Method and device for preparing continuous carbon nanometer tube fibers through CVD method

A carbon nanotube fiber and liquid-feeding device technology, which is applied in the fields of fiber chemical characteristics, gaseous chemical plating, textiles and papermaking, etc., can solve the problems of low yield of carbon nanotubes, incomplete structure of carbon nanotubes, stress concentration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

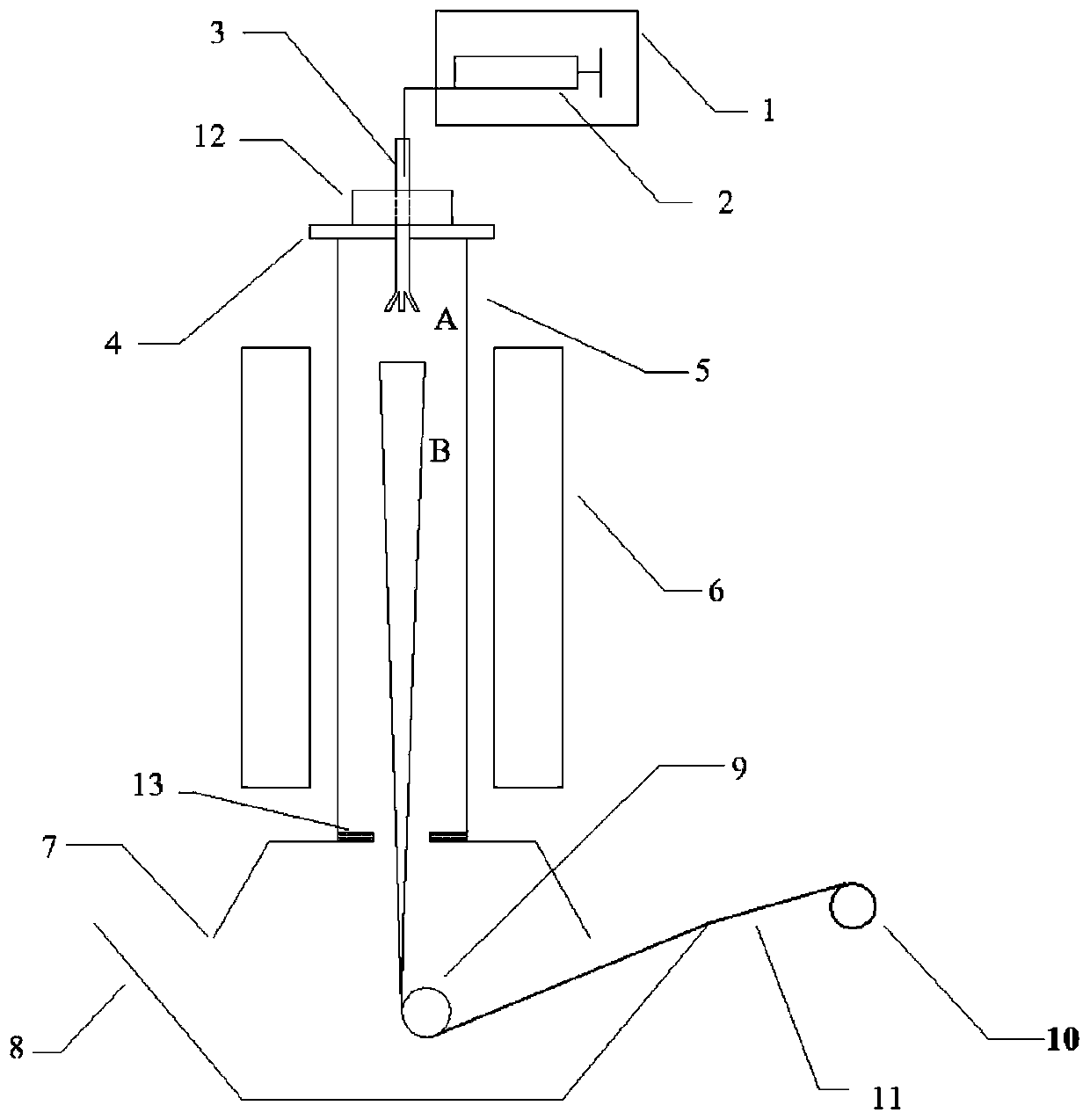

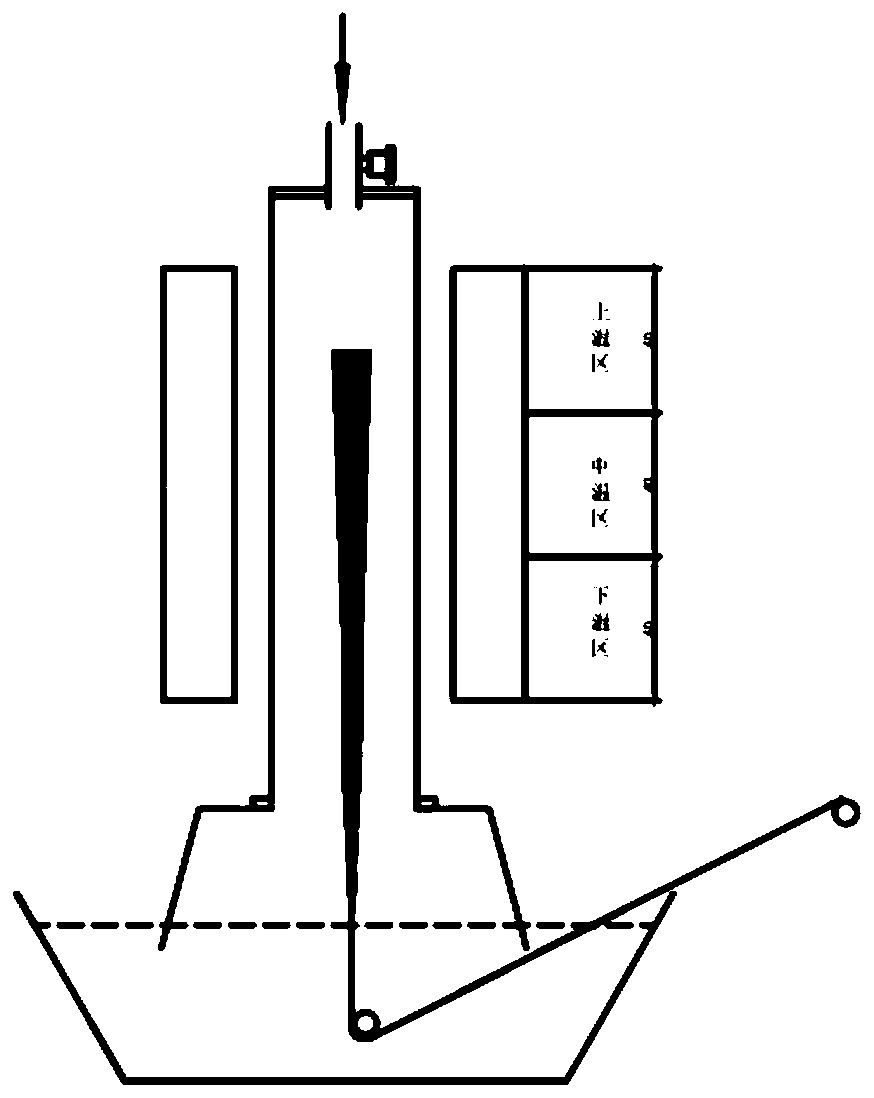

[0036] Add 0.5 g of water to a solution containing 0.25 g of ferrocene, 25 g of ethanol, and 0.15 g of thiophene to make a mixed solution, inject the mixed solution into a needle tube with a diameter of 1 mm through a micro-injection pump, and enter the 900 sccm through three needle tips of 0.5 mm h 2 In the air flow quartz tube, the temperature of the upper temperature zone of the resistance furnace is set to 500°C, and the temperature of the middle and lower temperature zones is set to 1200°C. The reaction can continuously obtain cylindrical carbon nanotube aerogels, which are densified by water and then mechanically wound. Continuous carbon nanotube fibers.

[0037] Concrete preparation process is as follows:

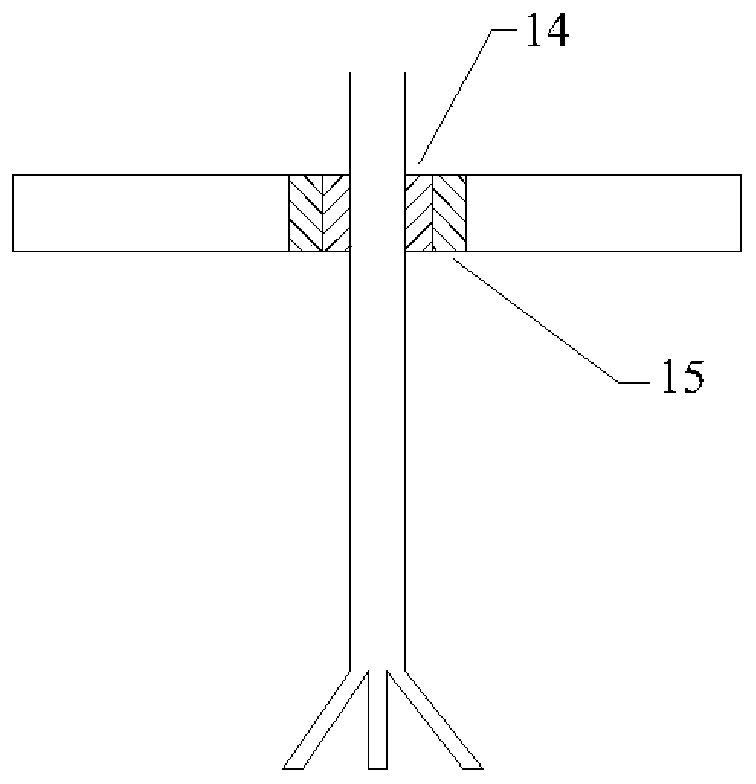

[0038] (1) First check the airtightness of the device, then set the temperature of the upper temperature zone of the resistance furnace to 500°C, and the temperature of the middle and lower temperature zones to 1200°C, and pass hydrogen gas into the quartz tube at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com