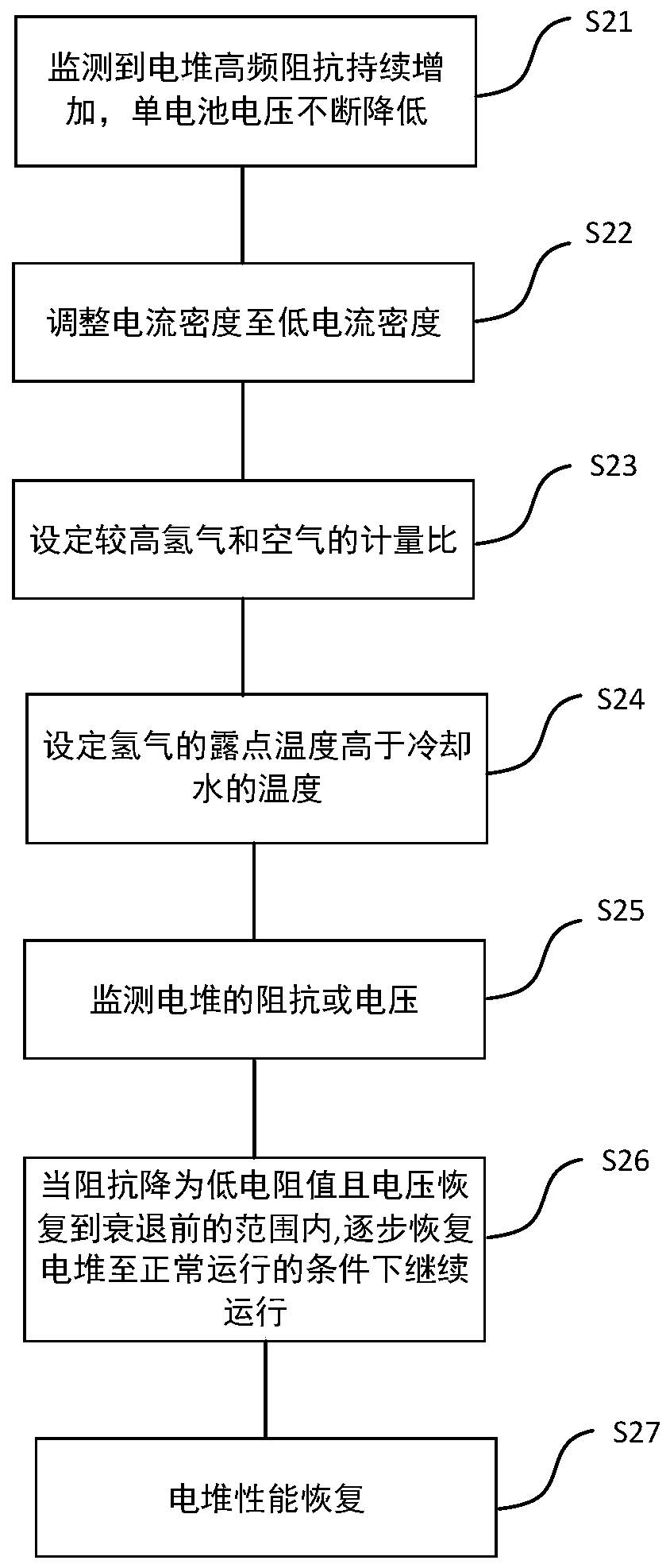

[0102] In the self-humidifying fuel cell stack, the current density is 2A / cm 2 , The cooling water temperature is 70-85 ℃ under the condition of normal operation. At this time, the dew point temperature of hydrogen is set at 45-55°C, the metering ratio of hydrogen is 1.25-1.3, and the metering ratio of air is 1.5-2. During the monitoring, the high-frequency resistance value is about 300mΩcm2 and the voltage is 0.6V.

[0103] When the resistance value is found to continue to rise> 350mΩcm2, while the voltage continues to drop 2 , And then adjust the stack temperature so that the cooling water temperature is 55°C and the hydrogen dew point is 60°C. And adjust the metering ratio of hydrogen to 2.2, and the metering ratio of air to 2.0.

[0104] Observe that the resistance value begins to decrease, and the voltage begins to increase. Run for 30-60 minutes under this low current density condition until the voltage returns to 0.845V and the voltage fluctuation range is less than 5mV.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com