A new high-concentration powder carrier biological fluidized bed process for treating urban sewage

A technology of biological fluidized bed and urban sewage, applied in the field of high-concentration powder carrier biological fluidized bed process, can solve the problems of unavoidable secondary lifting, lengthy treatment process, and many treatment units, so as to improve the utilization rate of dissolved oxygen, Enhance convective mass transfer and avoid deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

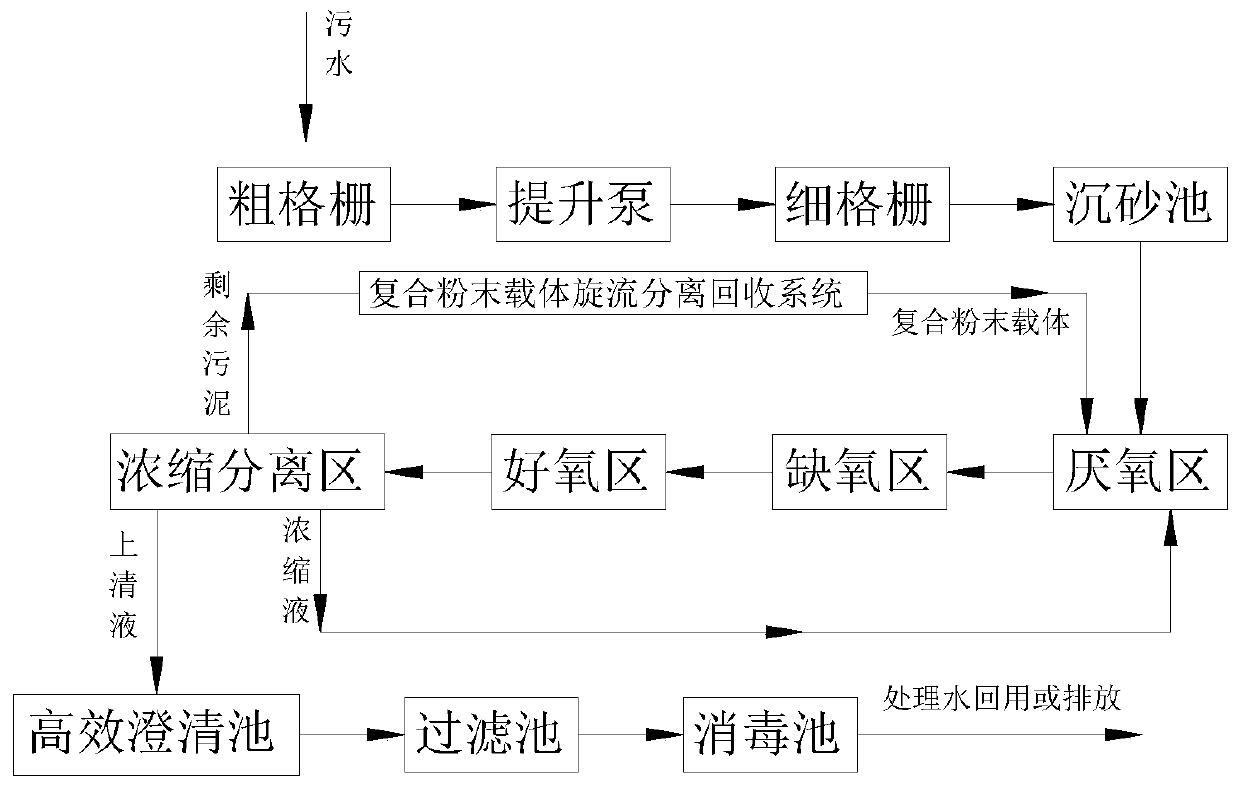

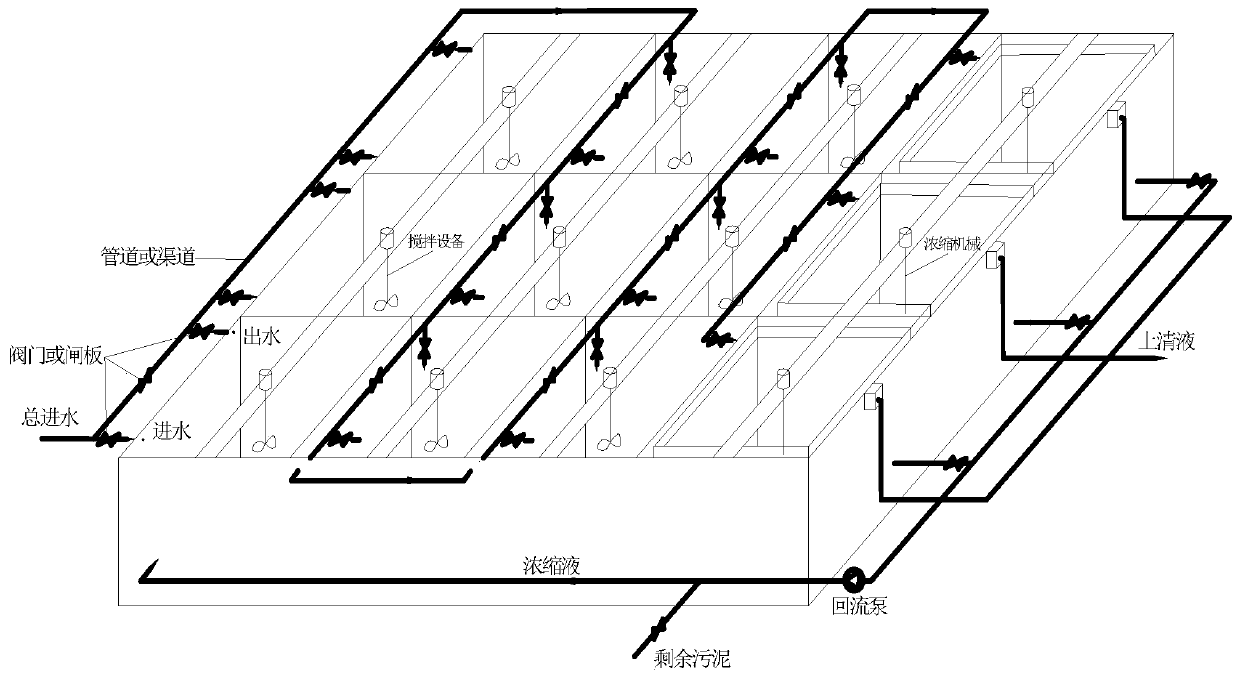

[0034] Combine below figure 1 with figure 2 The present invention is described in detail, and the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

[0035] The invention provides a new high-concentration powder carrier biological fluidized bed process for treating urban sewage. The process is as follows: the sewage first passes through the coarse grid (that is, the channel system) and the lifting pump, and is lifted to the fine grid and sand settling. pool, and then into the HPB biochemical pool. The HPB biochemical pool includes four functional areas: Anaerobic / Anoxic / Oxic / Concentrated, referred to as A 2 / O / C), respectively add composite powder carriers to the anaerobic zone, anoxic zone, and aerobic zone, and stir and mix to form a mixed solution, concentrate and separate the above mixed solution flowing into the concentrated separation zone, and return the concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com