Disulfide bond and hydrogen bond-containing double self-repairing polyurethane coating for invisible car clothing and preparation method thereof

A polyurethane coating and disulfide bond technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of low self-repair efficiency and single self-repair mode, and achieve fast repair speed, high strength and repair efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

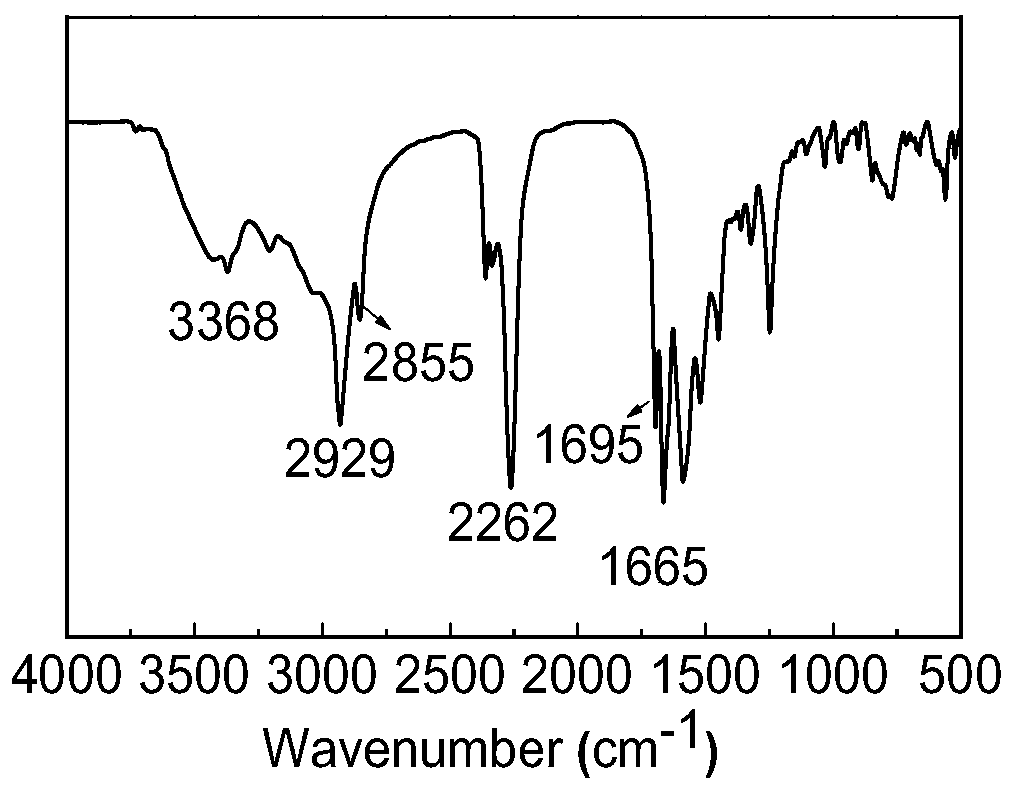

[0052] Add 1 part of 2-amino-6methyl-4-[3H]pyrimidinone and 10 parts of HMDI into a 250ml three-neck flask, under the protection of inert gas, react at 60°C for 72h, cool to 40°C after the reaction stops, and use 300ml Wash 2 times with dry n-hexane to remove unreacted HMDI, and dry in vacuum at 50°C overnight to obtain white powder 2-(6-isocyanate)-6-methyl-4[3H]-pyrimidinone (UPy-NCO) single-ended Isocyanate-based intermediate in 92% yield.

Embodiment 2

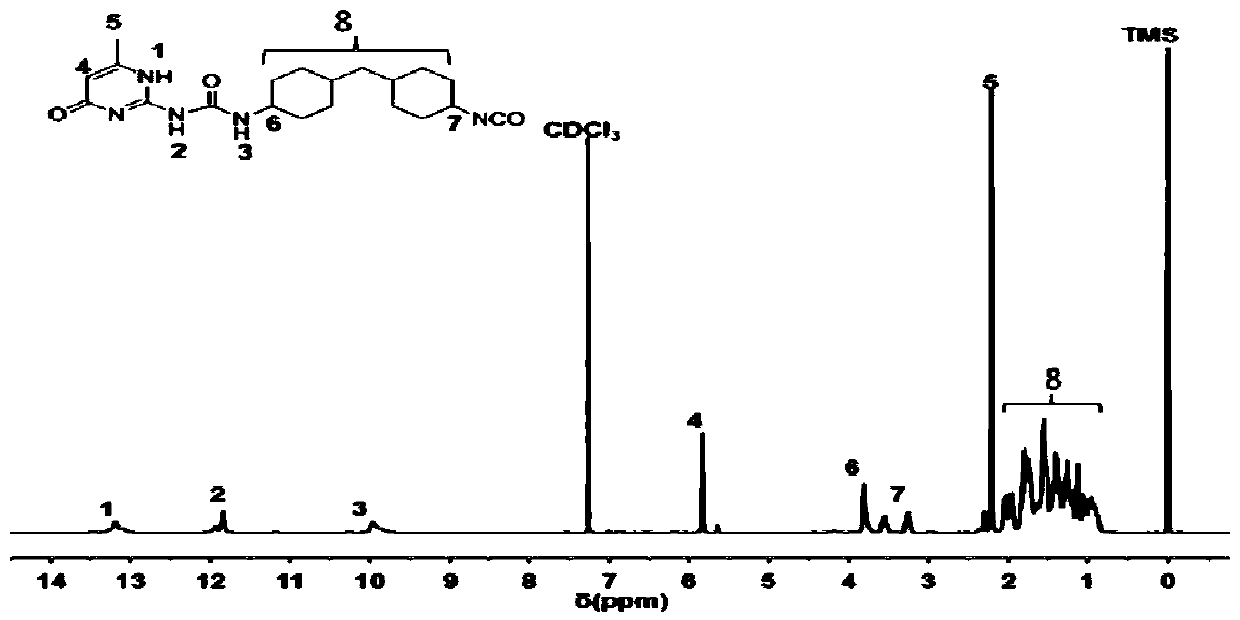

[0054] Mix 1 part of 2-(6-isocyanate)-6-methyl-4[3H]-pyridone with 3 parts of 2-amino-2-methyl-1,3-propanediol, 50ml of dry CHCl 3 Add it into a 100ml three-necked flask, and react at 90°C for 10h under the protection of an inert gas. After the reaction was completed, filter and wash with 30ml of dry CHCl 3 After washing 2 times, the crude product was dissolved in DMF to obtain a cloudy solution. The cloudy solution was then centrifuged to obtain a supernatant. The supernatant was precipitated in excess ether to obtain a white product, which was filtered and washed several times with acetone, and vacuum-dried at 50°C for 4 hours to obtain a white powder (UPy-diol) containing multiple hydrogen bond chain extender B with a yield of 78%.

Embodiment 3

[0056] Weigh 1 part of hydroxyl-terminated polybutadiene (Krasol TM LBH-2000), 3 parts of toluene diisocyanate (TDI), dissolved in THF, reacted at 80°C for 3.5h. 1 part of bis(2-hydroxyethyl) disulfide and 1 part of UPy-diol prepared in Example 2 were added to DMF, and the reaction was continued at 85°C for 5 hours. After pouring into the mold overnight to evaporate the solvent, put it in an oven at 80°C for 24 hours, and dry it in a vacuum at 70°C for 24 hours to obtain a double self-healing polyurethane film of disulfide bond and hydrogen bond.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com