A kind of aluminum borate whisker and its preparation method and application

A technology of aluminum borate whiskers and preparation steps, applied in the field of ceramic materials, can solve problems such as difficult operation, and achieve the effects of high purity, good crystallinity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Using aluminum chloride hydrate and urea as raw materials, set the molar ratio of urea / aluminum chloride to 6:1, weigh 1g (0.0041mol) of aluminum chloride hydrate and 1.49g (0.0249mol) of urea, and mix aluminum chloride (AlCl 3 ·6H 2 O, 99.99%) and urea (CO(NH 2 ) 2 , 99.5%) were respectively dissolved in 20ml of alcohol solvent, after being completely dissolved, the urea solution was added to the aluminum chloride solution while stirring to obtain a clear and transparent stable precursor salt solution, which was continuously stirred at a constant temperature (80°C) until the solution was 10ml to obtain a stable precursor salt solution with an aluminum ion concentration of 0.4142mol / L;

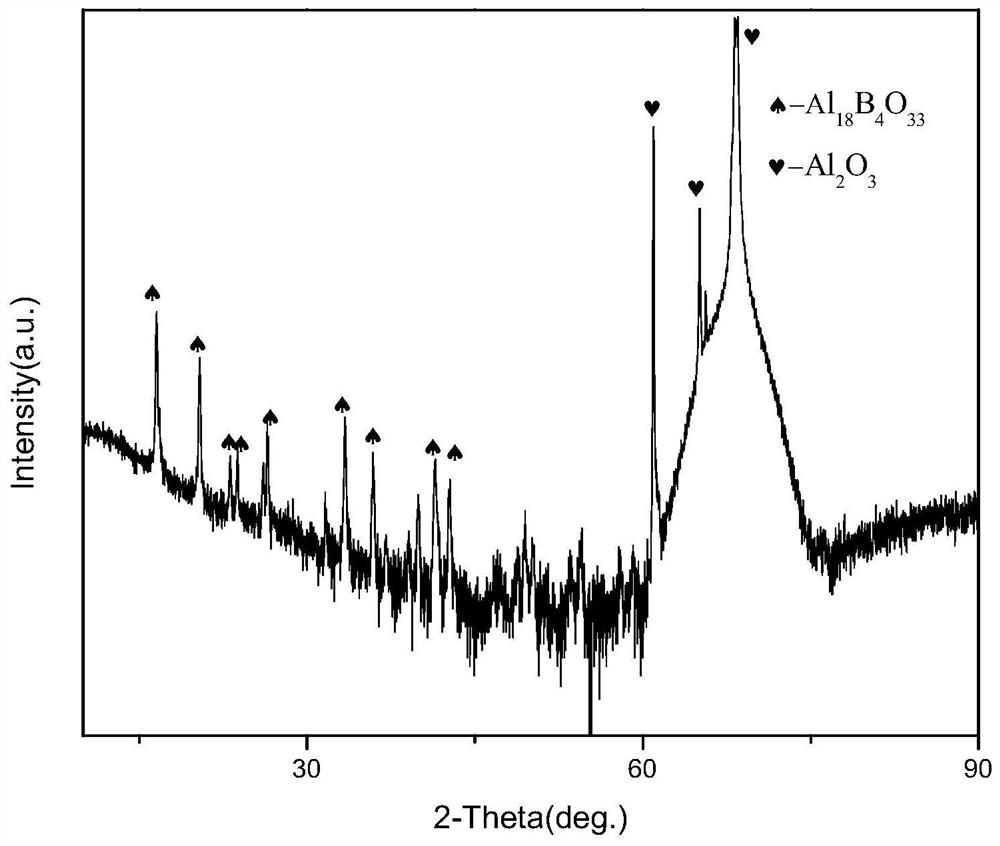

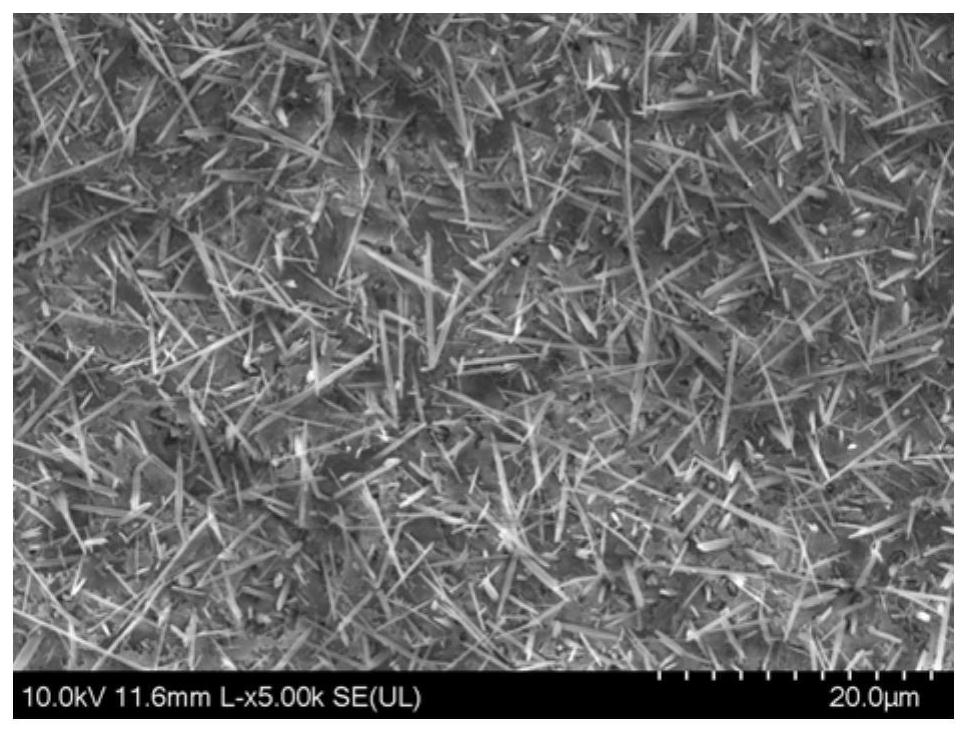

[0034] 2. Coat the concentrated precursor salt solution on the alumina substrate, put it into a boron nitride crucible, and raise the temperature to 1000°C at a rate of 10°C / min under the protection of nitrogen (atmosphere flow rate of 0.4L / min), and keep it warm 5h, aluminum bor...

Embodiment 2

[0036] 1. Using aluminum chloride hydrate and urea as raw materials, set the molar ratio of urea / aluminum chloride to 6:1, weigh 1g (0.0041mol) of aluminum chloride hydrate and 1.49g (0.0249mol) of urea, and mix aluminum chloride (AlCl 3 ·6H 2 O, 99.99%) and urea (CO(NH 2 ) 2 , 99.5%) were respectively dissolved in 20ml of alcohol solvent, after being completely dissolved, the urea solution was added to the aluminum chloride solution while stirring to obtain a clear and transparent stable precursor salt solution, which was continuously stirred at a constant temperature (80°C) until the solution was 10ml to obtain a stable precursor salt solution with an aluminum ion concentration of 0.4142mol / L;

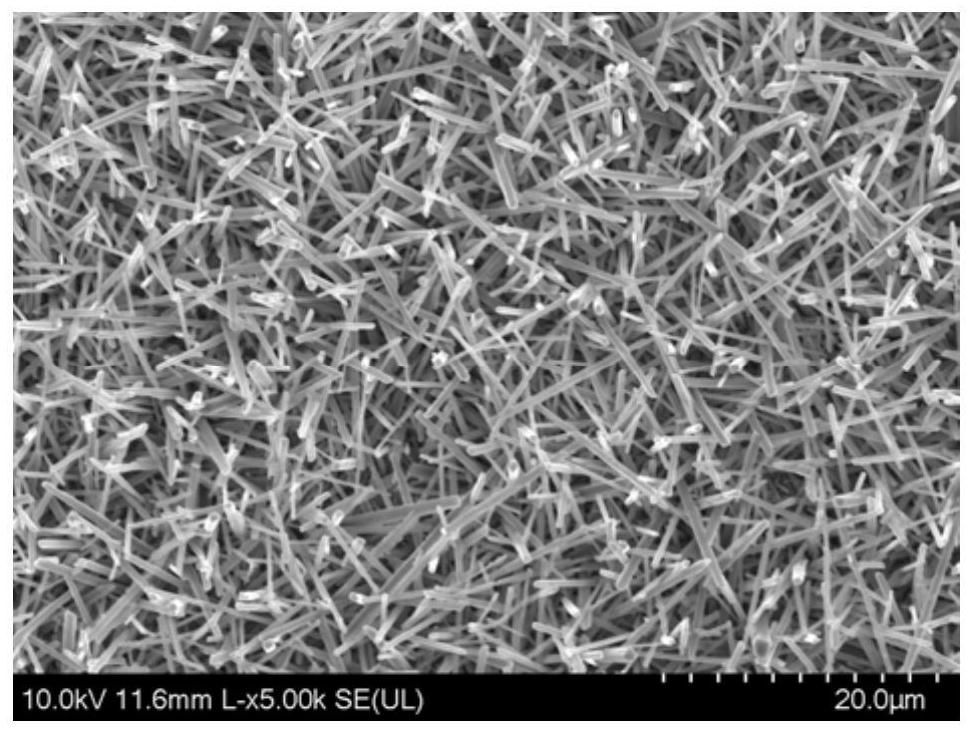

[0037] 2. Coat the concentrated precursor salt solution on the alumina substrate, put it into a boron nitride crucible, and raise the temperature to 1200°C at a rate of 10°C / min under nitrogen protection (atmosphere flow rate of 0.4L / min), and keep it warm 5h, aluminum borate whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com