Preparation method of porous carbon coated aluminum foil material for lithium ion battery

A lithium-ion battery and aluminum foil technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of reducing material strength, poor physical properties of aluminum foil, poor adhesion of aluminum foil, etc., to improve process capability, increase battery energy density, The effect of increasing the design capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

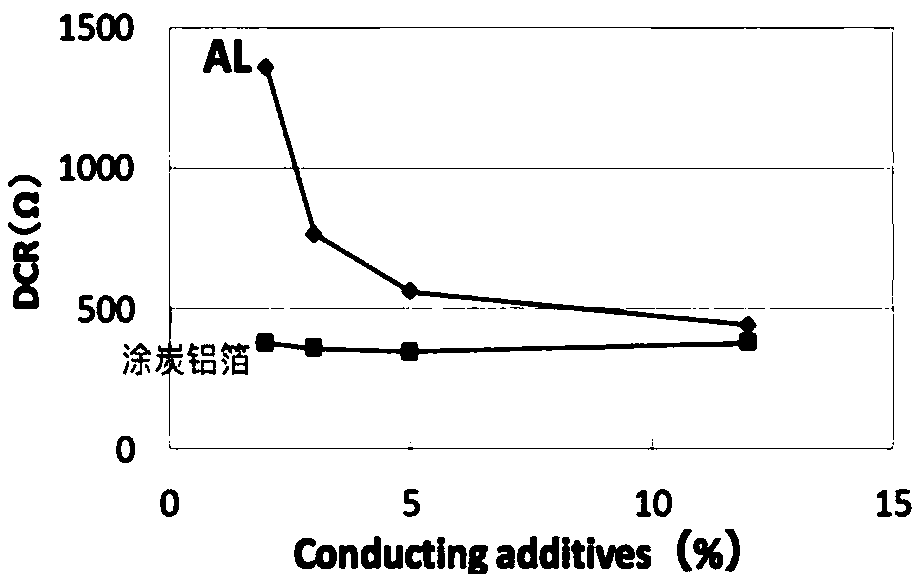

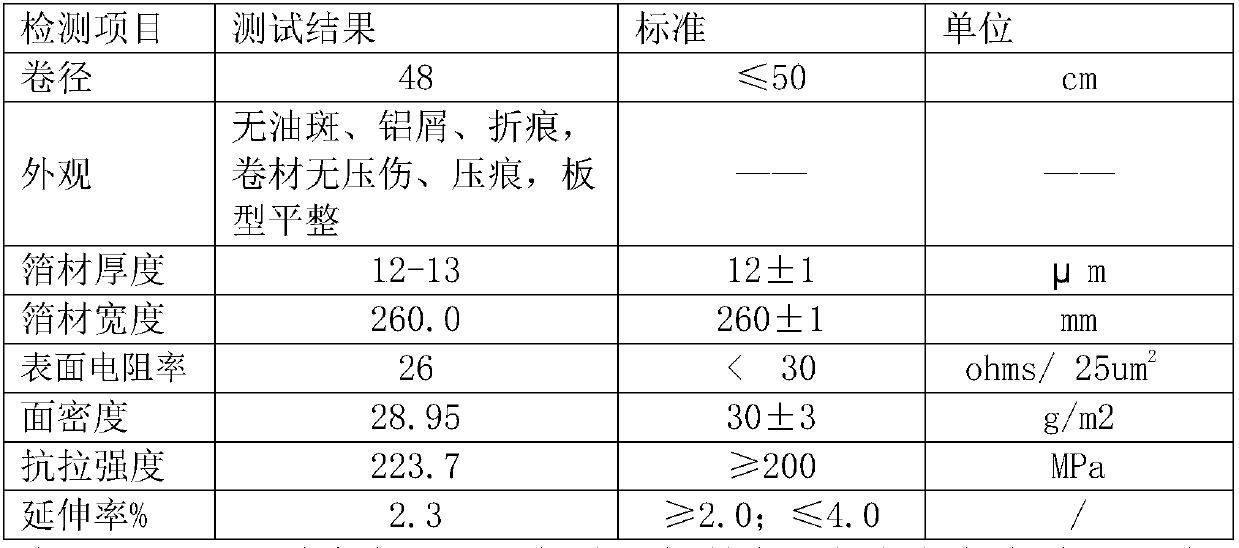

[0032] Embodiment 1 of the present invention provides a preparation method of a porous carbon-coated aluminum foil material for a lithium-ion battery, which is achieved through the following steps:

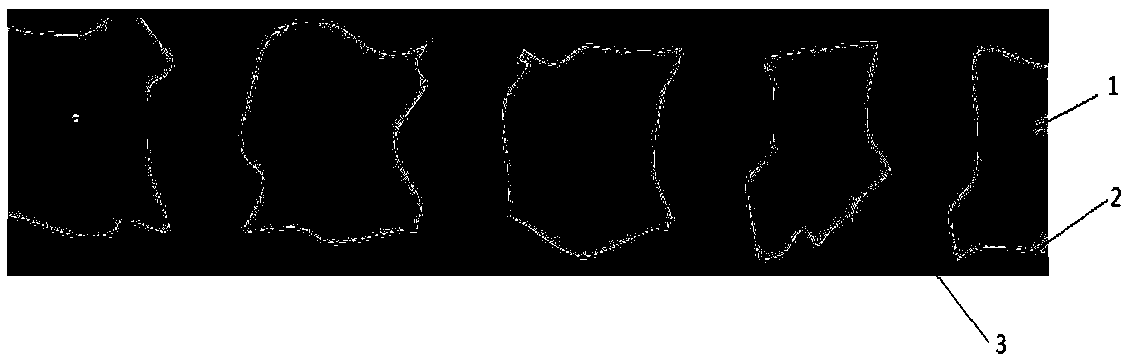

[0033] (1) With the inert electrode as the cathode and the aluminum foil as the anode, the aluminum foil is dragged by rollers through the electrolytic cell for direct current electrolysis. The inert graphite cathode is a graphite plate, and the electrolytic cell is provided with a mixed solution of hydrochloric acid and potassium chloride at a temperature of 30° C., wherein the concentration of the hydrochloric acid is 1mol / L, and the concentration of potassium chloride is 2mol / L. Solution current density is 0.5A / cm 2 , and the time is 12 minutes; the treated aluminum foil is washed with industrial deionized water and wound up to obtain an aluminum foil coil.

[0034] (2) The treated aluminum foil coil is put into a vacuum heat treatment furnace and heated to 240-300°C with the ...

Embodiment 2

[0038] Embodiment 2 of the present invention provides a preparation method of a porous carbon-coated aluminum foil material for a lithium-ion battery, which is achieved through the following steps:

[0039] (1) With the inert electrode as the cathode and the aluminum foil as the anode, the aluminum foil is dragged by rollers through the electrolytic cell in sequence for DC electrolysis. The inert graphite cathode is a graphite flat plate, and the electrolytic cell is provided with a mixed solution of hydrochloric acid and potassium chloride at a temperature of 30° C., wherein the concentration of the hydrochloric acid is 5mol / L, and the concentration of potassium chloride is 3mol / L. Solution current density is 0.8A / cm 2 , the time is 4min. Then, the above-mentioned treated aluminum foil is washed with industrial deionized water and wound up to obtain an aluminum foil coil.

[0040] (2) The treated aluminum foil coil is put into a vacuum heat treatment furnace and heated to 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com