Wear-resistant flame-retardant sole rubber for forest fire-fighting shoes, and preparation method thereof

A technology for firefighting and footwear, applied in soles, applications, footwear, etc., can solve the problems of rubber shoes not durable, low application range, limited flame retardant ability, etc. The effect of flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

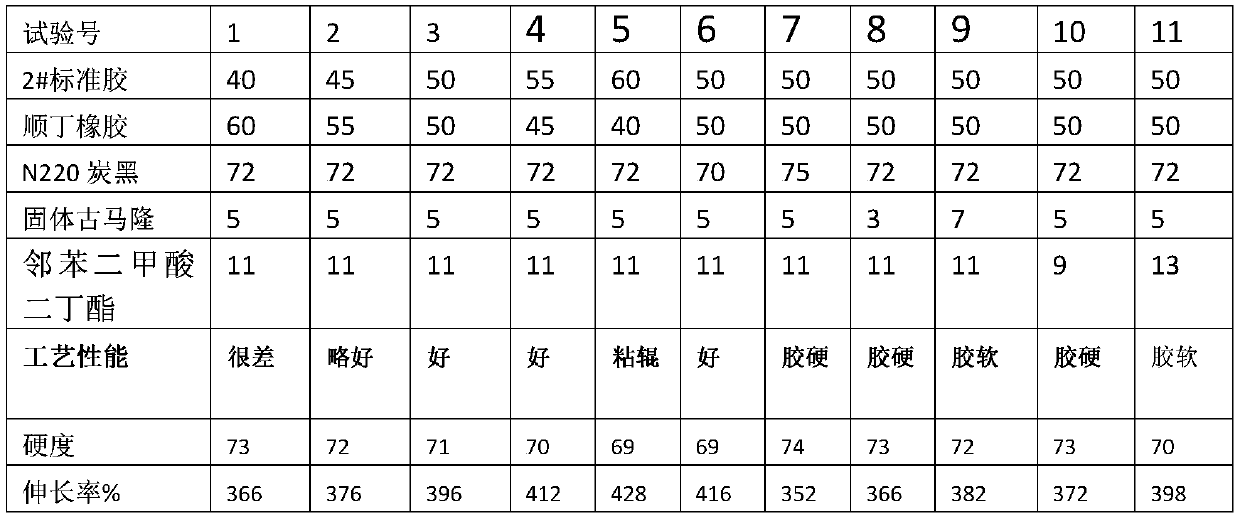

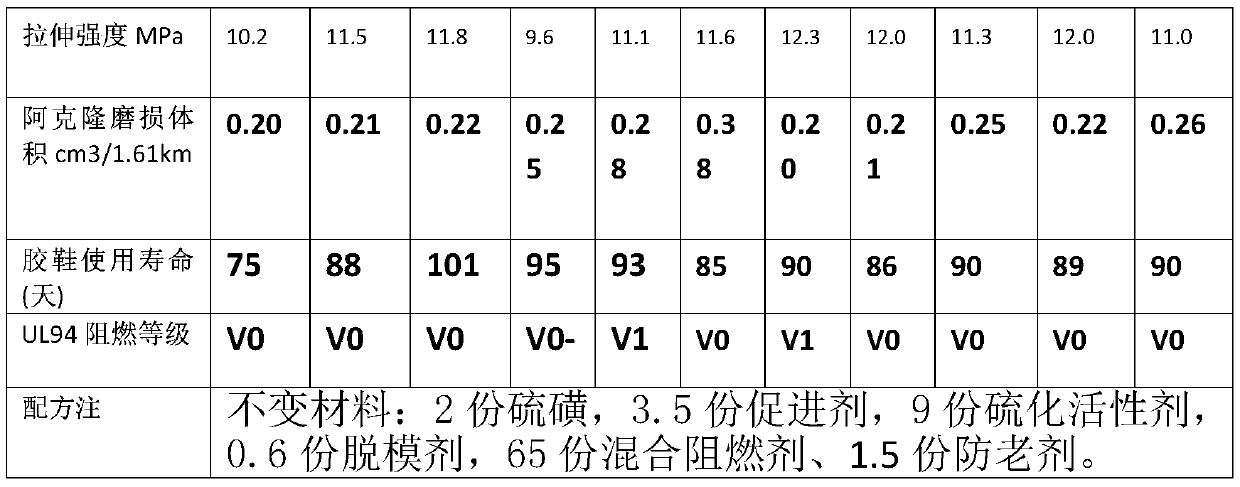

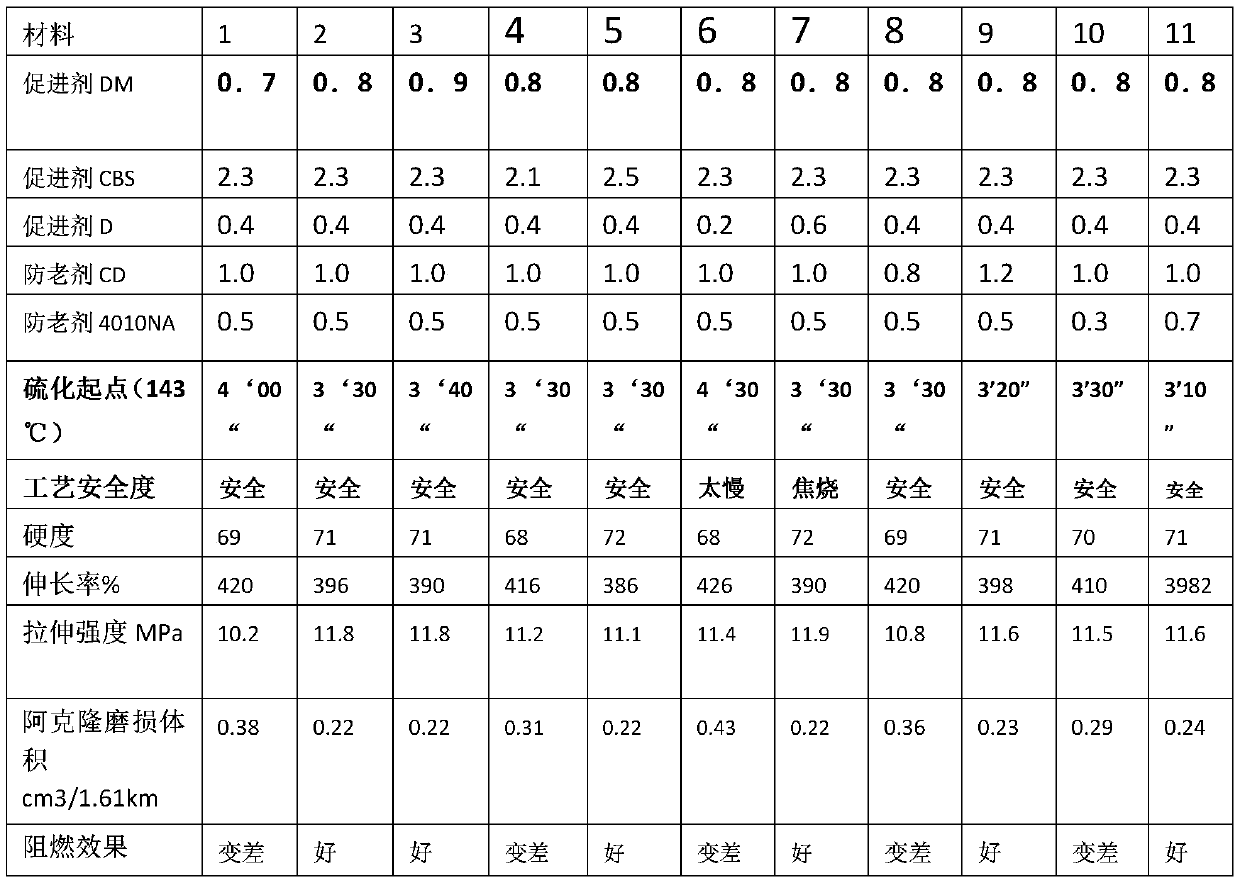

[0057] Embodiment 1 of the present invention: wear-resistant flame-retardant sole rubber for forest fire-fighting shoes, calculated in parts by weight, it includes 50 parts of 2# standard glue, 50 parts of synthetic rubber (using butadiene rubber), 2 parts of sulfur, 3.5 parts Part accelerator (3.5 parts of accelerator is composed of 0.8 parts of accelerator DM, 2.3 parts of accelerator CBS and 0.4 part of accelerator D), 9 parts of vulcanization activator (every 9 parts of vulcanization activator is 3 parts of tertiary stearic acid And 5 parts of nano zinc oxide, 1 part of light magnesium oxide), 0.6 parts of release agent, 72 parts of carbon black, 16 parts of softener (every 16 parts of softener consists of 11 parts of dibutyl phthalate and 5 parts solid coumarone), 65 parts of mixed flame retardant (each 65 parts of mixed flame retardant consists of 20 parts of decabromodiphenyl ether and 10 parts of antimony oxide, 20 parts of chlorinated paraffin (-70), 15 parts of zinc b...

Embodiment 2

[0060] Embodiment 2 of the present invention: wear-resistant type flame-retardant sole rubber for forest fire-fighting shoes, calculated by weight, it includes 55 parts of 2# standard glue, 45 parts of synthetic glue (using butadiene rubber), 2 parts of sulfur, 3.5 parts Part accelerator (3.5 parts of accelerator is composed of 0.8 parts of accelerator DM, 2.3 parts of accelerator CBS and 0.4 part of accelerator D), 8.5 parts of vulcanization activator (every 8.5 parts of vulcanization activator is 3 parts of tertiary stearic acid And 4.5 parts of nano-zinc oxide, 1 part of light magnesium oxide), 0.6 part of release agent, 71 parts of N220 carbon black, 16 parts of softener (every 16 parts of softener consists of 11 parts of dibutyl phthalate and 5 65 parts of mixed flame retardant (each 65 parts of mixed flame retardant consists of 20 parts of decabromodiphenyl ether and 10 parts of antimony oxide, 20 parts of chlorinated paraffin (-70), 15 parts of zinc borate composition),...

Embodiment 3

[0063] Embodiment 3 of the present invention: forest fire-fighting shoes wear-resistant type flame-retardant sole rubber, calculated in parts by weight, it includes 52 parts of 2# standard glue, 48 parts of synthetic rubber (using butadiene rubber), 2 parts of sulfur, 3.5 parts Part accelerator (3.5 parts of accelerator is composed of 0.8 parts of accelerator DM, 2.3 parts of accelerator CBS and 0.4 parts of accelerator D), 8.0 parts of vulcanization activator (every 8.5 parts of vulcanization activator is 2.5 parts of tertiary stearic acid And 4.5 parts of nano-zinc oxide, 1 part of light magnesium oxide), 0.6 part of release agent, 73 parts of N220 carbon black, 16 parts of softener (every 16 parts of softener consists of 11 parts of dibutyl phthalate and 5 65 parts of mixed flame retardant (each 65 parts of mixed flame retardant consists of 20 parts of decabromodiphenyl ether and 10 parts of antimony oxide, 20 parts of chlorinated paraffin (-70), 15 parts of zinc borate com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com