Organic matter microcarbonization treatment equipment and process

A technology for processing equipment and organic matter, used in the petroleum industry, special forms of dry distillation, coke ovens, etc., can solve the problems of incompatibility with waste treatment equipment, low waste treatment efficiency, and poor carbonization treatment effect, achieving low inertia and heat. The effect of small loss and uniform heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

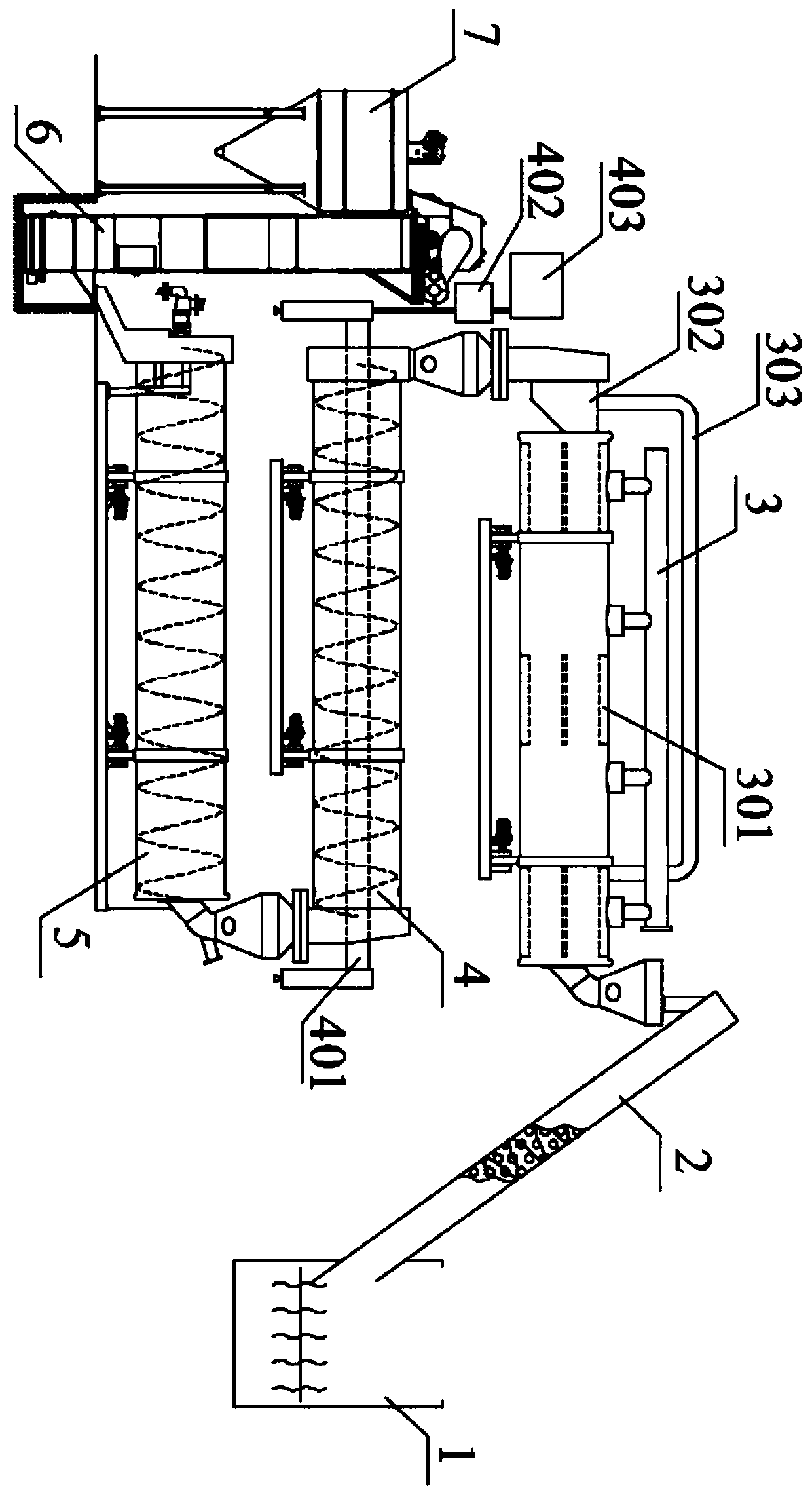

[0029] Such as figure 1 As shown, a micro-carbonization treatment equipment for organic matter includes a feeding pool 1, a feeding auger 2, a drying furnace 3, a micro-carbonization furnace 4, a slag cooler 5, a bucket elevator 6 and an ash bin 7, and a feeding pool One side of 1 is provided with a feeding auger 2, the inlet of the feeding auger 2 is connected with the feeding pool 1, the outlet of the feeding auger 2 is connected with the inlet of the drying furnace 3, and the drying furnace The discharge port of 3 is connected with the feed port of micro-carbonization furnace 4, the discharge port of micro-carbonization furnace 4 is connected with the feed port of slag cooler 5, and the discharge port of slag cooler 5 is connected with the feed port of bucket elevator 6. The feed port is connected, and the discharge port of the bucket elevator 6 is connected with the feed port of the ash bin 7.

[0030] An electric sieve is arranged inside the feeding tank 1, and the sieve...

Embodiment 2

[0036] A process for micro-carbonizing organic matter using the micro-carbonization treatment equipment for organic matter in Embodiment 1, comprising the following steps:

[0037] S1. The organic raw materials are put into the feeding pool 1. After being filtered by the electric sieve, the organic raw materials enter the feeding port of the drying furnace 3 through the feeding auger 2, and then enter the drying furnace 3;

[0038]S2. The organic raw materials enter the drying furnace 3, and the organic raw materials are transported to the discharge port in the drying furnace 3. The microwave heating device on the wall of the drying furnace 3 is turned on, and the drying temperature is controlled at 120 ° C. The organic raw materials are dried to produce The water vapor and other harmful gases are discharged from the top exhaust hole, and the combustible gas is collected after being treated by the dust removal and desulfurization equipment. The dried organic matter is discharge...

Embodiment 3

[0042] A process for micro-carbonizing organic matter using the micro-carbonization treatment equipment for organic matter in Embodiment 1, comprising the following steps:

[0043] S1. The organic raw materials are put into the feeding pool 1. After being filtered by the electric sieve, the organic raw materials enter the feeding port of the drying furnace 3 through the feeding auger 2, and then enter the drying furnace 3;

[0044] S2. The organic raw material enters the drying furnace 3, and the organic raw material is transported to the discharge port in the drying furnace 3. The microwave heating device on the wall of the drying furnace 3 is turned on, and the drying temperature is controlled to be 140°C. The organic raw material is dried to produce The water vapor and other harmful gases are discharged from the top exhaust hole, and the combustible gas is collected after being treated by the dust removal and desulfurization equipment. The dried organic matter is discharged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com