High-strength fire-resistant anti-seismic steel bars and production method

A technology of anti-seismic steel bars and production methods, which is applied in the field of high-strength steel bar production, can solve problems such as uneven deformation, high production costs, and high requirements for rolling mills, and achieve the effects of improving processing and application performance, controlling costs, and simplifying processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

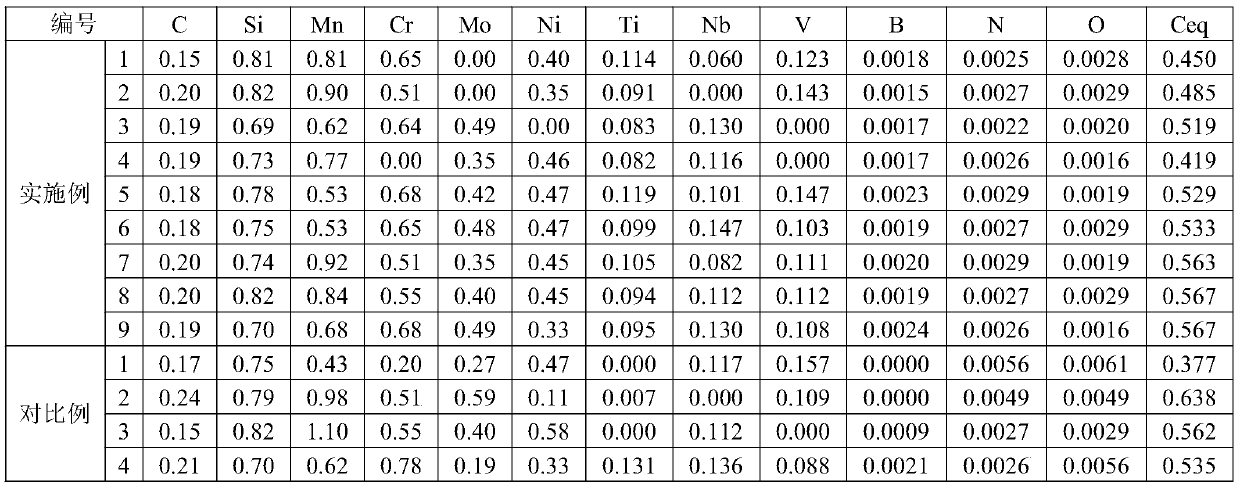

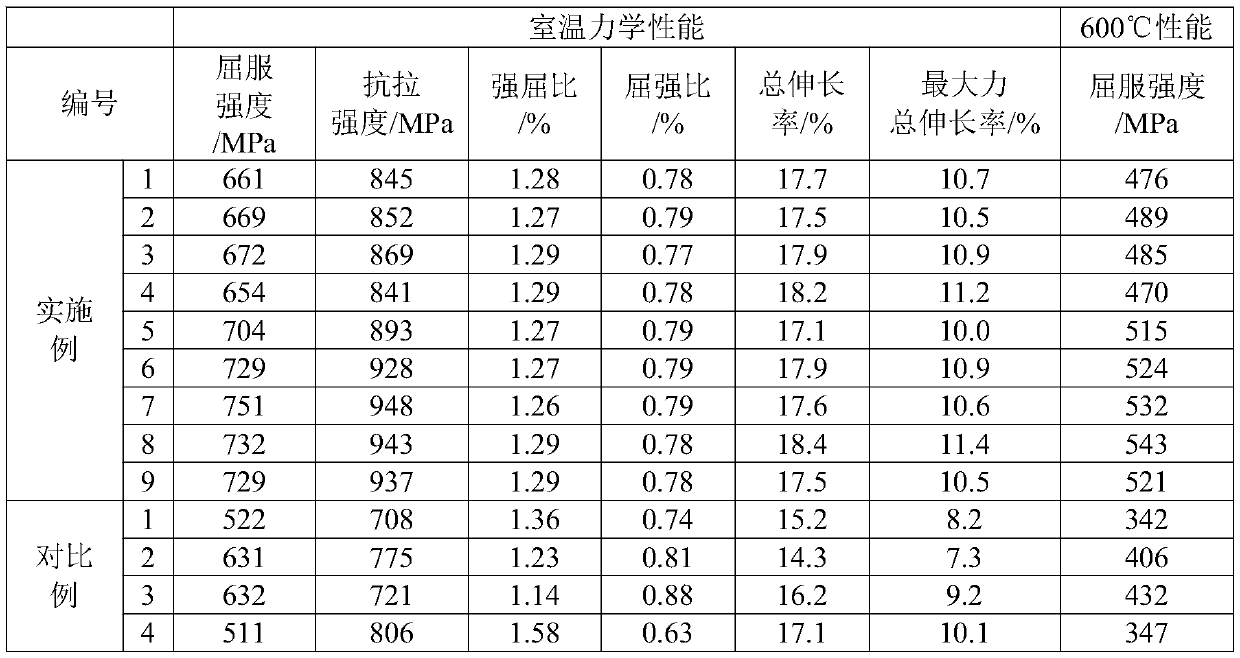

[0037] The technical solutions of the present invention will be further described below in conjunction with the examples.

[0038] The specific components of Examples 1-9 and Comparative Examples 1-4 are shown in Table 1. The short-flow production process of converter / electric furnace smelting+billet continuous casting+cooling bed cooling is adopted, and Embodiment 1-9 is produced according to the following process flow:

[0039] (1) In the smelting and casting process, smelting is carried out in accordance with the composition range and element ratio relationship in the claims. After LF white slag is refined for 5 minutes, ferro-niobium, ferro-vanadium and ferro-titanium cored wire are added for alloying, and LF is refined The range of free oxygen in molten steel is 30-50ppm; the temperature of the continuous casting tundish is 1525-1555℃, the casting speed is 2.8-3.0m / min, the specific water volume of the secondary cooling is 2.1-2.4L / kg, pouring into a cross-section 150mm×1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com