Particle swarm optimization manufacturing system double-target production scheduling method based on bionic strategy

A particle swarm optimization, manufacturing system technology, applied in manufacturing computing systems, artificial life, biological models, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

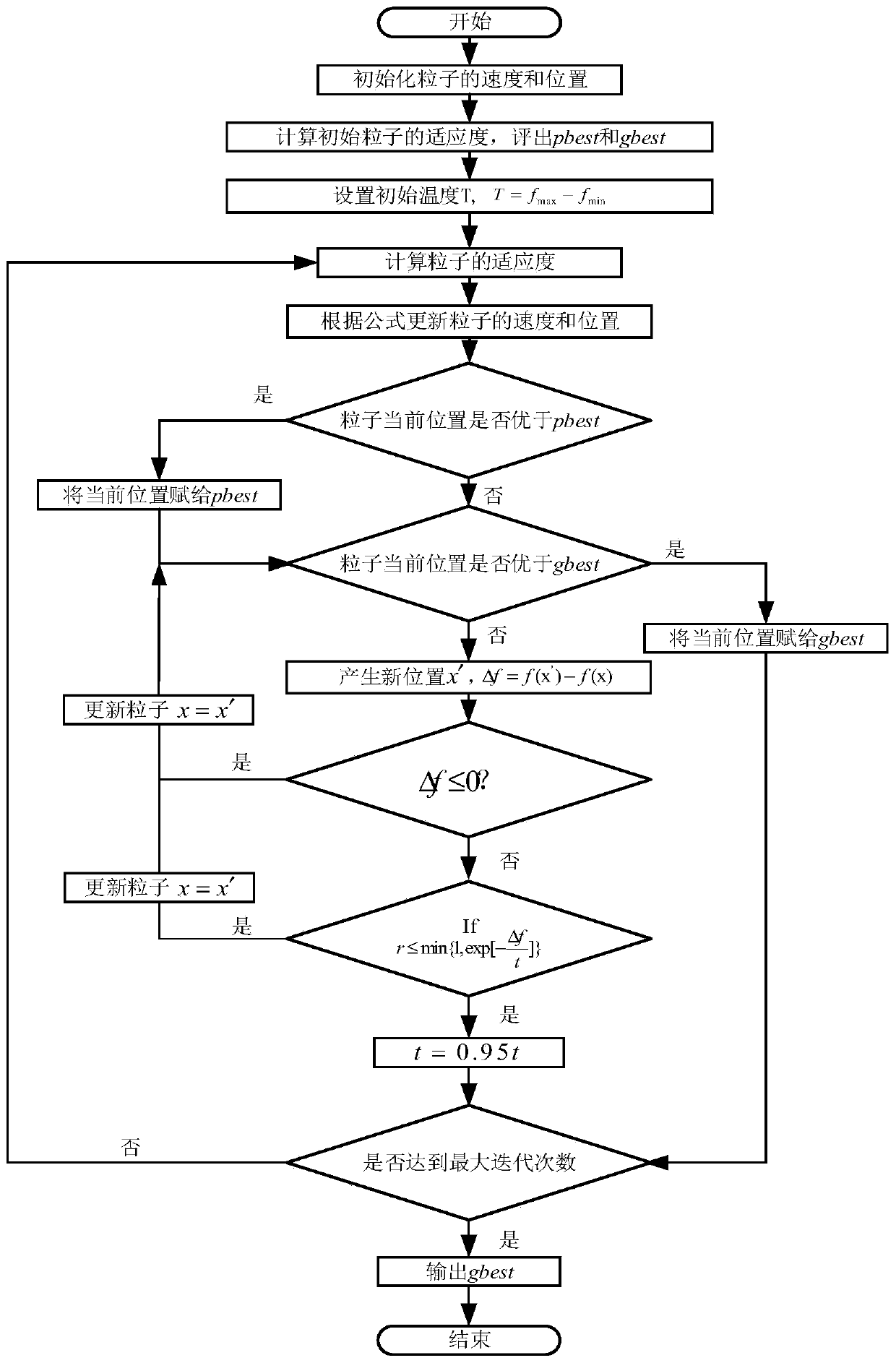

Method used

Image

Examples

Embodiment

[0150] In order to realize the application of the above-mentioned particle swarm optimization algorithm based on the return strategy, the test example is that 10 workpieces need to be processed in a certain workshop. The process route of each workpiece is the same, and the number of machines available for each process is 3. , 2, 4, each machine's spindle speed / rpm, processing time / h, no-load power / KW are not the same. The specific data are shown in Table 1. Now consider the research on energy-saving scheduling in the following three situations.

[0151] Table 1 Processing data of a production workshop in the test case

[0152]

[0153]

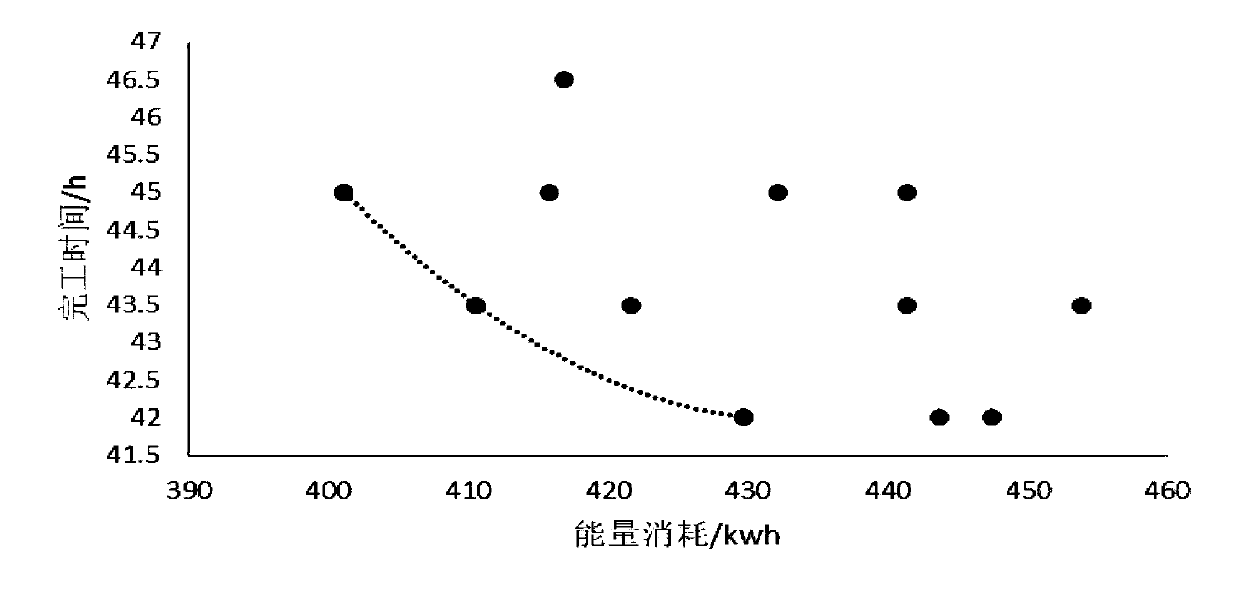

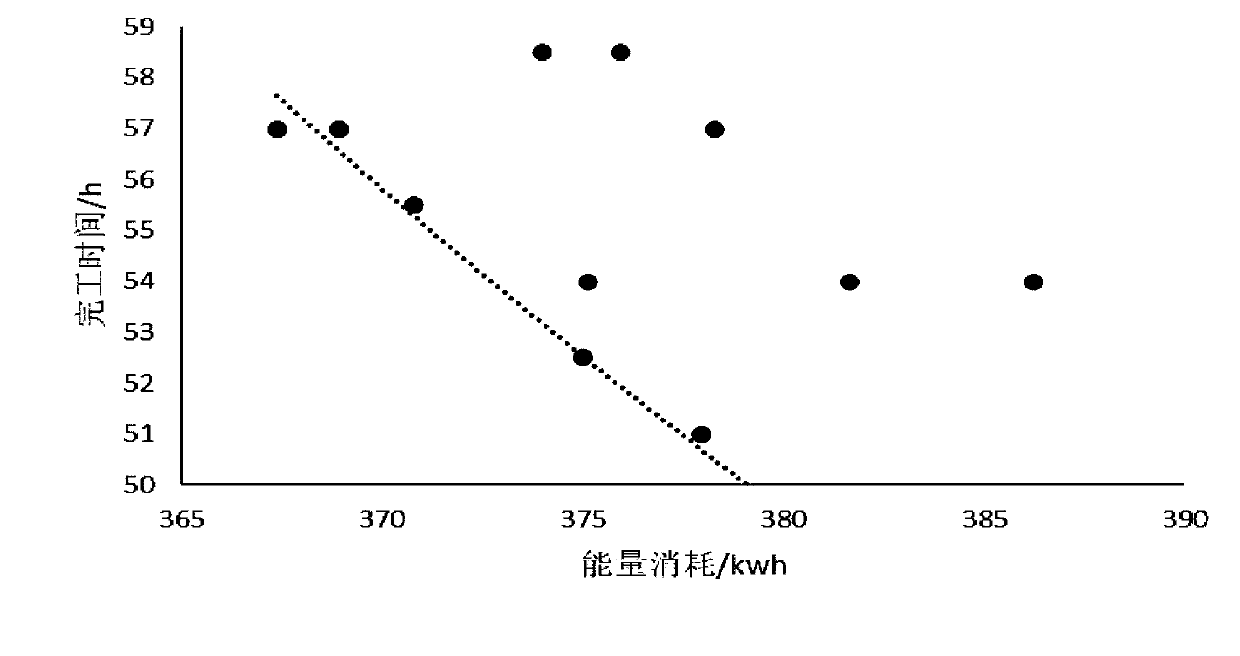

[0154] (1) When the target value of the scheduling plan is biased toward the minimum completion time (σ 1 ≥σ 2 ), use MATLAB simulation to run 12 times, and record the optimal solution of the objective function each time. The spatial distribution of completion time and total energy consumption solution set is as follows: figure 2 sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com