Preparation method for novel material layer structure of high-frequency circuit board and product thereof

A new type of board and material layer technology, applied in the direction of circuit substrate materials, printed circuit manufacturing, printed circuits, etc., can solve the problem of difficult signal transmission frequency and speed of circuit boards, increased power consumption and signal transmission loss, dielectric constant and Problems such as large loss factor, to achieve the effect of shortening product processing time, improving product performance, and speeding up transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

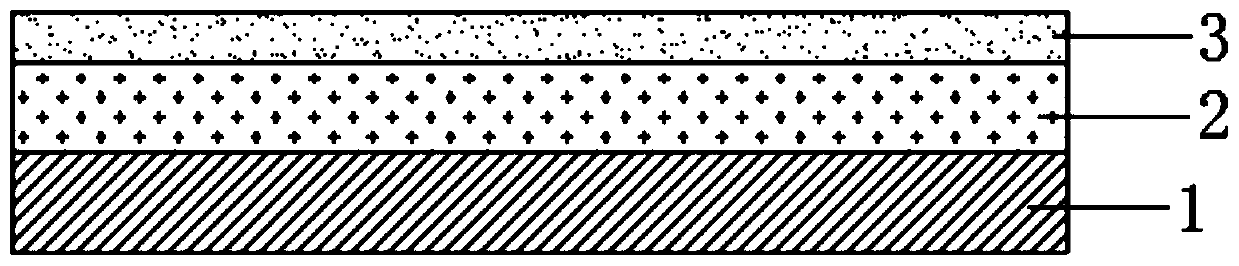

[0027] An embodiment of the present invention provides a method for preparing a new material layer structure of a high-frequency circuit board, including the following steps:

[0028] (1) coating one deck synthetic liquid TFP film on the solidified PI film front;

[0029] (2) Send the cured PI film coated with the synthetic liquid TFP film to the tunnel oven as a whole, and pass through several heating and baking areas in the tunnel oven in sequence at a speed of 0.5-20m / s for segmental baking , forming a semi-cured TFP film on the front side of the cured PI film;

[0030] (3) Copper foil is hot-pressed on the semi-cured TFP film to obtain a new material layer structure on one side of the high-frequency circuit board.

[0031] In the step (2), the several heating and baking zones in the tunnel oven at least include a heating and baking zone, a second heating and baking zone, a third heating and baking zone, and a fourth heating and baking zone , Five-stage heating and baking...

Embodiment 2

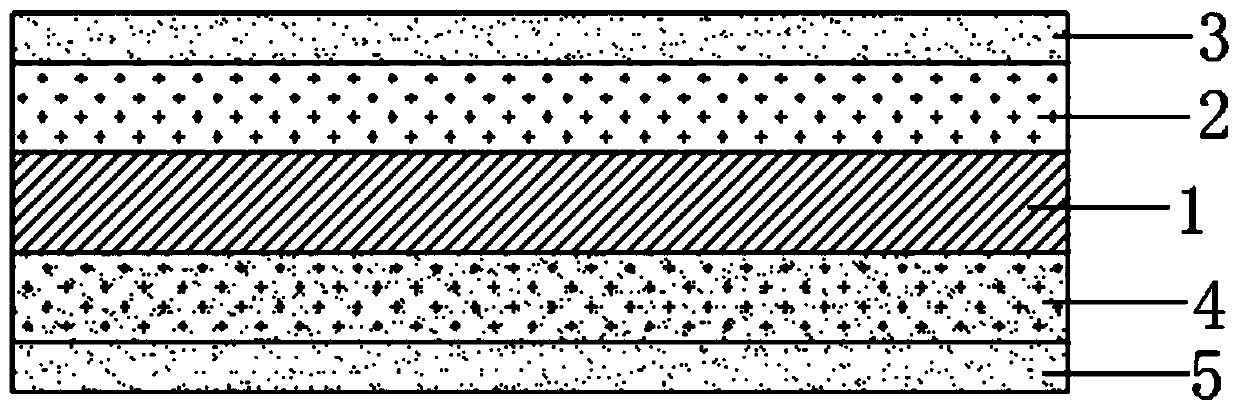

[0050] The main difference between this embodiment and Embodiment 1 is:

[0051] The step (1) also includes the following steps: coating a layer of synthetic liquid TFP film on the back side of the solidified PI film; after step (2), a semi-cured TFP film is formed on the front and back sides of the solidified PI film; After (3), a double-sided new material layer structure of the high-frequency circuit board is obtained.

[0052] Therefore, the double-sided new material layer structure of the high-frequency circuit board can be prepared by the above method, such as figure 2 As shown, a lower semi-cured TFP film 4 is coated on the back of the cured PI film 1, and a lower copper foil layer 5 is pressed on the lower surface of the lower semi-cured TFP film 4 to form a double-sided new material for high-frequency circuit boards. layer structure. Specifically, after the lower copper foil layer 5 is pressed onto the lower semi-cured TFP film 4 , the lower semi-cured TFP film 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com