PCB silver electroplating solution containing compound sulfonate brightening agent

A PCB board, sulfonate technology, applied in electrical components, printed circuits, printed circuit manufacturing and other directions, can solve the problems of high solder joint strength, easy decomposition, good soldering performance, etc., and achieve the effect of improving surface gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Configure plating solution:

[0033] (1) Dissolve 45g of silver nitrate in deionized water,

[0034] (2) Dissolve 150g potassium thiosulfate and 55g potassium metabisulfite in deionized water in another container and stir;

[0035] (3) Compound sulfonate brightener, benzothiazolyl-S-(CH 2 ) 3 -SO 3 Na: (CH3) 2 -N-C(=S)-S-(CH 2 ) 3 -SO 3 Na=3:1, total 400ppm, and dissolved in deionized water;

[0036] (4) Mix the brightener solution of step 3 with the solution of step 2;

[0037] (5) Add the solution obtained in step 4 to step 1 under ultrasonic enhancement;

[0038] (6) Add the remaining amount of deionized water to a constant volume according to the aforementioned formula concentration, and add sodium hydroxide to adjust the pH to 9.5-10.5, and let it stand for use.

[0039] 2. Plating process:

[0040] After degreasing and cleaning the PCB board, put it into the plating solution, the current density is 10A / dm 2 . , The plating time is 25MIN.

Embodiment 2-3

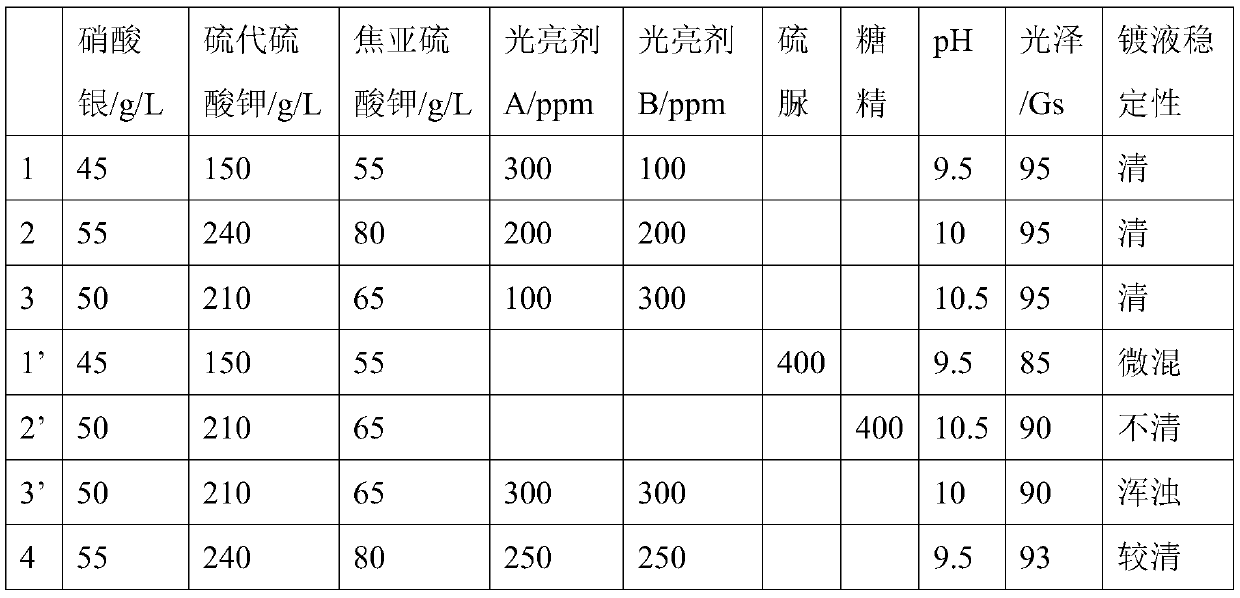

[0041] In Example 2-3, see Table 1 for specific parameters. Other processes are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com