Metal Bipolar Plates of Proton Exchange Membrane Fuel Cells with Non-adhesive Sealing Structure

A metal bipolar plate, proton exchange membrane technology, used in fuel cell parts, fuel cells, sealing/supporting devices, etc. The bonding process is complicated and the corrosion resistance is affected, so as to achieve the effect of easy batch production, overcoming the long processing cycle and improving the pressure resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

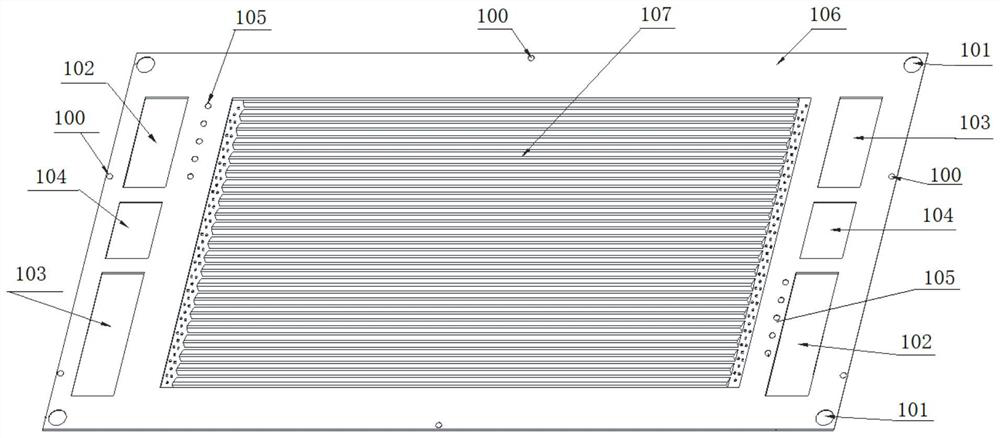

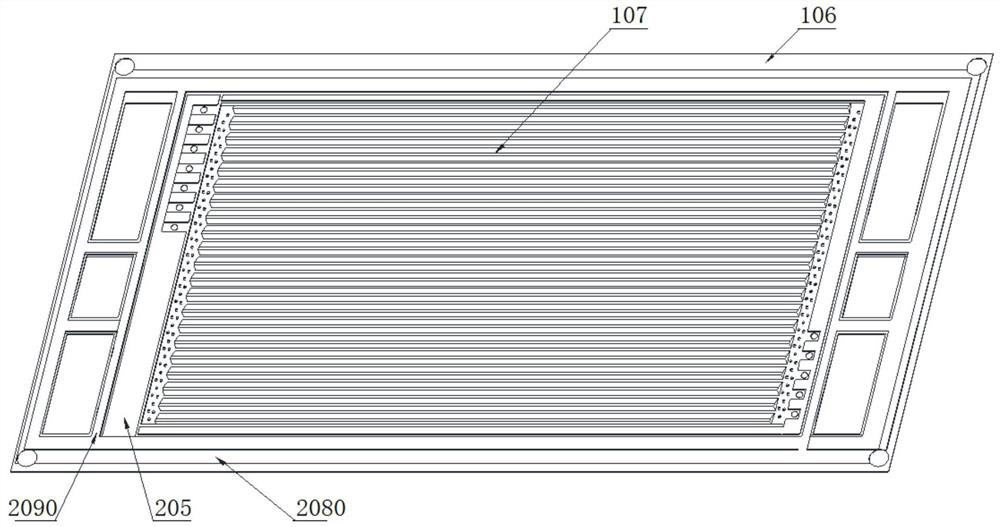

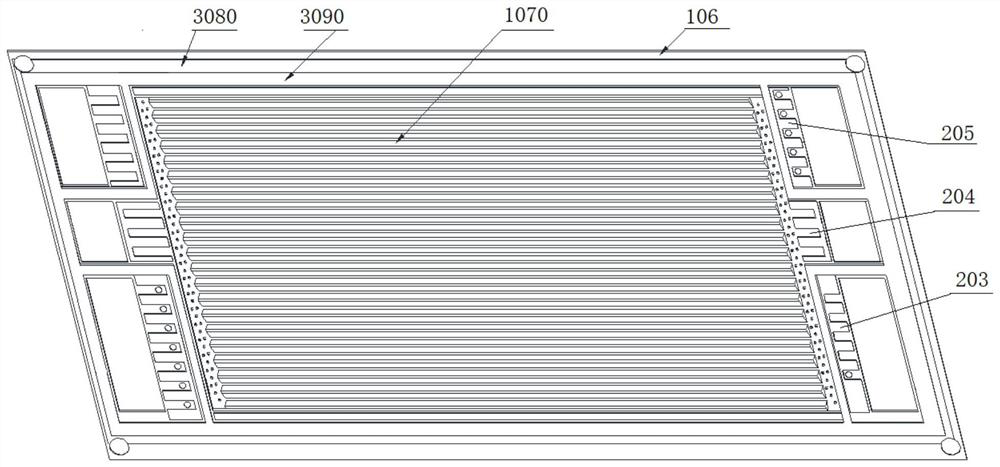

[0035] The principle of the present invention is that two kinds of hardness rubber materials A rubber and B rubber are injected into the metal plates of the anode plate 1 and the cathode plate 2 respectively to form a sealing structure to realize the sealing and channel functions, and the A rubber material with low hardness has a specific hardness after curing. The high B rubber material is thick, and the B rubber with high hardness acts as a channel. The low hardness sealing ring is pressed by the fuel cell assembly force, and the cathode cavity, anode cavity and coolant cavity of the metal bipolar plate are sealed by using the compression elasticity of the low hardness A rubber material. Sealing, the coolant chamber is sealed by the rubber sealing ring opposite to the anode plate 1 and the cathode plate 2 through rubber compression elasticity.

[0036] The present invention will be further described below in conjunction with drawings and embodiments.

[0037] The bipolar pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com